Bison® & OBAR partner to design vapor intrusion mitigation blowers.

Vapor intrusion (VI) occurs when there is a migration of vapor- forming chemicals from any subsurface source into an overlying building. These vapors may accumulate in dwellings or occupied buildings to levels that may pose safety hazards and acute health effects.

The most common method used in VI mitigation is sub-slab depressurization. The concept involves creating a vacuum under the slab, then drawing the gas into the system where it can be discharged to a safe location. The system consists of a network of pipes that penetrate the slab into the soil. These pipes are connected to a specialized blower that discharges the collected gas to a safe location.

In 2008, the specialized blowers used for this demanding application were very expensive, large, heavy, awkward and inefficient. Environmental contractors, facility managers and site developers needed a better solution to mitigate VI.

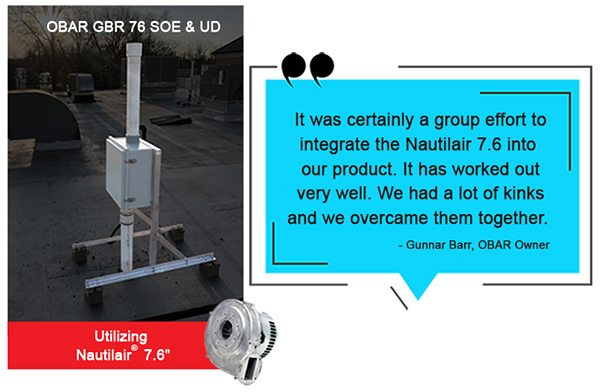

Fifteen years ago, Gunnar Barr – owner of OBAR Systems, Inc. (OBAR) – designed and manufactured the GBR 76 SOE. This product was the first in the industry to meet the safety standards, the vacuum/volume capacity requirements as well as feature a compact design, longer life and easy installation.

The GBR 76 SOE integrated the Nautilair® 7.6″ Combustion Blower by Bison. Gunnar’s reasons for collaborating with Bison were four-fold:

OBAR and Bison engineers collaborated extensively to customize and integrate the Nautilair 7.6″ blower into the first version of the GBR 76 SOE.

The customized version of the Nautilair 7.6″ included:

“It was certainly a group effort to integrate the Nautilair 7.6 into our product. It has worked out very well. We had a lot of kinks and we overcame them together,” said Gunnar Barr, OBAR Owner.

After the launch of GBR 76 SOE, it became evident that OBAR had reached its goal.The company developed the most cost-effective VI mitigation solution that was the least expensive and the easiest product on the market to install. Plus, this product was helping its customers meet very strict EPA, state and local regulations.

Years later OBAR learned about the robustness of the product. Considering the demanding application of exhausting volatile organic compounds including trichloroethylene, benzene, perchloroethylene and methane, away from indoor spaces and discharging them into safe locations, it is notable that many units have exceeded their life expectancy of 4.5 years up to 12- plus years. That is nearly three times the expected life of the product.

The OBAR-Bison collaboration has progressed over the last 15 years, leading the way to customization of additional Nautilair blower models to meet OBAR’s growing product development needs.

Programming, capacitor and remote potentiometer customization to the Nautilair 7.6″ and 8.9″ blowers have all made significant impacts on OBAR’s continuous improvement efforts of the GBR 76 SOE as well as product line extensions – GBR 76 UD and GBR 89 HA.

OBAR recently prototyped a new product, GBR 123, which specifies the Nautilair 12.3″ High Energy Combustion Blower. The GBR 123 fills a small void in the company’s current product line because it can handle VI mitigation for larger buildings (up to 1M sq. ft.) with homogeneous soil profiles.

The GBR 123 value proposition is that one blower can be spread out over a very large area with multiple extraction points, providing significant savings for clients in terms of time, dollars and energy.

While the GBR 123 hasn’t been released to the mass market yet, early adopters’ tests report encouraging data. Buyers interested in this product can email Matt Troeller.

Units Sold Have Doubled Every Year Since 2019

OBAR is experiencing significant growth, doubling its units sold every year since 2019. There are several key drivers supporting this growth:

“The relationship between OBAR and Bison has been excellent. There’s a lot of benefit to working with a company like Bison on the technical side. Bison engineers can turn less technical information from the field into something helpful and actionable,” said Matt Troeller, OBAR Wholesale Manager.

To learn more about OBAR’s VI mitigation expertise and its products, visit their website found here.

Scott Ellyson, CEO of East West Manufacturing, brings decades of global manufacturing and supply chain leadership to the conversation. In this episode, he shares practical insights on scaling operations, navigating complexity, and building resilient manufacturing networks in an increasingly connected world.