Every industry stands to gain from widespread adoption of integrated computational modeling. Energy, in particular, could make a major leap.

By Jiadong Gong

Novel materials are at the heart of innovation in many critical industries. Space exploration, defense and energy – to name just a few – are all reliant on the creation of new materials with properties heretofore unseen. The exciting thing about materials engineering is that many of the alloys and polymers that will shape the future are possible now and are just waiting to be unlocked.

With the emergence of new digital tools and the recent proliferation of artificial intelligence and machine learning, it appears that 2024 may be the year that more companies get the keys to that brighter future.

Digital modeling has been a part of materials science and engineering for many decades now.

Early in its history, engineers would design materials by applying one of several different methods using models that predicted a material’s structure and various properties. Their work was certainly faster and more efficient than the trial-and-error approach that had dominated the field for most of its history, but it was hampered by how disconnected these efforts were.

It wasn’t until the introduction of integrated computational materials engineering in 2008 that the potential of this technology was realized. The key was that first word, “integrated,” which meant that those once-discreet models and methods were now applied in concert, improving the design process and driving down development time.

Materials engineering now finds itself on the precipice of another paradigm shift that will be shaped by two recent developments in digital modeling.

First is the application of machine learning and artificial intelligence in the ICME process. While materials engineers are not yet ceding their jobs to AI, the emergent technology has been used in an assisting role to speed up and simplify what has long been a painstaking job.

These technologies have already helped in the development of new alloys for rocket nozzles, as well as the creation of materials for next generation turbines and a high-strength ceramic capable of shape memory. Machine learning and AI have also allowed engineers unaccustomed to materials design to create a new high-strength aluminum alloy.

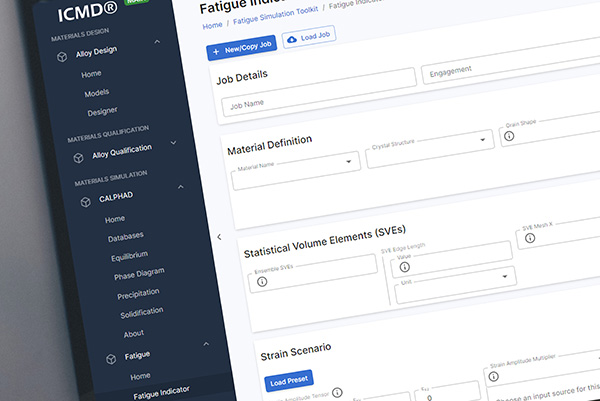

The second advancement comes with the expansion of digital tools that further democratize what has been a highly specialized undertaking. The industry has been moving in this direction for some time, advanced by products like Ansys Granta MI, which helps with materials data management, and Siemens NX, which uses digital twin technology to speed up the design process. In 2023, QuesTek helped initiate the next natural step in this evolution by creating ICMD®, a SaaS application that allows its users to realize the combined benefits of ICME and cloud computing within their own research and development departments.

The tools of materials creation can now be wielded by innovative industry players who fully embrace the digital transformation.

Many companies are still using technology from 50 years ago for materials development, which is astounding considering that computing power doubles every 18 months now. Where will we see materials innovations make a big difference in the near term?

There are a number of contenders, including semiconductors, where a breakthrough could leapfrog Moore’s Law and have a ripple effect across industries.

What is more likely is that we see material advancements in the energy sector first. New materials will lead to continued development in the solar industry, while hydrogen could take off in a big way if things break (or don’t break) the right way. Nuclear fusion might not make a major leap in 2024, but this is likely a foundational year for the alternative energy source. The work being done now will result in major leaps in the next five years.

Where I expect to see the digital transformation have the largest immediate impact, though, is in batteries.

The reason? We already have the science to make sodium-ion based and even solid-state batteries that are more efficient with greater energy density, qualities that are critical for expanding the range of electric vehicles. The question is whether manufacturing will scale up.

Currently, research and development at traditional upstream materials suppliers is too slow. More and more battery manufacturers and battery-dependent OEMs are realizing this and integrating materials development into their own research and development programs.

Not every company will take advantage of this new era of democratized computational materials design. But it’s worth remembering that it only takes one major breakthrough to transform an industry and pave the way to a more resilient and sustainable future.

Jiadong Gong PhD is CTO of QuesTek Innovations a leader in materials innovation, which recently launched ICMD®, a comprehensive digital platform for materials engineering and design.

Scott Ellyson, CEO of East West Manufacturing, brings decades of global manufacturing and supply chain leadership to the conversation. In this episode, he shares practical insights on scaling operations, navigating complexity, and building resilient manufacturing networks in an increasingly connected world.