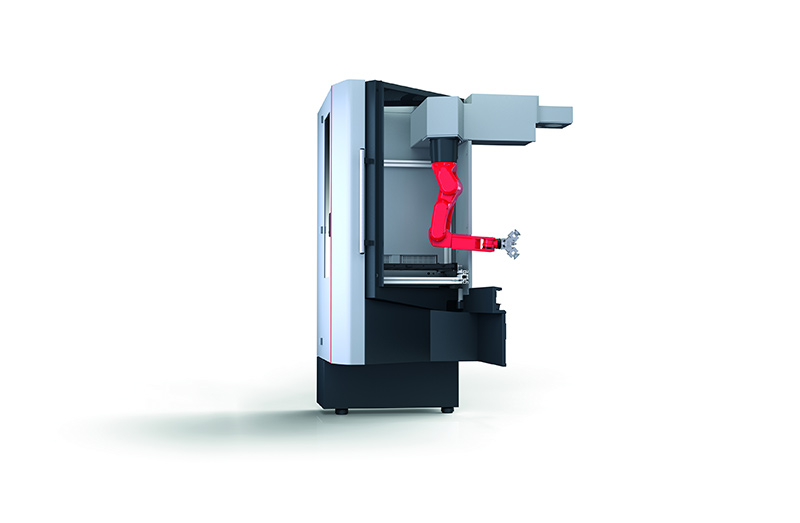

In the past, manufacturing cells with a supply of workpieces for one shift have often been 2-part systems that required a lot of time and effort to integrate into the process chain. Schwäbische Werkzeugmaschinen GmbH (SW) has released two new plug-and-play-capable manufacturing cells: The systems consist of the proven machine tool BA 222 or BA W02-22 together with a newly developed loading module with integrated 6-axis robot and vertical pallet storage for blanks and finished parts. The module enables loading and unloading of the machining center in parallel to machining time and is completely flanged onto the basic machine in the SW plant.

Schwäbische Werkzeugmaschinen GmbH (SW) with headquarters in Schramberg-Waldmössingen, Germany is an international supplier of solutions for sophisticated metal working production systems customized for specific workpieces. One of its core competences is high-performance multi-spindle machining centers, with more than 3000 installed at customer sites worldwide in many different sectors of industry. To be able to offer the right solution for any application, the company also continuously develops new machining possibilities and optimizes existing techniques in its own technology center. SW also offers a comprehensive portfolio of consultation and services. Currently staffed with about 700 employees worldwide, SW posted sales of €305 million in 2017.

Schwäbische Werkzeugmaschinen GmbH (SW) has released two new plug-and-play-capable manufacturing cells: The systems consist of the two-spindle BA 222 or BA W02-22 together with a newly developed loading module with integrated 6-axis robot and vertical pallet storage for blanks and finished parts.

Source: SW

For especially cramped conditions the manufacturing cell is available in a version with the loading module specially designed as a corner solution with transverse material flow. This variant features a special arc-shaped robot loading door and allows for nearly unrestricted access for all setup tasks at the loading station.

Source: SW

Wolfgang Armleder, Director of Development at SW.

Source: SW

Scott Ellyson, CEO of East West Manufacturing, brings decades of global manufacturing and supply chain leadership to the conversation. In this episode, he shares practical insights on scaling operations, navigating complexity, and building resilient manufacturing networks in an increasingly connected world.