Capital projects regularly overrun budgets and schedules by 30-45%. New technologies bring fresh ways to address these shortcomings.

By Daniel Ahmoye and Kevin Stokvis, McKinsey & Company

Capital projects regularly overrun their budgets and schedules by 30 to 45 percent.1 With an estimated pipeline of $130 trillion capital spend on infrastructure and construction arriving over the coming decades, that’s a multi-trillion dollar problem. Thankfully, the smart application and development of new technologies is bringing fresh ways to address such systemic shortcomings.

In a word, complexity. Large projects require an average ecosystem of ~180 organizations, including owners, contractors, subcontractors, trades, specialist resources, regulatory bodies, and arms of government, all working together. With large projects, there are problems to solve and trade-offs to be made daily—emanating from within the project itself, or coming from outside in the form of supply chain delays, rising cost of goods, or labor shortages, for example.

Visibility and transparency are the vaccines for delays and overruns. The earlier and more clearly owners and contractors can see a problem, the quicker and more incisively they can act to mitigate its impact, swerve it, or plan around it. The same, of course, goes for capitalizing on opportunities. Unfortunately, in most execution or delivery models, project leaders are likely to receive important information about project risks, problems, or even opportunities that is garbled or incomplete, and often far too late to be able to address them properly.

A number of reporting and communication issues are at play here. Critical data is often collected in non-standard ways, performance measures are often disparate across operations, information can be siloed in different systems, multiple stakeholders with different needs are inevitably looking for different insights from project data, and on-the-ground discipline when it comes to tracking critical metrics can be patchy. These are just a few examples of what often doesn’t work well.

The execution of large projects can be improved by changes in three areas:

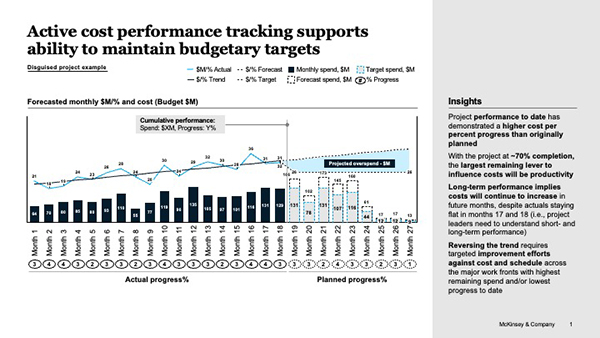

It all starts with setting up data ingestion and analytics that provide transparency into progress and performance data. The right technical system increases the speed of ingestion, aggregation, and visualization of project data from disparate sources. Only then can enhanced analytics, insights, and agile decision-making flow. Now, a wide range of risks and pressures can be flagged early, and to the right people. In such an environment, management teams can scenario plan interventions with greater clarity and confidence, foreseeing improvements as well as problems—productivity gains at key stages, or sharing personnel and equipment between projects, for example.

Projects that want to fully benefit from the right digital technology and associated systems need to start early, creating a flywheel for ongoing improvements. The approach can also be applied to improve and remedy issues in ongoing projects. For example, a chemical company facing cost overruns and delays in the construction of a large petrochemical facility set up a “digital control tower” that helped it identify, manage, and deliver more than $75 million in cost savings over the remaining course of the project—and it found those opportunities quickly.

It’s worth emphasizing that the solutions for many projects, when it comes to cost and time overruns, are not a great leap from where many projects already are. Setting up an effective control tower, for instance, can take as little as two or three weeks, without requiring significant additional technical infrastructure.

Data alone will not save the day. Overruns will be avoided or minimized only if the right decisions are taken in a timely matter.

Effective project performance management processes take an integrated view, looking across construction phases and project areas. They are structured to emphasize forward-looking problem solving, with information cascaded to enable better decision making at the right levels. And those decision-making processes are defined and understood, as are the formats for performance dialogues and routes for escalation. Data is presented in appropriate granularity for each level.

Crucially, the project performance management processes and the digital control tower are closely linked. This is how project teams can avoid lacklustre discussions based on incomplete information, and represents an opportunity for management teams to move out of a defensive mode and start focusing more on productivity and how to better deliver the project.

If the solutions for fewer and less costly overruns are within reach, what’s stopping organizations and the construction sector as a whole from realizing so much value left on the table? That transparency and insights flow from new technical solutions and sound management is indisputable. But organizational and individual capability building is needed to turn these insights into results.

Personnel need to know how to interpret data, how to manage constructive, fact-based discussions, how to create and modify complex plans and schedules. Frontline teams need lean construction skills to unlock performance progress through standardization and continuous improvement. Mindsets and behaviors are just as critical. To keep projects on track, leaders need to be activists, incentivized to engage with their teams to improve frontline performance.

A project data and analytics system is a great place to begin your journey to enable these three critical elements. Indeed, establishing an effective data and analytics system has the power start the transformation of wider working practices. At McKinsey, we have seen several examples of better ways of working spreading across clients’ organizations, projects, and portfolios, spurred by digital control towers. And if a control tower is where you embark, the lodestar for your voyage is transparency. Huge savings in cost and time on large projects are possible, but only if the right people can see what they are dealing with earlier and more clearly than they can currently.

Daniel Ahmoye

Partner

Based in Calgary

Kevin Stokvis

Partner

Based in Calgary

1 https://www.mckinsey.com/capabilities/operations/our-insights/here-comes-the-21st-centurys-first-big-investment-wave-is-your-capital-strategy-ready

Scott Ellyson, CEO of East West Manufacturing, brings decades of global manufacturing and supply chain leadership to the conversation. In this episode, he shares practical insights on scaling operations, navigating complexity, and building resilient manufacturing networks in an increasingly connected world.