Effective production: Embedded AI finds faults in engines, shafts and gearboxes in ships, cars, trucks and airplanes.

Late detected faults during EOL (End of Line) testing can be expensive. A car engine whose defect is only detected after it has been installed in the vehicle can easily cause costs of five to ten thousand euros for reassembly, repair and delivery delays. However, it is not only drives, shafts, transmissions, brakes and overall testing in the automotive segment that are affected, but also in shipbuilding, truck and aircraft construction and many other industries. If manufacturers use an embedded AI ultrasonic sensor system, they can detect significantly more faults at an early stage and counteract the problem.

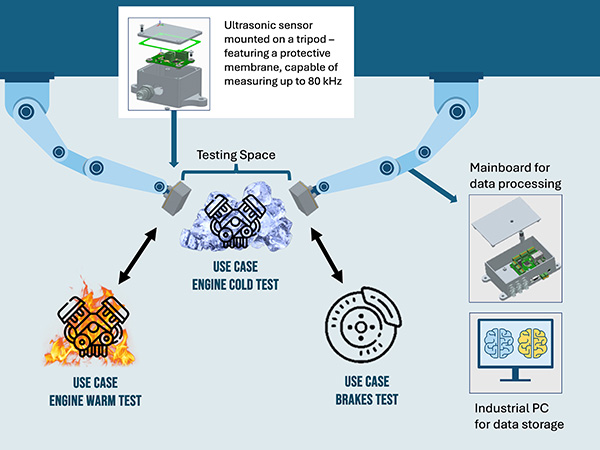

During EOL testing of subcomponents in the automotive industry, various tests are carried out to prevent a faulty component from being installed in the vehicle. For example, tests are carried out for production errors, completeness and tight fit of screw connections, correct adjustment of chains, gears, seals and much more.

“If the fault only becomes apparent after installation – or even worse: at the customer’s premises – this results in high costs that need to be avoided. For example, it is estimated that removing a car engine takes 460 minutes, and if you add material and consequential costs (e.g. due to a delay in delivery), the total cost can quickly add up to several thousand euros,” explains Viacheslav Gromov, Managing Director of AI specialist AITAD.

Classic EOL test procedures already use sensors, such as temperature, angle, vibration and pressure sensors, for cold (externally moved), hot (self-moving) and performance tests in order to detect deviations from the ideal state of the respective component. Acoustic sensors are also used to search for deviating spectrum weightings in the data. Finally, after final assembly in the end product, there is often a person who „hears“ the component‘s failures in test operation, i.e., recognizes from certain noise patterns whether the component is OK or not. Despite these measures, faulty parts often remain undetected or are discovered far too late.

In order for a human listener to recognize errors in the sound pattern of an engine for example, many years of experience are usually required. This experience is in danger of disappearing due to demographic change. A scenario that is exacerbated by the shortage of skilled workers. The pressure to find new, more precise and comparable solutions for EOL parts testing is therefore high for both personnel and financial reasons.

This is where the development of embedded AI sensors comes into play. Such sensors use AI (artificial intelligence) to evaluate sensor data. As the AI and sensor are fused together on one circuit board, the data can not only be evaluated in real time (which is a great advantage for test cycles that sometimes take seconds), but also in much greater depth.

For example, an ultrasonic sensor that records signals at a sampling rate of hundreds of kilohertz and a vertical resolution of 32 bits generates several terabytes of raw data per day, even in small quantities – a volume of data that could not practicably be transmitted via conventional network connections and which also poses an ever greater challenge in terms of plant infrastructure and clocking.

Embedded AI, however, can “view” the raw sensor data byte by byte and thus make things visible that were previously invisible. After evaluation, the data is deleted and the embedded AI module only passes on the information obtained from it. This also makes these systems very secure against data manipulation or theft of sensitive production know-how data.

The special capabilities of embedded AI can be used for EOL testing and promise a much higher fault detection rate than would be achievable with conventional EOL test benches using only “classic” sensors or acoustics. The test tracks do not have to be replaced for this but can be retrofitted with embedded AI modules at low cost.

“In the case outlined above, a high-resolution ultrasonic sensor solution is ideal for detecting faults at an early stage and keeping the costs caused by faulty parts as low as possible. As this is a data-driven development, various development steps are required before a functional “EOL early warning system” can be used,” continues Gromov.

To do this, data must first be collected at the various test stations using acquisition hardware equipped with different types of sensors, correlated with the faults found by conventional means and transferred to a database. Datascience examines this data and develops a ML model (machine learning model) on this basis, which is trained to detect anomalies in the first step, but can later be adjusted more finely (error type and localization) through classification. At the same time, the final sensor hardware, on which the AI model is installed, is being further developed.

The error detection rate of such a system is very high, as the AI analyzes complex patterns that would not be visible to humans. „We were able to achieve a detection rate of over 95% early on in the EOL testing chain with a specially developed ultrasonic sensor solution at an automotive manufacturer, which in turn contributed to high savings,“ says Gromov, reporting concrete successes.

Last but not least, the AI can also acquire the empirical knowledge of a human listener and objectify it, which means that faulty parts – e.g. already installed in the end product – can be selected even better. This solution is also very helpful for product and delivery part changes, as modified products often still have high error rates. By collecting data quickly and updating the AI model, it is possible to react much faster at the start of production.

An AI-based, high-resolution ultrasonic sensor system for EOL testing is suitable for many industries: From automotive, truck and mechanical engineering to ship and aircraft construction, the early selection of faulty parts can save considerable costs. Such solutions are likely to be particularly interesting for shipbuilding and aircraft construction, as engines in these industries are especially expensive and are often almost impossible to remove after installation.

The system can minimize risks and damage, particularly in the event of supplier part changes, new production start-ups or assembly changes. „Depending on the use case, an embedded AI ultrasonic sensor system can be developed, trained and integrated for as little as around 100,000 euros. Costs that quickly pay for themselves,“ says Gromov, citing the development costs for such a system as another advantage.

On AITAD

AITAD is a German embedded AI provider. The company focuses on the development, testing and series production of AI electronic systems, particularly in connection with machine learning in an industrial context (especially system components).

As a development partner, AITAD handles the entire process from data collection to development and delivery of the system components. As a result, innovative adaptations are made to the product without the need for expertise and only a few resources on the part of the customer. The focus is on future-oriented, disruptive, innovative adaptations with the greatest possible impact on structures and product strategies.

AITAD specializes in preventive/predictive maintenance, user interaction and functional innovations. AITAD takes a different approach to many manufacturers: instead of a ready-made AI solution, an individual system is developed for each customer. In the first step, the company examines how customer products benefit from the use of AI, presents the advantages and possibilities, develops the system at all levels, builds a prototype of the new system in-house thanks to a prototyping EMS line based on collected data and is always on hand for series production and system maintenance. AITAD acts as an interdisciplinary full-stack provider in the fields of data science, mechanical engineering and embedded hardware and software. AITAD also conducts internal and external research into numerous algorithmic and semiconductor fundamentals of AI technology.

In 2023, AITAD received the embedded award in the AI category, the Top100 innovation award for medium-sized companies and was named AI Champion Baden-Württemberg.

Further information www.aitad.de.

Scott Ellyson, CEO of East West Manufacturing, brings decades of global manufacturing and supply chain leadership to the conversation. In this episode, he shares practical insights on scaling operations, navigating complexity, and building resilient manufacturing networks in an increasingly connected world.