Industrial IoT requires rugged, secure connectivity built to endure harsh conditions and deliver lasting reliability.

By Bob Blumenscheid, Senior Product Marketing Manager, Digi International

From EV charging infrastructure and autonomous robotics to precision irrigation and predictive maintenance, the Internet of Things (IoT) is reshaping the industrial landscape. These innovations rely on one fundamental requirement: continuous, secure, and reliable wireless connectivity—even in the harshest, most unforgiving environments.

But in industrial settings, not all connectivity is created equal. The environments are demanding—high temperatures, exposure to moisture, vibration, electromagnetic interference, long-range requirements—and the operational consequences of device failure are far more severe than in consumer or commercial applications.

What connects these use cases is the need for resilient, long-life connectivity solutions that can stand up to industrial realities and keep systems communicating over years or even decades. The stakes are higher than ever—and increasingly, the question is not what IoT can do, but how to build it to last.

Wireless communication modules, sensors, gateways, and the software that binds them together form the infrastructure of any modern IoT deployment. In consumer IoT, modules might be replaced or upgraded every few years. But in industrial use cases—say, embedded into agricultural equipment, factory systems, or warehouse safety devices—these components are expected to function continuously and dependably, often for a decade or more.

As a result, manufacturers and integrators are placing increased emphasis on future-proofing. That includes long-term component availability, consistent manufacturing standards, firmware support, and compatibility with evolving protocols and security standards. In short, they’re treating wireless modules not as accessories—but as strategic infrastructure.

One well-established example is the Digi XBee® line of wireless connectivity modules. With over 25 million modules deployed globally, XBee has become a trusted choice in industrial applications that require long-range, low-power, and rugged communication—often in conditions where consumer-grade options would fail.

Just as important, these types of industrial-grade modules allow customers to migrate to compatible versions as protocols evolve, ensuring investments remain protected over the full lifecycle of the infrastructure.

Autonomous robotic systems are growing more common across industrial landscapes—from agricultural machinery to logistics automation. One prominent example is Husqvarna’s commercial-grade robotic lawn mowers, deployed across expansive campuses, golf courses, and municipal parks.

These autonomous mowers depend on wireless connectivity to augment GPS data with hyper-local telemetry. As the mower returns to its charging station or navigates a set path, it relies on short-range communication to maintain location accuracy and operational awareness.

Modules used in this environment must withstand intense sun, heavy rains, temperature extremes, and ground-level interference from terrain and plant life. Manufacturers turned to industrial-grade wireless solutions that could provide the durability and reliable signal strength necessary to support these rugged, mission-critical functions.

Predictive maintenance is another area where robust IoT connectivity is delivering measurable ROI. Industrial motors, elevator systems, conveyor belts, and HVAC units can all be monitored in real time for early signs of failure. A shift in vibration patterns, for instance, can indicate a degrading bearing or misaligned shaft—long before a critical failure occurs.

National Control Devices (NCD) developed a vibration sensor system specifically for this purpose. Their solution wirelessly transmits data from motors and mechanical equipment to a centralized platform that analyzes trends and triggers maintenance alerts.

The real power of this setup lies in its ability to deploy sensors without wiring them directly to the equipment—providing flexibility and speed in deployment. In elevator systems, for instance, the sensors can help operators maintain contractual uptime guarantees, while in facilities like breweries or distribution centers, they prevent costly disruptions in high-throughput operations.

In agricultural settings—especially in remote or infrastructure-limited areas—wireless modules enable precision monitoring and control. Irrigation pivots, in particular, have seen significant advances in efficiency by incorporating connected sensors and automation.

A typical setup might involve rainfall sensors, soil moisture detectors, and flow controllers working together to inform watering decisions. Rather than applying water uniformly, the system can adjust flow based on soil conditions, recent weather, and crop needs—saving water and energy while maximizing yield.

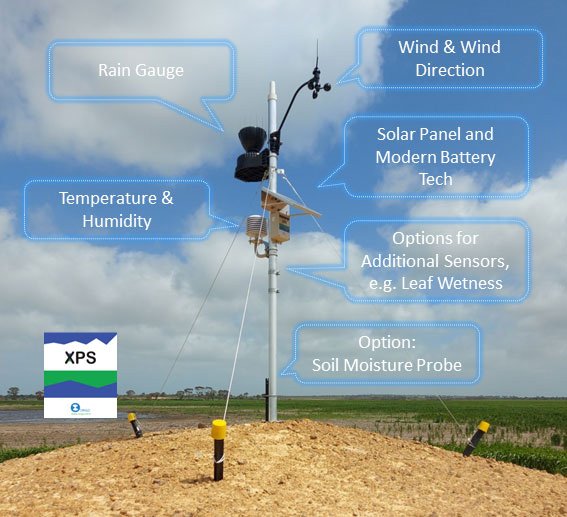

Origo.ag Weather Systems, for instance, combines localized weather stations with remote sensing to enable growers to optimize irrigation schedules and coverage in real time. These systems must endure heavy UV exposure, storm conditions, and seasonal temperature shifts—making the reliability of the wireless module a key factor in the system’s success.

As industrial IoT deployments scale, single-point wireless systems are often insufficient. Instead, organizations are implementing mesh networks—where sensors and devices relay data across a network that can self-heal and adapt as nodes go offline or conditions change.

In one high-profile case, a drone operator achieved a record-setting light show using more than 8,000 synchronized drones. Coordinating that many devices simultaneously required real-time wireless communication—not just between the drones and the control station, but among the drones themselves via mesh networking.

But orchestrating such a massive deployment wasn’t just about rugged hardware. It required a comprehensive lifecycle strategy—from development and configuration to network mapping, on-site testing, and real-time management. Advanced platforms now provide the software and tools needed to code, test, deploy, and maintain these networks at scale—reducing complexity and accelerating time to launch.

This underscores an important point: the most effective connectivity solutions combine rugged hardware with integrated software ecosystems. These allow organizations to simplify configuration, manage firmware updates, and gain real-time visibility across the deployment lifecycle.

In high-throughput warehouses and distribution centers, safety and operational visibility are paramount. At one such facility, wireless modules were embedded in dock lock systems—the equipment that secures trucks in place during loading—to provide real-time alerts if doors are opened prematurely or safety procedures aren’t followed.

Rather than retrofitting hardwired sensors into existing infrastructure, wireless modules made it easy to deploy and scale these systems. By transmitting door status, lock engagement, and environmental data wirelessly, facility managers gained a real-time safety dashboard—and the ability to proactively respond to issues before they escalated.

Across each of these industrial use cases, a pattern emerges: the need for connectivity that lasts.

Future-proofing IoT deployments means designing not just for today’s functionality, but for tomorrow’s requirements. That includes:

Too often, organizations learn these lessons the hard way—when a module goes out of production, or a firmware mismatch causes an outage, or a lack of deployment tooling delays launch. Future-proofing isn’t just about rugged specs; it’s about operational foresight.

The industrial world doesn’t chase trends—it builds for endurance. That’s why future-proofing IoT infrastructure has become a top priority.

As manufacturers, utilities, agriculture firms, and logistics companies integrate IoT deeper into their operations, they need connectivity solutions they can count on. These systems must be rugged, secure, scalable, and supportable—because in the real world, a wireless module isn’t just a line item on a spec sheet. It’s part of the infrastructure.

And in the industrial sector, infrastructure must be built to last.

About the Author:

Bob Blumenscheid is a Senior Product Marketing Manager at Digi with over three decades of experience in technology fields. His roles have included sales engineering and sales management as well as product marketing and business development. In his second stint at Digi, Bob plays a key role in driving product marketing for Digi embedded products.

Scott Ellyson, CEO of East West Manufacturing, brings decades of global manufacturing and supply chain leadership to the conversation. In this episode, he shares practical insights on scaling operations, navigating complexity, and building resilient manufacturing networks in an increasingly connected world.