Why having a cleanroom is important in the medical manufacturing industry.

The medical industry needs supplies devoid of harmful pathogens. Medical devices, such as retractors, urinary catheters, face masks for oxygen administration, and single-use anoscopes, should provide care without adding risks to patients and other users. Hence, it’s essential to have a cleanroom in the medical manufacturing industry.

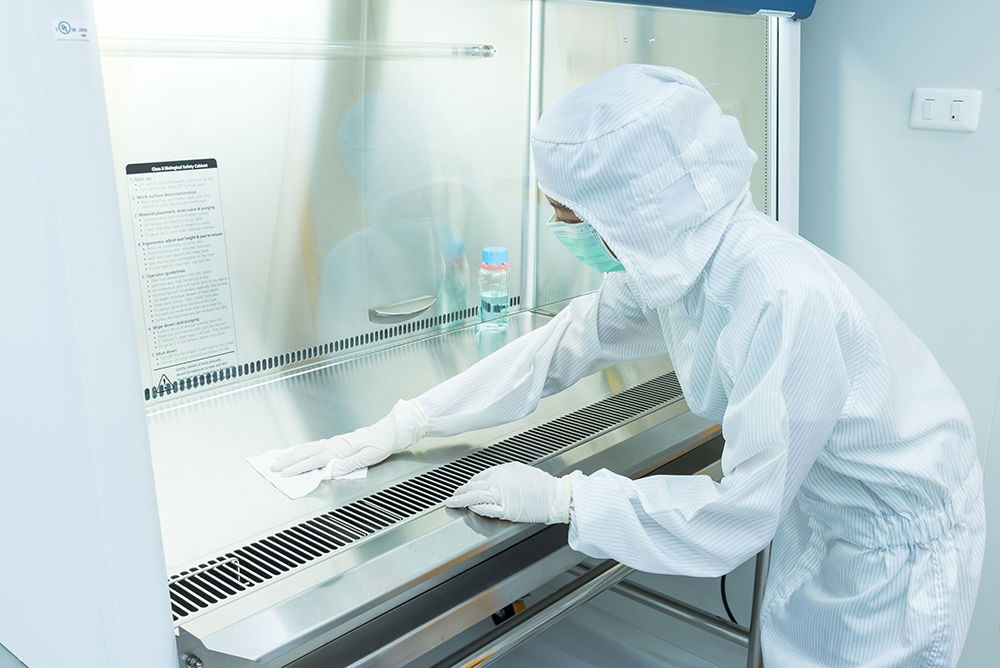

A cleanroom, also referred to as a sterile environment, is a room typically used as part of advanced manufacturing or scientific research. Professionals in the medical and scientific industries use this room for different purposes, such as the production of pharmaceuticals and disposable medical devices.

This germ-free environment helps eliminate contamination from hazardous chemicals, biological waste, and hazardous equipment. Moreover, the cleanroom aims to eliminate and prevent the transfer of disease and infections to people working in the area, while reducing the risks of airborne contaminants.

A cleanroom tends to have no windows and other entryways, aside from doors, to allow air in or out of the premises. This space tends to be in isolated facilities to reduce potential risks of infectious pathogens from entering these spaces.

The different pieces of equipment used in a cleanroom help monitor and control the area, particularly the devices and people inside the space. Partitions exist in this distinct yet isolated location to help reduce potential contamination risks significantly.

Medical manufacturing institutions should pay attention to the importance of having a cleanroom in their properties. Acquiring this space from a reliable cleanroom manufacturing firm may help improve the efficacy of producing sterile equipment for workers in other medical organizations to use.

A high risk of potential microbiological contamination may exist if the production of disposable and non-disposable devices isn’t done in a controlled environment. Failure to address this issue may result in delivering contaminated products, opening doors for infections and other illnesses.

Understanding the importance of a cleanroom helps ensure that the manufacturing of medical items is devoid of contaminants. Note that a cleanroom tends to possess the following elements:

Certified companies that create cleanrooms follow strict guidelines and comprehensive regulations from certain authorities. In turn, the development and use of these controlled facilities can maintain cleanliness throughout each medical device’s manufacturing process.

Setting and enforcing these strict guidelines across various industries, including the medical manufacturing sector, is the International Organization for Standardization (ISO). Certified cleanroom developers follow strict ISO protocols to ensure safety in developing cleanrooms for different medical device manufacturing companies.

Some of these standards may include the following:

Cleanrooms may also find their cleanliness grades by looking at their ISO specifications, which are:

Hence, medical manufacturing organizations should look into cleanroom providers that can provide ISO 5 standard spaces. Companies in this sector may also consider searching for other providers that can only provide ISO 8 decontamination spaces.

The existence of cleanrooms might be more important now than before. Medical manufacturers remain open as the COVID-19 virus continues to spread through international regions. Without the aid of a sterile environment, the production of medical devices might become compromised because of this infectious disease.

Cleanroom developers also note this dire need and follow strict protocols in the manufacturing of these clean environments. Workers create these sterile spaces by following certain guidelines, such as:

Moreover, the cleanroom manufacturers and installers may use personal protective equipment (PPE) to significantly reduce the risks of contaminating the objects in the space.

Perhaps, it’s with the dawn of the 21st century why cleanrooms now have additional precautions to reduce contamination and infection risks. For example, heating, ventilation, and air conditioning (HVAC) systems with high-efficiency particulate air (HEPA) filter help remove airborne contaminants that might exist in the space.

Manufacturing companies may now also use the Internet to their advantage during the development process. Administrators can regulate production procedures through remote monitoring, regardless of their current location, as long as they have a decently-fast and stable Internet connection.

Moreover, some machines may no longer require human intervention to manufacture cleanroom wall systems to reduce contamination threats and human errors. Additionally, modern developers may also use both augmented reality (AR) and spherical video technologies to open doors within workplaces, further reducing potential risks of infections.

The manufacturing and installation of cleanrooms need professionally-trained staff for these tasks. Medical manufacturing firms need to hire cleanroom providers with expert workers to ensure cleanliness during development and installation procedures.

These professionals tend to observe guidelines and rules, such as:

Companies in the medical manufacturing industry need cleanrooms to ensure the safe production, delivery, and use of disposable and non-disposable medical devices. Reliable cleanroom manufacturers aim to supply those needs with sterile spaces and by following strict protocols and regulated ISO standards. These developers may also use the latest technologies and trained staff’s expertise during the production process for medical manufacturers to obtain peace of mind.

Glenn Cook

Glenn Cook shares his knowledge on business by publishing informative content on his blog and submitting guest posts to other websites. Glenn has always been fascinated with the business industry, and have spent years in learning the ins and out of the field.

Scott Ellyson, CEO of East West Manufacturing, brings decades of global manufacturing and supply chain leadership to the conversation. In this episode, he shares practical insights on scaling operations, navigating complexity, and building resilient manufacturing networks in an increasingly connected world.