Automated systems and domestic sourcing will contribute to sustainable production for the U.S. manufacturing sector.

By Mike Hook, Sales & Marketing Director, PRAB

Rebuilding the U.S. manufacturing sector has become a critical variable in the equation for post-pandemic economic recovery. Fortunately, after 40 years of decline, manufacturing in the United States is poised to embark on a new chapter.

According to a Thomas Industrial Survey, 60% of the manufacturers and suppliers reported they are likely to return operations to North America. Companies have in fact already begun to shift away from sourcing goods from China in response to the trade war. The Kearney U.S. Reshoring Index authenticates this, reporting that the U.S. manufacturing import ratio (MIR) contracted a little over 7% in 2019, the first decline since 2011.

Despite the challenges elicited by the pandemic, 66% of manufacturers had a positive outlook according to the Third Quarter 2020 National Association Manufacturers (NAM) Survey. But advancing domestic manufacturing comes with some challenges that need to be pre-emptively addressed or they will undermine a company’s ability to grow. Here are five strategies that U.S. manufacturers must consider to position their operations for long-term, domestic growth.

NAM’s Second Quarter Outlook Survey reported that 59.5% of respondents experienced supply chain problems in the first half of 2020. Not surprisingly, manufacturers are taking a hard look at their sourcing protocols.

According to the Reshoring Initiative, most companies base their sourcing strategy (domestic versus global) on ex works costs, wage rates, or landed cost. However, this ignores other assumed costs. It is actually total cost of ownership that needs to be evaluated. Failing to consider other internal and external business considerations such as overhead, balance sheet, risks, and corporate strategy can lead to a miscalculation of offshoring costs that is 20-30% inaccurate. Avoiding production disruptions caused by transportation challenges and quality issues also will improve throughput.

Whether manufacturers choose to offshore or to reshore moving forward doesn’t necessarily need to be a “this or that” choice. A blended approach may be best path forward.

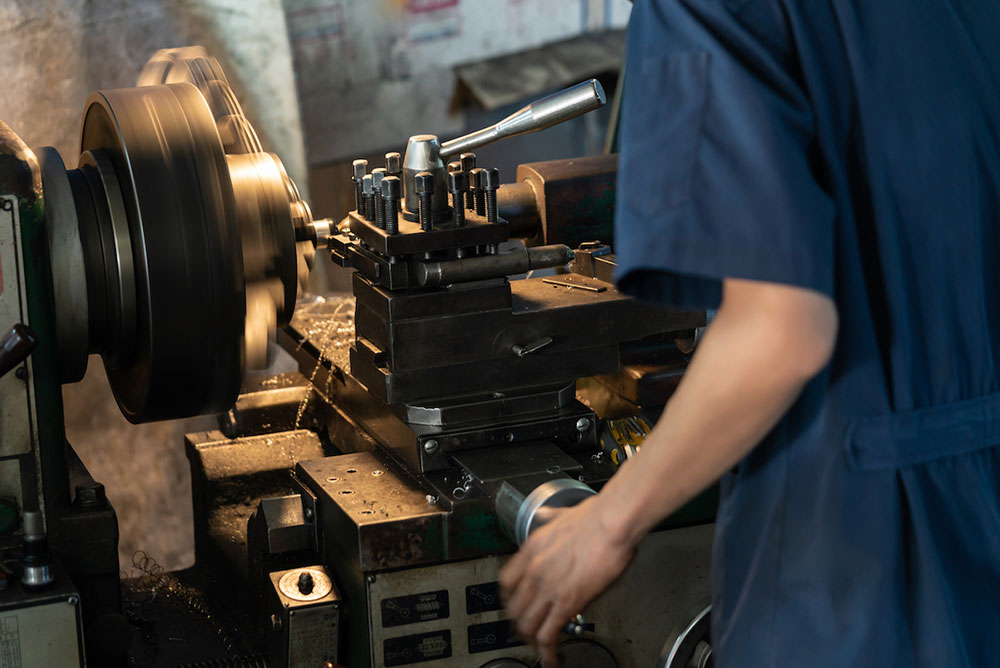

Just as manufacturers need to take a comprehensive look at the total costs of offshoring, a decision to reshore cannot be made independent of other operational cost considerations. For example, regional supply chains enable businesses to split capital and labor costs and to streamline the supply chain, minimize risk, and improve quality. But standing up a regional or local supplier network will take time and investment. Efforts to bring manufacturing in-house will eliminate risk and supply issues. However, it could result in high capital expenditures. Modest in-house machining capabilities such as a single 5-axis mill can cost over $350,000 per year. Equipping a large-scale machine shop can cost upwards of $2 million.

Manufacturers will need to proactively offset costs or generate more revenue in conjunction with supply chain modifications. Waste streams—such as metal scrap, used cutting fluids, and wastewater—are byproducts that operations frequently do not fully leverage. Consult with a supplier of automated waste stream equipment to learn how back-end systems can increase revenue or reduce expenses associated with these valuable materials.

A lack of skilled tradespeople is nothing new to manufacturing. In 2018, Deloitte and The Manufacturing Institute estimated that between 2 million and 2.4 million manufacturing jobs could go unfilled in the next 10 years. How will reshoring increase the need for skilled workers at the same time the pool of skilled manufacturing employees shrinks due to retirements and attrition?

Manufacturers who want to grow the bottom line in the post-pandemic era must adapt operations. Reducing manual labor and creating production efficiencies will be necessary to optimizing allocation of a limited workforce.

Back-end systems that optimize waste streams reduce manual labor, decrease downtime, lower expenses, and, in some cases, generate revenue. Examples of PRAB automated systems that are engineered with ROI in mind, include:

Driven by the demand for lower-price products, cost has been the primary driver for outsourcing production. However, the production savings generated by outsourcing don’t necessarily create lasting value for the customer.

For example, equipment reliability is a top focus at PRAB. The company’s automated systems are constructed in a 114,000-square-foot manufacturing facility in Kalamazoo, MI, where local engineers, machinists, welders, and other skilled tradespeople fabricate equipment that is built to last. PRAB is still providing parts to conveyors that were sold over 57 years ago, and the company has metal chip processing and fluid filtration equipment still operating after 30 years of service life.

Service that customers can count on is also a key part of PRAB’s value proposition. Every aspect of customer care is handled by PRAB—there is zero outsourcing. All of PRAB’s service and technical support is U.S.-based. The company enacted many safety protocols to keep employees and customers safe amid COVID-19. Resolve, caution, and a calculated approach to operating during the pandemic enabled PRAB to continue traveling to help metalworking operations and other manufacturers implement and manage their automated solutions. This approach to consistent product quality and dependable service creates a positive experience for PRAB customers, who in turn are more likely to return to PRAB for future solutions and recommend PRAB to a colleague.

Rising costs and continued instability of global outsourcing will drive growth in domestic manufacturing. In order to compete in this new landscape, however, manufacturers will need to make proactive adjustments ranging from new sourcing strategies to creating efficiencies through automated systems. The companies that get out in front of these adjustments will not only realize fewer disruptions sooner, but also put their operations on the path toward sustainable growth.

About the Author

Mike Hook is the Sales & Marketing Director for PRAB and has more than 15 years of mechanical design and application experience. PRAB is a leading manufacturer of engineered conveyors and equipment for processing turnings, chips, and metalworking fluids. PRAB also designs and builds industrial wastewater recycling systems.

About PRAB

PRAB is a leading engineer and manufacturer of conveyors and chip and fluid management systems. Its customized solutions automate metal handling, reduce labor costs, reclaim and recycle expensive cutting fluids/coolants, and maximize return on recycling metals. With its expertise honed by more than 4,500 installations for the world’s leading OEMs and suppliers, PRAB continuously improves material handling, housekeeping, and compliance to environmental rules and regulations within the automotive, aerospace, medical, electronics, defense, off-road, and energy markets. For more information about PRAB, visit prab.com.

Scott Ellyson, CEO of East West Manufacturing, brings decades of global manufacturing and supply chain leadership to the conversation. In this episode, he shares practical insights on scaling operations, navigating complexity, and building resilient manufacturing networks in an increasingly connected world.