What if safety wasn’t something you react to, but something you predict? AI is turning that ‘what if’ into ‘what’s next.’

The clang of metal echoes through the factory floor. Sparks fly as robotic arms weld steel with surgical precision. A forklift rumbles by, narrowly avoiding a worker who’s momentarily distracted, wiping sweat from his brow —just another day in one of the most high-risk workplaces on Earth.

Moments like these happen every hour in factories across the globe. Some pass without incident. Others turn into near-misses. And sometimes, they end in tragedy.

In manufacturing, safety has always walked a tightrope between human vigilance and mechanical danger. The International Labour Organisation estimates that about 3 million people die every year due to workplace accidents and illnesses.

The Bureau of Labour Statistics mentioned that manufacturing industry based areas like warehousing and transportation, causes about 12.9 fatal injuries per 100,000 full-time workers.

Now, something new is entering the scene—not wearing hard hats or safety vests, but existing quietly in lines of code, sensors, and cameras. Artificial Intelligence or AI in workplace safety is stepping in, not to replace workers, but to protect them in ways once impossible.

This isn’t just innovation. It’s a factory reset—a fundamental rewiring of how we think about workplace safety.

Historically, workplace safety in manufacturing has focused on its physical barriers, like compliance with helmets, gloves, railings, and warning signs. While these measures remain critical, they operate largely in a reactive paradigm. Someone slips during a task, a near miss is recorded in writing, and then the safety team responds.

AI, however, is known to flip this sequence.

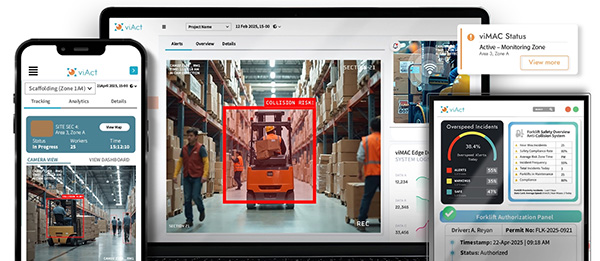

The modern systems using AI in workplace safety integrate different tools for monitoring in real time. For instance, an Edge AI device is known for its portability and on-site processing abilities. Similarly, using them in blind spots to detect hazards before they manifest is just another one of the features of AI in manufacturing safety.

Imagine a pedestrian worker about to step into a danger zone marked within a 3 meter radius by AI due to the ongoing forklift operations. The edge AI device attached to the front and rear ends of the forklift can process up to 30 frames per second, allowing for real-time detection of human presence and movement patterns.

While the worker would be notified in his smart watch, the operator can see a flash on his in-cabin display.

In one such deployment at a Southeast Asian food & beverage plant, it scanned over 15,000 proximity events per month, reducing unauthorized zone entries by over 60% within the first quarter of implementation.

“In 2025, we’re have an era of safety where it isn’t just about just reacting to the incidents but predicting them and preventing them with great precision. AI gives us the power to understand risks not just statistically, but situationally.” quotes Gary Ng, CEO of viAct.

Traditional Behaviour Based Safety (BBS) programs relied on manual observation and post-incident audits. But humans are prone to bias, fatigue, and inconsistency.

But when it comes to AI, it is trained on thousands of hours of operational data, and now augments these systems by identifying unsafe behaviors in real-time.

A worker sprinting across a conveyor belt to save time may go unnoticed by a supervisor, but not by an AI-enabled safety management system. These systems are 90% more effective in flagging such violations immediately, helping EHS teams intervene before habits turn hazardous.

Similarly, behavioural AI-based safety systems can detect ergonomic violations like a worker bending incorrectly, overreaching, or lifting loads without proper posture. Over time, this data not only reduces immediate risks but also contributes to a more health-conscious work culture.

Hugo Cheuk, COO of viAct rightly remarks, “AI in workplace safety allows us to look beyond the event and understand the environment and decisions leading up to it. It’s not about surveillance; it’s about insight. And insight that helps us coach, correct, and care is irreplaceable.”

When we picture a manufacturing site, different vehicles and machines from pallet jacks, forklifts, mobile-elevated work platforms (MEWPs), to automated guided vehicles (AGVs) and conveyor belts, operating in close proximity can be expected.

Such a situation on a factory floor requires proactive vigilance. While training helps to reduce the chances of vehicle collisions to humans, machines or other vehicles, it’s often not enough in high-paced environments where visibility is compromised and alertness wanes.

Here, workplace safety AI offers a revolutionary advantage.

If a forklift moves too close to a pedestrian, AI can trigger visual and audio alerts instantly. More advanced systems automatically reduce vehicle speed or trigger emergency brakes based on proximity risk.

A successful instance of a leading Malaysian automotive manufacturer who integrated AI-powered proximity sensors and vision AI based safety systems in its assembly lines is worth a mention. Within just six months, the company reported a 43% decrease in vehicle-to-pedestrian near-misses and a 28% improvement in response time during critical movements.

In fact, in an electronics factory in Singapore, using AI-enabled anti-collision systems with automated guided vehicles (AGVs) recorded zero collision-related downtime in over 12 months of deployment.

These aren’t speculative use cases—they are active in progressive manufacturing units where downtime and danger are equally unaffordable.

For every accident recorded, countless near misses escape documentation. These can be well-considered, the whispers before the scream, the quiet signals across the floors that something isn’t right.

Traditional methods often struggled to capture them due to added levels of tasks, and no one wishes to fill out another form at the end of a long shift.

But with the implementation of AI in manufacturing safety, computer vision systems ingrained in the CCTVs can identify near misses, such as a hand too close to an unguarded blade or a load swaying perilously during overhead transport. This data gets automatically logged, time-stamped, and even categorized for trend analysis.

Over time, these facilities laid down by AI can identify not just isolated risks, but systemic vulnerabilities—areas, shifts, or behaviors that consistently flirt with disaster.

When AI was deployed at a metal fabrication plant in Hong Kong, it detected a pattern of near misses involving workers reaching over active conveyor belts during night shifts. The identification led to a 35% reduction in unsafe hand placements and a 50% drop in repeat near-miss incidents within just three months.

The Internet of Things (IoT) acts as the nervous system of this intelligent safety infrastructure. And when it is combined with the power of AI, advanced AIoT tools like Wearables, smart helmets, and environmental sensors continuously stream data across the facility.

It can be well agreed that IoT, when combined with AI, data turns into the development of context-aware actions.

For example, in a logistics company, a smart weather station can detect extreme environmental conditions like rain and reroute a vehicle part of the transportation process, based on the chances of a landslide in the upcoming delivery trip.

A smart watch can monitor the heart rate and body temperature of workers, alerting supervisors if they show signs of fatigue or stress, critical in environments where mental and physical overloads can have lethal consequences.

The AIoT-based risk matrix treats environmental factors like floor vibrations, humidity, and noise not as separate data points, but as interconnected signals. For example, if an excessive vibration is combined with high noise levels say 85 dB(A), it might indicate malfunctioning machinery, raising the risk of mechanical failure or injury.

By analyzing these variables together in real time, AIoT connects the dots and flags anomalies early, triggering preventive actions before hazards escalate.

One of AI’s most profound contributions is machine learning—the ability to improve with exposure. Unlike static protocols, AI models learn from every new input, refining their risk assessment capabilities over time.

This is especially transformative in multi-site manufacturing environments, where data from one facility can be used to improve safety measures in another. For example, an AI system that learns about a recurring machinery hazard in one plant can proactively adjust safety protocols in all plants using the same machinery.

In this way, AI makes safety not just local, but scalable.

What’s striking to note in 2025 is how AI in workplace safety is not just changing systems, but shifting cultures. Safety is no longer a checklist but a real-time, living process. Workers, when being aware that the environment is actively monitoring and protecting them, become more engaged in their well-being.

Supervisors and EHS teams are backed by intelligent insights, overlooking a shift from enforcers to enablers.

Workplace safety AI is thus not replacing the human element—it is empowering it.

As AI systems evolve, we can expect a deeper integration of natural language processing to allow conversational AI safety tools, digital twins for risk simulations, and augmented reality overlays to train manufacturing site workers.

However, the one thing to note is that the ethical compass must remain central. AI in workplace safety should always prioritize transparency, worker dignity, and explanation ability. The goal isn’t total automation but intelligent collaboration.

Factory floors have always been places of innovation, but their safety frameworks often lag behind their production capabilities. Today, with AI in workplace safety, we are witnessing a long-overdue convergence. Safety is no longer a secondary protocol—it is becoming the first line of productivity.

As Gary Ng, CEO of viAct puts it, “When you embed intelligence into the fabric of the workplace, safety stops being a compliance requirement and starts becoming a competitive advantage.”

This factory reset is not a restart—it’s a reboot. One where data, machines, and humans finally work in harmony. One where safety is no longer just a goal, but a given.

About the Author:

Gary Ng, CEO and Co-Founder of viAct comes with a background of building engineering who turned into AIpreneur with inception of viAct in 2016. He has 10+ years of experience in implementing technological innovations in construction industry. Before viAct, he was the Managing Director of 3D fashiontech EFI Optitex. Also rewarded as the best regional senior executive in NASDAQ listed technology enterprise Stratasys. With his ultimate strength of analytical thinking & strategic decision making, Gary was also the advisory board member for SXSV in his early career. Gary believes in the concept of transferring knowledge from experienced to youngsters and is a renowned academic professional. Currently he is a visiting faculty professional at The Hong Kong Polytechnic University. Gray is also an active public speaker & preacher of AI driven sustainability in workplaces.

Scott Ellyson, CEO of East West Manufacturing, brings decades of global manufacturing and supply chain leadership to the conversation. In this episode, he shares practical insights on scaling operations, navigating complexity, and building resilient manufacturing networks in an increasingly connected world.