BSLBATT delivers over 200 lithium batteries to customers of a large industrial battery distributor.

BSLBATT Battery has announced the completion of a huge deal with a major industrial forklift battery distributor. With its BSLBATT® modular technology, BSLBATT is powering material handling equipment for new centers spanning over 950,000 square feet. The company has ordered more than 205 counterbalance forklifts and Narrow Aisle Forklifts batteries since last year. In the long run, only one lithium-ion battery is required per device, compared to the usual two, if not three, lead-acid batteries. In addition to requiring a significant portion of the area to be used for lead-acid battery storage, this route would likely require 410-615 lead-acid batteries. The decision to choose a BSLBATT electric forklift lithium battery eliminated a lot of battery, storage and maintenance.

While at the LOGIMAT trade show this year, a representative from the company stopped by BSLBATT booth and shared greater than expect results from the implementation. It was stated that due to energy efficiencies of the new lithium battery systems; they had achieved more electrical savings than originally planned! The new facility had implemented several new efficiency systems, like the lithium forklift batteries, which overall had saved so much electricity they were not using enough power to justify the grid installed. The usage would not pay for the grid and created a “problem”. Of course, this “problem” would be quickly resolved by having other companies locate to the new industrial zone and allow utilization of the new power grid. Having this “problem” was beneficial and something which they hope to duplicate in the future.

BSLBATT® forklift truck lithium batteries provide numerous advantages over the traditional lead acid. Some of the major benefits of these systems include: needing one battery per piece of equipment, maintenance free – no watering and no equalizing needed, saving space with no need for a charging room, providing higher equipment performance, no need to swap batteries and reducing the environmental impact.

If your company is considering the purchase of a forklift or a fleet of forklifts, you have several decisions to make, including capacity, application fit, vehicle dimensions and lift. But arguably, one of the biggest decisions you will have to make is how to power the forklift – in other words, gas-powered or electric? And if you pick an electric forklift – what technology will your forklift batteries use?

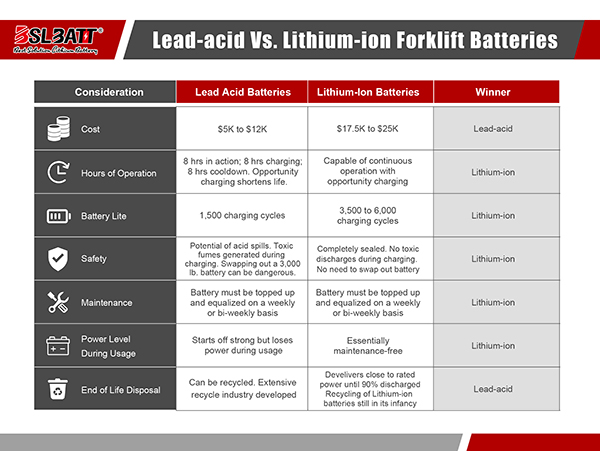

Please refer to the chart below to help you choose the right energy source!

Yes, it is possible to convert your forklift fleet from Lead-acid to Li-ion batteries. The biggest consideration is weight. Most counterbalanced forklifts include the weight of the battery as a parameter for determining load capacity. With a lighter-weight Li-ion battery it will be necessary to add counterweights to maintain the nameplate capacity of the forklift or change the specified lifting capacity to accommodate the lighter Li-ion battery.

Another consideration is culture change. To get the most out of a Li-ion battery, operators need to be trained to rigorously employ opportunity charging. Whenever the forklift is going to be idled for a significant amount of time, remember to plug it in! BSLBATT also provides complete Battery & Charger Maintenance Services. Lastly, provisions need to be made for end-of-life disposal. Currently, there is a well-developed recycling industry for lead-acid batteries. Not so much for Li-ion batteries, although that is changing.

Most fleet operators have noticed a significant improvement in productivity by making the switch from Lead-acid to Li-ion batteries. BSLBATT can help your company with all aspects of employing Li-ion-powered forklifts battery. We stock the full line of Li-ion forklifts battery from Hyster-Yale, Crown, Toyota, Manitou, Clark, Raymond, Combilift, Jungheinrich, Doosan, Linde, Nissan, Hyundai, Caterpillar, JCB, Bobcat, KION group, UNICARRIERS, KOMATSU, HELI, HANGCHA, BYD and Mitsubishi. And, if you’re making the switch from lead-acid to Li-ion batteries for your existing fleet of forklifts, we have availability of a large range of Li-ion batteries to fit almost any material handling need. Additionally, we offer training for handling lead-acid batteries–if you’re sticking with the tried and true–or on proper handling of Li-ion batteries. We also offer training for your staff if you’re making the switch from lead-acid to Li-ion. Interested in Upgrading Your Fleet?

It’s time to reduce labor costs and increase operational efficiency!

Scott Ellyson, CEO of East West Manufacturing, brings decades of global manufacturing and supply chain leadership to the conversation. In this episode, he shares practical insights on scaling operations, navigating complexity, and building resilient manufacturing networks in an increasingly connected world.