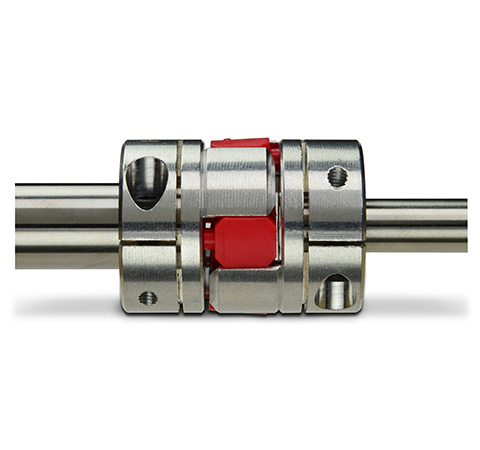

Jaw couplings are ideal for systems that experience hard starts, hard stops or reversals in applications including medical and robotics.

Marlborough, Massachusetts. Ruland zero-backlash jaw couplings are a three-piece assembly designed to accommodate high acceleration and deceleration curves that result in peak torque. Jaw couplings are ideal for systems that experience hard starts, hard stops, or reversals, including in medical, semiconductor, test and measurement, and robotics applications.

Ruland’s balanced jaw coupling design consists of two hubs and an elastomeric insert known as “the spider.” The hubs are machined through a proprietary process that creates a curved jaw profile, enabling a press fit with the spider for zero-backlash operation. Start and stop applications in servo motor drive systems will often experience high peak torque loads caused by inertia, friction, and high acceleration/deceleration rates. The spider dampens these impulse loads to minimize shock to the motor and other sensitive components. Spiders are available in three durometers – 85 Shore A for greatest dampening, 92 Shore A for a balance of dampening, torque and torsional stiffness, and 98 Shore A for a small amount of dampening and the highest torsional torque and stiffness.

Jaw couplings offer a high level of customizability by allowing users to combine clamp and set screw hubs with various bore options, including inch, metric, keyed, and keyless bores, with sizes from 1/8 inch to 1-1/4 inch and 3 mm to 32 mm. They are considered failsafe as the interlocking hubs provide direct power transmission for controlled shutdown if the spider fails. Replacing the spider restores the original performance characteristics of the coupling, significantly reducing maintenance costs when compared to coupling styles that require complete replacement.

All Ruland jaw couplings are RoHS3 and REACH compliant. Fully custom jaw coupling designs are available for users seeking special materials, sizes, or specifications. Jaw couplings are part of Ruland’s complete zero-backlash coupling line, including rigid, bellows, disc, beam, oldham, controlflex, and slit couplings. Full product information, 3-D CAD files, and additional technical specifications are available at ruland.com.

Product link:

https://www.ruland.com/servo-couplings/jaw-couplings.html

About Ruland:

Ruland Manufacturing Co., Inc. is a privately owned family company founded in 1937. Ruland has carefully and responsibly manufactured high performing shaft collars, rigid couplings, and motion control couplings for the past 40 years. Ruland’s product line was recently expanded to include a variety of machine components from select manufacturers that align with Ruland’s performance and quality standards.

Contact:

Ruland Manufacturing Co., Inc.

6 Hayes Memorial Drive

Marlborough, MA 01752, USA

Phone +1 508 485 1000

Fax +1 508 485 9000

E-mail marketing@ruland.com

Internet www.ruland.com

PR contact:

TPR International

Christiane Tupac-Yupanqui

PO Box 11 40

82133 Olching, Germany

Phone +49 8142 44 82 301

E-mail c.tupac@tradepressrelations.com

Internet www.tradepressrelations.com

Scott Ellyson, CEO of East West Manufacturing, brings decades of global manufacturing and supply chain leadership to the conversation. In this episode, he shares practical insights on scaling operations, navigating complexity, and building resilient manufacturing networks in an increasingly connected world.