Volume 28 | Issue 3

Click here to read the complete illustrated article or continue below to read the text article.

By Chris Lanio, CNC Programmer / CAMMMachinist, Dimensional Innovations

In the world of industrial fabrication, new technologies often emerge quietly— serving niche needs at first—before rapidly rewriting the rules of what’s possible. One such innovation is Composite Additive Manufacturing Machines (CAMM) sometimes referred to as large-scale 3D printing.

Unlike conventional desktop printers that have become common in prototyping, CAMM operates on a much larger stage, combining massive extrusion printing with integrated precision machining. This approach makes it possible to produce components measured in feet or even yards, while maintaining the structural integrity needed for real-world applications.

What sets CAMM apart is its ability to merge scale with accuracy. Whereas desktop systems are limited to small prototypes, CAMM can produce full-scale architectural features, transportation components or large industrial tooling in reinforced polymers.

By combining fillers such as carbon fiber or glass fiber, these parts achieve the strength and stability to withstand heat, stress and long-term use. With fewer than a dozen machines of this size currently in operation across the U.S., the technology remains rare but increasingly sought after in industries that demand complex solutions. What follows is a deeper dive.

A striking example of its potential stands inside Allegiant Stadium in Las Vegas: the Al Davis Memorial Torch, a 90-foot installation honoring the late Raiders owner.

In pursuing this project, the Raiders organization quickly ran into a challenge with the impressive ambition: traditional fabrication methods—such as casting, forming or subtractive machining—would have made the project prohibitively expensive, time-consuming and material-intensive. By turning to CAMM, however, engineers and fabricators were able to produce massive polymer forms that could be machined, assembled and finished into one complete structure.

The result is not only a visually iconic centerpiece of the NFL but also a proof point of how large-format 3D printing can redefine what’s possible in modern fabrication.

Novel materials: To satisfy safety requirements, a fire-suppression additive was incorporated into the polymer. This required custom R&D and validation testing with Purdue University to ensure both mechanical performance and fire safety. The final torch was produced from polycarbonate reinforced with 20% carbon fiber—the same base polymer used in bulletproof glass and aquarium tanks.

Precision alignment: Even aesthetic considerations, such as aligning the carbon fiber stripes consistently throughout the structure, demanded close coordination between design, programming and machining teams.

Functionality shift: The original concept called for an open flame, but safety regulations required a simulated flame instead. Thanks to the flexibility of additive methods, the design pivot was accommodated without redoing months of fabrication work.

All told, the project required roughly 14 months of near-continuous printing and machining, carried out across Dimensional Innovations’ massive facility, operating across two shifts almost around the clock.

As with any frontier technology, large-format additive manufacturing comes with its own set of challenges. Design limitations are often the first hurdle—unlike smaller printers that can rely on support structures for complex overhangs, CAMM works best with closed shapes. Unsupported angles greater than 30 degrees are risky, which means large parts may need to be split, printed separately and then mechanically joined. This makes early collaboration between engineers and fabrication teams essential, ensuring design constraints are accounted for before models are finalized.

Environmental control is another critical factor. Even a trace amount of moisture—more than 0.02% in polycarbonate—can compromise a print. Keeping materials properly dried and fabrication environments tightly sealed is more than just best practice; it’s critical. Beyond that, machine maintenance presents its own challenges. With fewer than a dozen of these large-scale machines in the U.S., servicing is complex, and long idle periods can increase the risk of breakdowns. Keeping a steady workflow helps maintain reliability.

Finally, one of the most common misconceptions is that 3D printing is as simple as “press and done.” In reality, most CAMM projects require extensive post-machining to achieve smooth finishes and precise tolerances. Yet even with this added step, the process offers undeniable advantages: waste is only a fraction of what’s generated in subtractive methods, and overall turnaround times are significantly reduced.

Large-format additive manufacturing is redefining how ambitious ideas move from concept to reality. By combining design freedom with the ability to produce durable, large-scale components, it enables teams to deliver pieces that would be prohibitively expensive—or even impossible—through traditional fabrication. Architects, designers and brands often turn to this technology for one-of-a-kind structures, sculptural elements or custom components that need to both inspire and perform. The process typically unfolds in four key stages:

Engineering & Modeling – A 3D solid model is developed to define the intended form and function.

Programming & Pathing – Specialized software generates the tool paths, balancing cooling times and structural stability.

Printing & Machining – Material is extruded layer by layer, with precision machining often integrated into the same workflow for accuracy.

Finishing & Assembly – Post-processing steps such as trimming, sanding, coating, or joining transform raw prints into final, manufacturable products.

By aligning creative vision with technical expertise at each stage, manufacturers can achieve both artistry and precision, at a scale previously out of reach.

For manufacturers exploring large-format additive manufacturing, success depends on more than just the machine—it requires a thoughtful approach from design through delivery. One of the most important steps is involving fabrication experts early. What looks perfect in CAD may not hold up once unsupported overhangs or cooling stresses are factored in, and machinists or programmers can identify those issues before they become costly mistakes. Environmental control is just as critical. High-heat polymers demand precise humidity and temperature regulation, and even a minor fluctuation can compromise structural integrity.

The right tooling also matters. Reinforcing fillers such as carbon fiber or glass fiber increase durability but are highly abrasive, meaning diamond-coated tools are the only reliable option. Beyond that, it’s important to recognize that printing is only half the journey. Post-processing—machining, finishing and assembly—must be built into project budgets and timelines from the start. Finally, manufacturers should think of large-format 3D printing as a complementary process rather than a universal solution. Its sweet spot lies in producing large, unique parts where traditional methods are inefficient, costly or impractical.

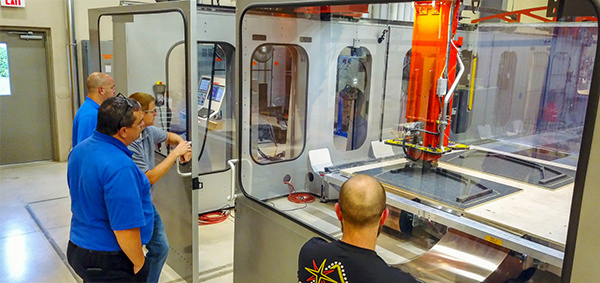

At the heart of DI’s fabrication powerhouse is one of the region’s largest 3D printers, called Large Scale Additive Manufacturing (LSAM) machine. Its impressive build volume of 10 by 20 by 5 feet is equipped with a five-axis router.

Housed in our 200,000-square-foot fabrication facility, the LSAM enables DI to effortlessly shift from conceptual designs to monumental, structurally sound printed installations. From intricate prototypes to massive architectural elements, DI’s 3D printing capabilities showcase the transformation of vision into realty.

Large-scale 3D printing is still in its adolescence, but its potential is enormous. From aerospace to automotive, from architecture to industrial design, the ability to fabricate custom, large-scale, structurally sound parts with minimal waste is rewriting the playbook.

The CAMM is more than just a machine— it’s a bridge between imagination and reality. It allows alignment of creative intent with technical execution at a scale once unimaginable. DI’s work on the Raiders Torch stands as proof: with the right technology, even the boldest visions can be built.

As manufacturers, the challenge is not just adopting new tools, but learning how to think differently about what those tools make possible. CAMM isn’t just another way to fabricate— it’s an entirely new way to imagine.

About the Author:

As CNC Programmer and CAMM Machinist at Dimensional Innovations, Chris Lanio plays a key role in programming large-scale additive manufacturing and CNC projects. Chris is a master from complex 3D toolpaths to multi-axis programming, producing high-tolerance parts for industries ranging from food packaging to aerospace.

Scott Ellyson, CEO of East West Manufacturing, brings decades of global manufacturing and supply chain leadership to the conversation. In this episode, he shares practical insights on scaling operations, navigating complexity, and building resilient manufacturing networks in an increasingly connected world.