Bill Murray, senior researcher and advisor, Leading Edge Forum, discusses how manufacturing organizations can achieve antifragility.

The current pandemic has been the biggest catalyst for digital transformation in the last five years and has tested the agility of businesses like no other in modern memory. What it has also shown, though, is how brittle and fragile many organizations are.

Weaknesses in supply chains and brittle operational processes have been made public. “Antifragility,” rather than agility, is the new watch word in business resilience.

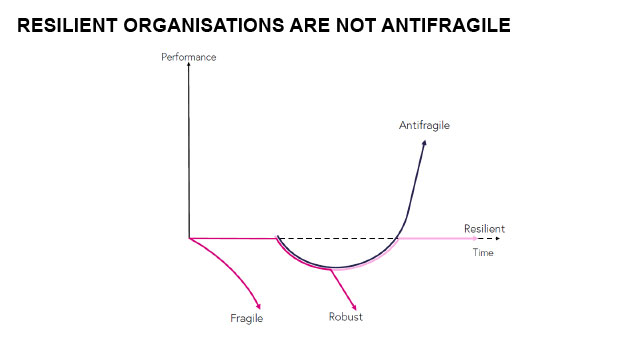

Resilient organizations are not antifragile.

Depending upon how resistant a business is against future shocks, it can sit in one of four categories: Fragile, Brittle, Resilient or Antifragile.

While resilience for manufacturers is the ability to keep generating economic profit through cyclical and structural changes in supply and demand, antifragility is the additional ability to use shocks and volatility to grow revenue and profit, even enter new markets or cause disruption in existing ones. It’s what manufacturing businesses should be aiming for.

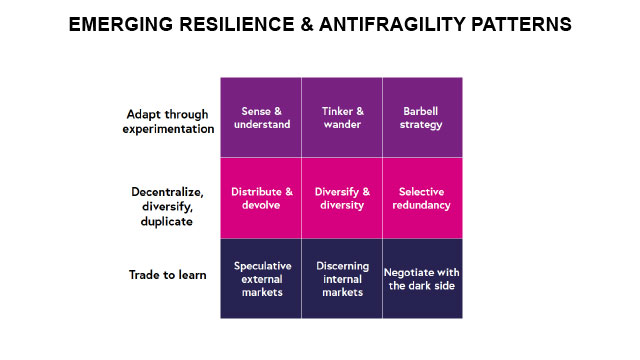

Emerging resilience and antifragility patterns.

The challenge for manufacturing companies is that they are more and more intertwined with their ecosystems, and it’s this fragmentation of the operating model in service of efficiency that brings risk through shocks.

To achieve antifragility, manufacturing organizations should adopt the following framework:

It is important to note that although the three stages are represented sequentially, the success of this model will require businesses to be agile, breaking programs down into manageable pieces. Failing fast is a must, and feedback loops to allow continuous improvement are critical.

We will feel aftershocks after almost any shock. It may also be the case that we create our own aftershocks through the transformation of our organizations. Be careful and have your seismic sensors in place, capturing the data from your test points and responding appropriately.

Once a shock is over, smart manufacturing businesses will look back and consider what worked and what didn’t, in order to prepare for future disruptions around the corner. Aside from rethinking boardroom priorities and the value of efficiency over capacity and quality over availability, some of the emergency measures brought in may benefit the business in the future.

Bill Murray

Bill Murray is a senior researcher and advisor for Leading Edge Forum with a wealth of experience in developing digital and business technology strategies, business cases and change programs involving technology disruptions such as consumerization, analytics and cloud-based services. Most recently, Bill has been helping clients develop IoT enabled business propositions and services in Connected Health, Connected Insurance, FMCG and supply chains, and advising on IoT platforms.

Scott Ellyson, CEO of East West Manufacturing, brings decades of global manufacturing and supply chain leadership to the conversation. In this episode, he shares practical insights on scaling operations, navigating complexity, and building resilient manufacturing networks in an increasingly connected world.