Volume 26 | Issue 1

Click here to read the complete illustrated article or continue below to read the text article.

The future is electric for more than passenger cars: the Lion Electric Company, a leading North American manufacturer of all-electric medium- and heavy-duty urban trucks and buses, delivered 199 vehicles in Q2 2023, a 90% increase compared to 105 delivered in the same period in 2022.

While Tesla deserves credit for accelerating the transition from gas-powered cars to ZEVs (Zero Emission Vehicles), Canada-based Lion is roaring ahead to do the same in the truck and bus sector. The Saint-Jérôme, Quebec company is unique in that unlike other electric urban truck and bus makers, Lion isn’t retrofitting fossil-fueled vehicles, but rather building its electric platform from the ground up. Lion designs, manufactures, and assembles most of its vehicle components, including chassis, battery packs, cabin, and powertrain.

Moreover, as Dominik Beckman, VP of Marketing and Communications, points out, “Lion is doing more than making electric buses and trucks; we’re providing an entire sustainable ecosystem to support the transition to electrification. That includes not only providing a charging infrastructure for zero-emission electric fleets, but also telematics and management software, technician and driver training, maintenance support, and capital financing.” Lion is also adding to what it calls “Experience Centers” throughout the U.S. and Canada to provide after-sales service and parts.

An equally important distinction is that Lion does not depend on a third-party dealer network. “We work directly with fleet owners to help them successfully transition to electrification, which includes building the infrastructure as well as providing the vehicles.”

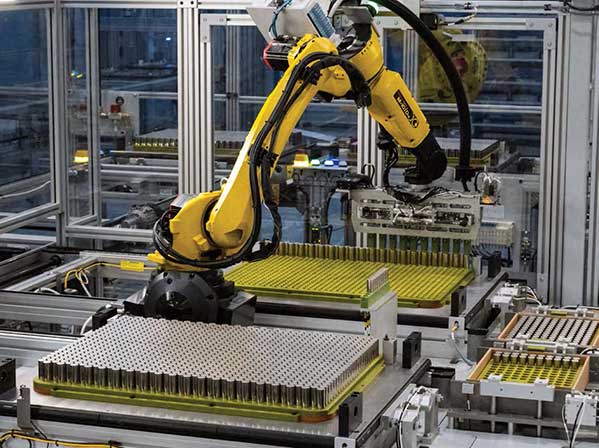

An additional Lion advantage is that it is a vertically integrated manufacturer — just this past April the company officially inaugurated its new 175,000 square foot facility in Mirabel, Quebec to produce lithium-ion battery packs for its medium- and heavy-duty vehicles made it its Saint-Jérôme and Joliet, Ill. plants. The new battery pack assembly line, the first of its kind in Canada, is planned to reach production capacity of 1.7 gigawatt hours by the end of 2023, with a targeted annual production capacity of 5 gigawatts. The expectation is this can allow Lion to produce a mix of about 14,000 vehicles a year.

The company currently employs roughly 1400 people. “Our manufacturing is highly automated, but like everyone else we are in need of a range of technical and professional skills sets,” Beckman says. But unlike other manufacturers, Lion isn’t experiencing sizable talent gaps, due perhaps in part because of its reputation for innovation as well as its commitment to green technologies.

Since entering production of electric buses in 2016, Lion has delivered more than 1,400 all-electric medium- and heavy-duty vehicles in North America, that have collectively driven more than 14 million miles. “These vehicles are purpose-built for electric drivetrains,” Beckman emphasizes. “As an example of why that’s an advantage, our electric school buses are specifically designed to provide wider aisles in the same size chassis of a fossil-fueled bus.

In addition to providing the driver with better visibility to what’s behind them, this also improves safety in case there’s ever a need for passengers to exit the bus quickly. An additional safety feature, of course, is that children aren’t exposed to exhaust fumes on a bus with no emissions.” In addition to school buses, Lion also makes an all-electric midi/minibus for the paratransit market that convey an up to 150- mile range and a 24-passenger capacity with easy accessibility and enhanced security. Lion’s all-electric class 5 through 8 commercial urban trucks combine power, comfort, and modern technology. Most recently, Lion premiered its first ever Lion5, with payload configurations ranging from 19,500 lbs. through 26,000 lbs. Gross Vehicle Weight Rating (GVWR), and a driving range of up to 200 miles perfect for last mile delivery vehicles, slated for full production later this year.

“A key advantage to the Lion5 is the ability to carry more weight than is typical for electric vehicles in its max GVW class,” Beckman says. “With the higher payload capacity and ease of drivability, the Lion5, combined with safety features such as stairstep entry/exit, superior visibility and quiet operation, fleet owners in today’s tight job market gain access to larger pool of qualified and interested operators.”

Beckman points out that, ZEVs are perfect for last mile delivery, local bus transportation, refuse collection, and other applications where there are defined urban routes confined to one-day duty cycles. The vehicle gets charged overnight, needs only travel within a 100- or 200-mile distance, and then comes back to its depot to get recharged and ready for the next day’s operation.”

In addition to the vital role ZEVs play to help the U.S. and Canada reach their clean energy and net-zero targets by 2050 (medium- and heavy-duty vehicles account for nearly 40% of greenhouse gas emissions in the transportation sector), Lion all-electric vehicles provide users with a variety of economic as well as social advantages.

“We do a great deal of customer education,” Beckman says. “There are still a lot of myths out there about ZEVs that at least do not apply to Lion, such as that the batteries don’t work in cold weather. They do, which is why we developed our own BMS (battery management system) and BTMS (battery thermal management system) to control and access the full capability of our batteries, minimizing range variability in extreme weather conditions.”

He adds that fleet owners often aren’t sure of the financial advantages. “There’s no engine and there’s less mechanical complexity with an electric vehicle, so there’s less maintenance in terms not only of eliminating oil changes but also there’s fewer parts to replace. On average, electric vehicle maintenance is 60% less expensive to maintain than buses or trucks that use diesel. They are also cheaper to drive, with energy costs reduced by 80%. In addition, there are also government subsidies and incentives to promote fleet electrification. Most use cases show a payback within seven years by transitioning to electric vehicles.”

Lion is adding to its school bus lineup with the LionD (80+ passenger capacity) heading into production and is expanding into the Class 8 tractor truck segment as the company moves forward transforming transportation sectors with all-electric zero emission solutions. “It’s a growing market. We’re focused on North America, but there is certainly a lot of opportunity all around the world,” Beckman says.

For electric buses and trucks, turning on the electric seems like a bright idea.

Scott Ellyson, CEO of East West Manufacturing, brings decades of global manufacturing and supply chain leadership to the conversation. In this episode, he shares practical insights on scaling operations, navigating complexity, and building resilient manufacturing networks in an increasingly connected world.