Fully automatic wire bending technology injects new vitality into traditional refractory anchor manufacturing.

In today’s competitive manufacturing environment, efficiency, precision, and automation are redefining industry standards. Fastenmetal LTD is proud to announce the integration of fully automatic CNC wire bending machines into its refractory anchor production lines. A move that modernizes traditional processes and injects new vitality into this essential industrial sector.

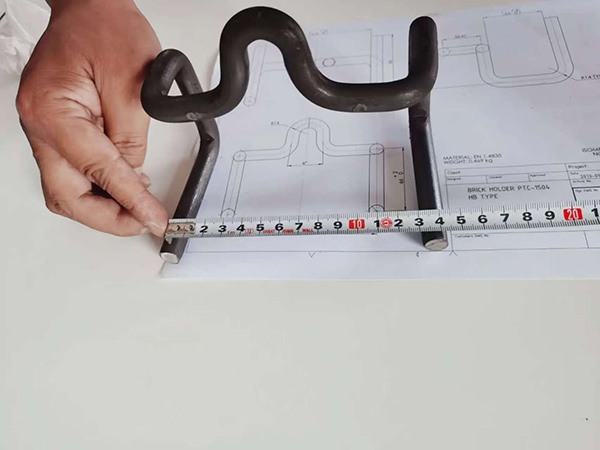

Anchors for refractory are main components used to secure linings in high temperature environments such as cement kilns, steel furnaces, petrochemical reactors, and power plants. Traditionally, these anchors were produced using manual or semi-automatic bending methods, limiting production speed, consistency, and overall precision. By introducing fully automatic wire bending machines, Fastenmetal is transforming production, increasing efficiency, and setting a new benchmark in quality control.

The newly introduced machines employ advanced CNC control systems to achieve one-time precision forming. From straightening and feeding wire to bending, shaping, and cutting, the process is fully automated in a single operation.

Unlike manual methods that rely heavily on operator skill and repeated handling, CNC forming ensures:

One time forming also minimizes stress points caused by repeated bends, increasing the durability and performance of refractory anchors under extreme operating conditions.

Automation provides an immediate boost to production efficiency. With fully automatic CNC machines, output per shift has increased significantly, while dependence on skilled manual labor has decreased.

By automating repetitive bending tasks, production teams can focus on quality control, process improvement, and engineering customization. This shift not only improves throughput but also enhances workplace safety by reducing repetitive strain and manual handling risks.

In an era of skilled labor shortages, automation provides a sustainable solution, allowing Fastenmetal to scale production without sacrificing quality or delivery reliability.

Modern refractory applications demand custom anchor geometries tailored to specific lining materials, temperatures, and mechanical loads. CNC wire bending systems allow Fastenmetal to respond efficiently to these requirements.

The machines can produce a wide range of anchor types, including:

Multiple materials can be processed, including carbon steel, stainless steel, heat resistant alloys, and specialty grades. Design changes that previously required tooling adjustments can now be implemented digitally, dramatically reducing lead times for custom orders.

The refractory industry has often been slow to adopt new technologies. Fastenmetal’s deployment of fully automatic CNC wire bending machines proves that even traditional manufacturing sectors can benefit from automation and digital transformation.

“This is more than just new equipment—it’s a strategic investment in the future,” said a company representative. “By combining automation with our deep expertise in refractory anchors, we’re creating a system that is faster, more flexible, and better aligned with evolving customer needs.”

About Fastenmetal LTD

Fastenmetal LTD specializes in industrial fasteners and anchoring solutions, including refractory anchors for high temperature applications. Serving global clients across cement, steel, petrochemical, energy, and power industries, the company emphasizes precision manufacturing, material expertise, and customized solutions.

Through ongoing investment in advanced machinery, automation, and engineering, Fastenmetal delivers reliable products, consistent quality, and long-term value to its customers.

Scott Ellyson, CEO of East West Manufacturing, brings decades of global manufacturing and supply chain leadership to the conversation. In this episode, he shares practical insights on scaling operations, navigating complexity, and building resilient manufacturing networks in an increasingly connected world.