Procurement is often over-looked or underappreciated, yet it can play a leading role in efforts to address volatility and capture value.

By McKinsey & Company partner Roman Belotserkovskiy

Companies are facing yet another economic challenge—inflation, which is accelerating and driven by a myriad of factors from rising commodity prices and supply-chain disruptions to tightening labor markets. Companies are facing an imperative to build operational resilience.

Although often over-looked, the procurement function is in a unique position to help companies navigate economic volatility, changing market conditions, or shifts in consumer behavior, by applying a much broader set of levers to create value. With research from McKinsey Global Institute estimating that significant disruptions to production now occur every 3.7 years, on average—now is the time to give procurement a bigger seat at the table.

Here are key ways procurement can help companies achieve greater resilience.

The first step to building next-generation procurement is to identify the highest-priority business needs, using the digital-solution tools that generate actionable insights. This allows teams to quantify the extent to which inflationary pressure on materials, services or other costs may impact supplier prices will affect supplier prices. For example, using dashboards to give users easy access to regularly refreshed data and insights including how spending has evolved over time for each supplier, the gap between actual and theoretical spending based on should-cost prices for specific suppliers, and the impact of single sourcing on total spending.

This level of analysis can help buyers identify and prioritize opportunities across all categories, and allows them to focus on value-adding activities that can create new savings opportunities. For example, bundling separate purchases to enable volume discounts and using should-cost models based on current prices to understand suppliers’ underlying cost exposures can create new saving opportunities.

A more sophisticated approach creates an embedded-cost analysis for further illumination about what is driving prices, what is happening with those cost drivers, and how to use these insights in negotiations. These sorts of tools helped a basic-materials company respond to a 40 percent price increase from a critical supplier. The company’s detailed analysis of the supplier’s embedded costs revealed that the supplier had significantly overstated raw materials’ share of overall price economics. Applying this insight in its negotiations, the company was able to mitigate the proposed price increases by almost one-quarter.

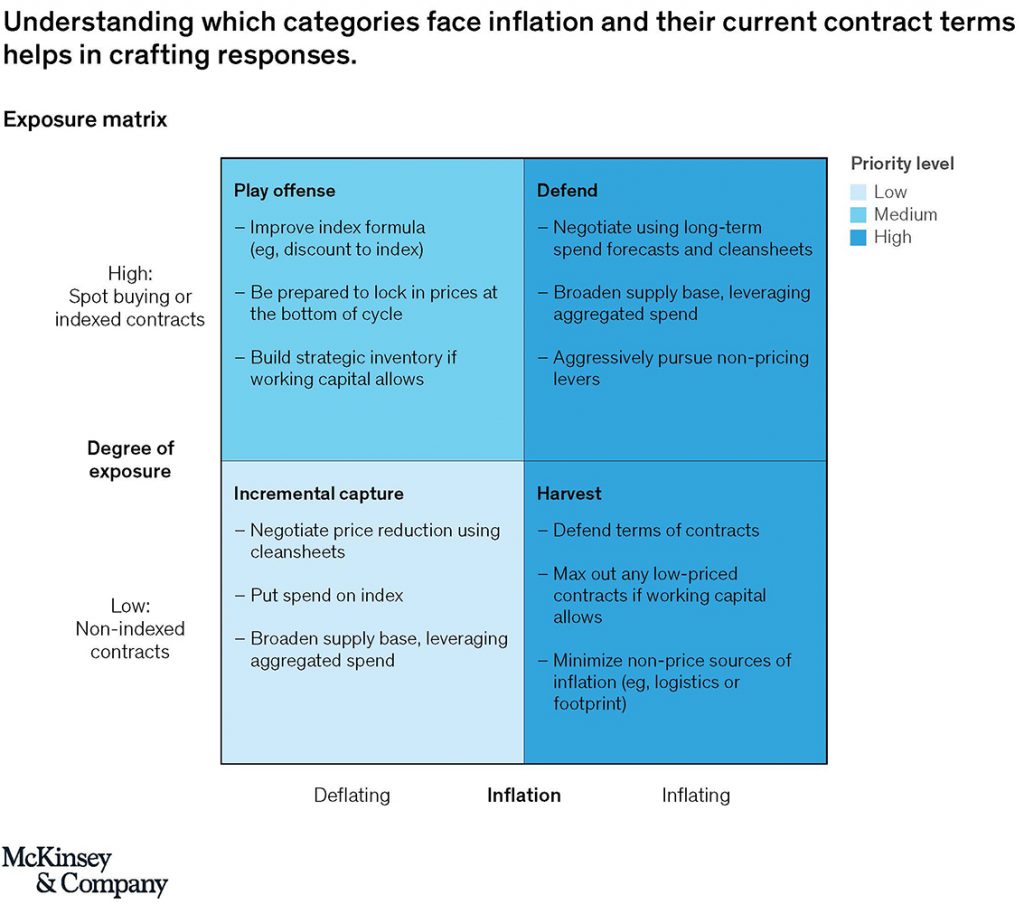

One of the most promising early-stage approaches within this broad set of actions is a procurement nerve center. The structure brings together specialists across the value chain—from supply chain, planning, finance, operations, and engineering—to triage supply-availability problems for raw materials, components, and related inputs. Within the first week, the nerve-center team prioritizes categories in a centralized, strategically informed way that is based on an exposure matrix considering inflation (or deflation) and the degree of exposure to the market forces.

At a basic-materials company, the nerve center brought together a team of specialists from the supply chain, planning, finance, operations, and engineering. On day one, the team set up the working infrastructure, including the activity cadence and dashboards for initiative tracking. Over the following weeks, the team was able to reduce a major supplier’s price increase by more than 20 percent. And in similar fashion, a component manufacturer’s nerve center successfully navigated supply and price volatility in both semiconductors and steel.

When facing inflationary pressures, a nerve-center team collaborates to capture cost savings, find and approve alternative commodities and their sources, and develop deeper partnerships with key suppliers to generate additional sources of value. The nerve center brings together a team of specialists from the supply chain, planning, finance, operations, and engineering. On day one, the team sets up the vital working infrastructure, including the activity cadence and dashboards that track progress on initiatives. From that point, impact can take as little as five weeks.

Companies that implement nerve centers effectively can structurally improve their cost bases, protect and enhance margins, and drive organizational alignment.

In a world of growing uncertainty, procurement plays a vital role in company’s pursuit of resilience, but only if it is armed with the right capabilities for pursuing sophisticated approaches. Investing in stronger, future-ready practices and capabilities can pay off in the short term, and enable functions across the enterprise to capture value. Companies that do this effectively will be well positioned to accelerate their recovery out of today’s challenging times and be prepared for whatever tomorrow may bring.

Roman Belotserkovskiy is a partner at McKinsey & Company, based in Atlanta. He has extensive experience in the energy sector and leads McKinsey’s procurement and supply-management work within the Electric Power & Natural Gas Practice. Roman has deep expertise in manufacturing and industrial operations, and the integration of procurement optimization levers into operational-performance transformations across all power generation technologies, from fossil to renewable to nuclear power generation.

Contact:

https://www.mckinsey.com/business-functions/operations/our-insights

Scott Ellyson, CEO of East West Manufacturing, brings decades of global manufacturing and supply chain leadership to the conversation. In this episode, he shares practical insights on scaling operations, navigating complexity, and building resilient manufacturing networks in an increasingly connected world.