Tailor-made reactive resins and turnkey production systems for ultra-fast sealing, casting, and bonding at Battery Show Europe 2024 – Hall 6.

Grafenberg, Germany. Sealing foams, electro casting resins, gap fillers, and adhe- sives as well as production systems with integrated dispensing technology for sealing, casting, and bonding electric mobility components will be presented by the international RAMPF Group at Battery Show Europe, June 18 to 20, in Stuttgart – Hall 6 / Booth 6-A46.

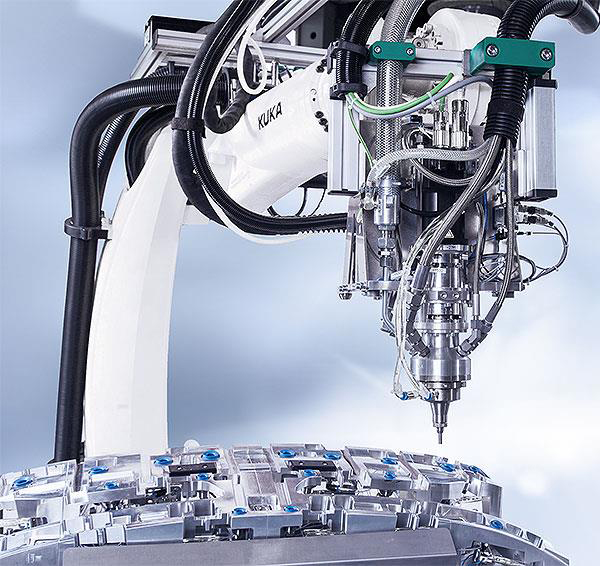

RAMPF Production Systems is a leading international supplier of high-performance, low-maintenance process technology for the precise mixing and dispensing of one-, two-, and multi-component reactive plastic systems – regardless of viscosity and density.

In addition to the core competence of mixing and dispensing technology, RAMPF provides product- specific automation concepts with integrated parts transport and heat treatment, assembly and joining technology, as well as logistic and quality assurance solutions.

Customer-specific solutions also include integrating surface activation processes as well as testing and measuring technology to safeguard production processes.

RAMPF Production Systems has designed and produced highly complex systems integrating dynamic or static mixing technology for leading OEMs and suppliers:

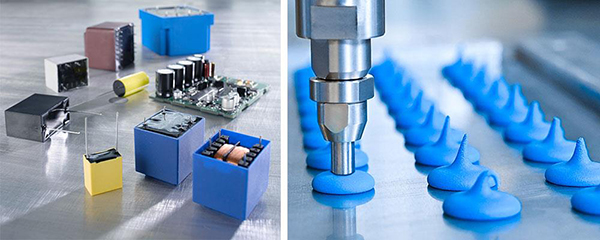

Liquid to highly thixotropic and compact gaskets based on polyurethane (RAKU® PUR) and silicone (RAKU® SIL) offer maximum long-term protection against moisture, dust, and chemicals. The high- performance products from RAMPF

Electro casting resins based on polyurethane (RAKU® PUR), epoxy (RAKU® POX), and silicone (RAKU® SIL) offer effective and long-term protection of electrical/electronic components and ensure optimum thermal management and high thermal endurance.

Gap fillers based on silicone (RAKU® SIL) exhibit first-class thermal conductivity, very high long-term temperature resistance, a wide temperature application range, very good electrical properties, low Shore hardness, thixotropic behavior for excellent processability with maximum dispensing speeds, and fast curing at room temperature (accelerated curing by heat possible).

RAKU® PUR, RAKU® POX and RAKU® SIL brand adhesive exhibit excellent adhesion properties, high strength, and outstanding temperature and chemical resistance. The adhesives can be formulated and manufactured in a wide range of properties and adapted to a wide variety of requirements.

Visit RAMPF at Battery Show Europe 2024 from June 18 to 20 in Stuttgart – Hall 6 / Booth 6-A46!

The RAMPF Group stands for Chemical & Engineering Solutions and caters to the economic and ecological needs of indus- try with four core competencies:

RAMPF has subsidiaries in Germany, the United States, Canada, China, Japan, and Korea.

All RAMPF companies are united under a holding company – RAMPF Holding GmbH & Co. KG – based in Grafenberg.

Published by:

RAMPF Holding GmbH & Co. KG

Albstrasse 37

72661 Grafenberg

Germany

T + 49.71 23.93 42-0

F + 49.71 23.93 42-2050

E info@rampf-group.com

www.rampf-group.com

Your contact for images and further information:

Benjamin Schicker

RAMPF Holding GmbH & Co. KG

Albstrasse 37

72661 Grafenberg

Germany

T + 49.71 23.93 42-1045

F + 49.71 23.93 42-2045

E benjamin.schicker@rampf-group.com

From tradition to transformation Sequoia Brass & Copper has stood for excellence in American manufacturing. In this episode, we sit down with Kim MacFarlane, President of Sequoia Brass & Copper, to hear the inspiring story of a family-owned company founded by her father, built on craftsmanship, trust, and a relentless commitment to quality. Kim shares how she’s guided the company through the challenges of modern industry while honoring its heritage, and how the next chapter will be carried forward by her son Kyle. This is more than a story of brass and copper; it’s about resilience, innovation, and the enduring strength of family legacy. If you’ve ever wondered how tradition can meet the demands of today’s industry hit play and be inspired.