Volume 27 | Issue 1

Click here to read the complete illustrated article or continue below to read the text article.

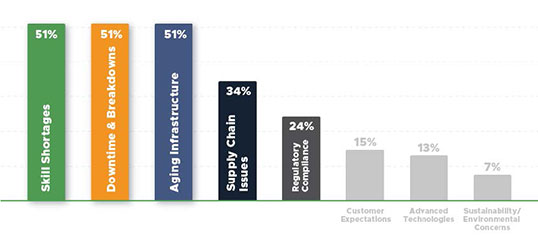

In recent years, the world of manufacturing and facilities maintenance has evolved at a rapid pace with the introduction of AI and other advancing technologies. While it may be tempting to look out for the “next big thing”, a recent report showed that many maintenance teams are actually focusing on more foundational elements that will pave the way for future innovation. Limble’s State of Maintenance in Manufacturing and Facilities report surveyed over 250 maintenance professionals and found that more than half of them identified downtime, skilled workforce shortages, or aging infrastructure as one of their top three challenges. Most maintenance teams are less concerned with emerging technologies and more interested in the fundamental strategies they can employ to solve today’s most pressing challenges while also preparing themselves to embrace future innovations.

Minimizing equipment downtime stands as one of the most prevalent challenges for manufacturing and facility professionals, with 51.2 percent of respondents listing it as a top challenge, according to Limble’s research. Maintenance professionals have struggled with this issue for as long as the industry has existed, and the reason is quite simple: when machines are down, operations and production are halted, which directly impacts revenue. Unplanned downtime costs the manufacturing industry billions of dollars each year. Downtime can also put a strain on relationships and contracts with partnering companies due to the obstructed flow of input and output.

Equipment downtime can be a result of operator errors, insufficient employee training, or old, faulty equipment. Most commonly, however, a fully reactive maintenance strategy is causing avoidable unplanned downtime. This explains why 78 percent of the companies surveyed that are looking to reduce downtime are leveraging preventive maintenance as a top strategy. Preventive maintenance involves inspecting and repairing assets before issues arise to keep them in optimal working condition. The U.S Department of Energy estimates that preventive maintenance measures can result in up to 30 percent reduction in maintenance costs, 45 percent fewer malfunctions, and up to 75 percent increase in uptime. Common preventive maintenance tasks, such as cleaning, inspections, and lubrication are essential for maximizing equipment performance and extending its lifecycle.

While those tasks may seem simple, it can be difficult to manually implement a preventive maintenance program. From documenting procedures, checklists, parts, and tools, to prioritizing preventive maintenance tasks against unplanned Work Orders, to scheduling and assigning the tasks and tracking completion, a preventive maintenance program may seem daunting. This is where the technology comes in to introduce automation and streamline processes. Tools such as computerized maintenance management systems (CMMS), can automate PM scheduling, offer customizable PM templates, and keep detailed logs of all asset and maintenance history. This eliminates the administrative burden of manually implementing or optimizing a preventive maintenance program while helping to ensure proper equipment maintenance and, ultimately, reduce downtime. In the event unplanned downtime does occur, it is also important to have emergency maintenance procedures and backup equipment in place to help drive speedy responses to critical issues and get equipment back up and running as quickly as possible.

Workforce shortages continue to pose a significant challenge for many industries, including manufacturing and facilities management. The research showed that more than 50 percent of maintenance professionals surveyed considered workforce shortages as one of their top three challenges. A lack of qualified staff not only impacts essential daily tasks, but also compromises product quality and service delivery. Organizations also may see increases in overtime labor costs as limited team members are required to work additional hours. Labor shortages and worker turnover can result in limited internal knowledge and familiarity with equipment, standard operating procedures, and digital tools. This can impact the teams productivity, efficiency, and the organization’s ability to maintain a competitive edge in their industry.

To address the workforce issue, companies are ramping up their recruitment and retention efforts, and offering more competitive compensation and benefits to attract new talent. Recognizing the value of skilled workers in driving operational excellence and fostering innovation, maintenance teams are also looking to upskill their current personnel by providing opportunities such as training sessions and mentorship programs. Through these strategic initiatives, manufacturing and facilities teams can overcome the skilled workforce shortages and equip their workers with the knowledge they need to increase their impact.

Companies can also address this issue by investing in tools that help maintenance teams do their jobs more efficiently. For example, the survey showed current CMMS users were 32 percent less likely to cite workforce shortages as a top challenge compared to those not using a CMMS. This is because CMMS platforms boost productivity by 41 percent, helping maintenance teams accomplish more with less, ultimately reducing the pain of workforce shortages.

The research also found aging infrastructure to be a top challenge for more than half of the maintenance professionals surveyed. Upgrading infrastructure in a financially strategic and responsible manner can be challenging but is necessary for organizations to sustain reliable operations, alleviate logistical strains, ensure regulatory compliance, and uphold worker safety. Strategically investmenting in upgrading or replacing aging infrastructure can also help organizations save money in the long run. Depending on the piece of equipment, it may cost more to maintain it between labor hours and consumable parts usage than to replace the equipment entirely.

Proactive maintenance and strategic investments in upgrades were the favored strategies among manufacturing professionals to address aging infrastructure challenges. To make the most of these investments, strategic maintenance strategies supported by technology and data insights will take on an even more critical role. For example, technologies like CMMS can collect asset performance data, record maintenance activity history, and forecast future costs. Understanding time and budget allocation by asset, and identifying equipment that is requiring excessive man hours and parts inventory, can help maintenance teams make informed ‘repair vs. replace’ decisions. CMMS platforms also enable maintenance teams to automate PM scheduling and easily leverage proactive maintenance to get the most out of their existing infrastructure.

Embracing digital transformation is vital for organizations to remain competitive in today’s manufacturing and facility maintenance landscape. While the top challenges facing manufacturing and facility maintenance professionals have existed for many years, embracing foundational technologies like CMMS can play a critical role in solving them. Organizations should adopt a proactive, holistic approach that combines technological investment with a focus on fundamental preventative maintenance principles and workforce development. This shift will allow manufacturing and facilities management organizations to overcome the day-to-day challenges they are facing, and remain competitive in the ever-evolving industry landscape.

Bryan Christiansen is a self taught full stack developer turned marketer turned entrepreneur. Bryan is the founder and CEO of Limble CMMS, the leader in CMMS software which empowers the unsung heroes that support the world. Limble has grown to having thousands of users in just a few short years.

Scott Ellyson, CEO of East West Manufacturing, brings decades of global manufacturing and supply chain leadership to the conversation. In this episode, he shares practical insights on scaling operations, navigating complexity, and building resilient manufacturing networks in an increasingly connected world.