SAMPE 2024 – pastes and castings based on epoxy and polyurethane for the manufacture of models and molds at Sampe 2024.

Wixom, MI, USA; Burlington, Ontario, Canada, May 16, 2024. Maximum speed and quality, mini- mum cost and waste – RAMPF Group, Inc. is presenting its Close Contour paste and casting portfolio for the production of models and molds at SAMPE 2024 in Long Beach, CA, from May 21 to 23 – Booth D26. A further highlight – holistic engineered solutions for technologically ad- vanced composite manufacturing by RAMPF Composite Solutions.

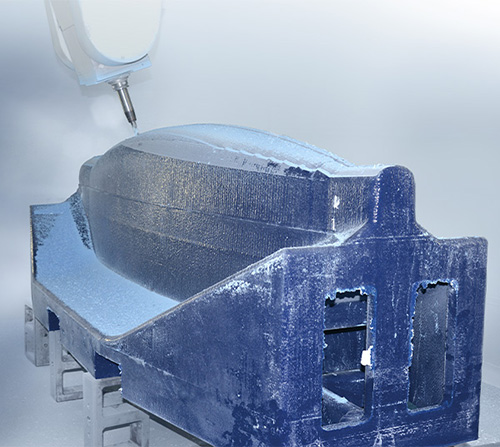

RAKU® TOOL Close Contour pastes and castings based on epoxy and polyurethane are used to manu- facture high-quality models and molds that are already close to the shape of the final part. The benefits:

Close Contour Pastes

The two-component, thixotropic epoxy systems are applied to a close-contour shape supporting struc- ture with a mixing and dispensing machine, cured, and then CNC machined according to customer CAD data; almost any kind of supporting structure can be used, including RAKU® TOOL SB-0080 styling board, EPS, and cast aluminum.

RAKU® TOOL Close Contour pastes exhibit outstanding dimensional stability and enable quick and easy processing with no slump on vertical surfaces and smooth overhead dispensing. Applications include de- sign and styling models, molds, large-scale modeling, rotor blade, wind turbine, and boat models.

RAMPF offers a paste application service and the comprehensive technical support of experienced en- gineers.

Close Contour Castings:

The semi-finished polyurethane systems are supplied as a three-dimensional casting. The monolithic, close-contour block with even wall thickness is manufactured in-house at RAMPF based on customer CAD data.

The cavity is milled into a lightweight mold material such as EPS or RAKU® TOOL SB-0080 styling board. Following the application of the release agent, the cavity is filled using a special casting process. Milling is quick and easy. Applications include styling, design, master, cubing, and data control models.

Quicker time-to-market at lower costs – RAMPF Composite Solutions is presenting its holistic engi- neered solutions for technologically advanced composite manufacturing for the aerospace, defense, industrial, medical, high-end consumer, and green transportation industries.

The company utilizes the full potential of composites manufacturing for both low-volume production / early product development and series production by combining

Together with material qualification, built-in quality assurance, and automation processes, subsystems and fully scalable prototypes are manufactured within days or weeks of design stage via an innovative one-shot solution.

Visit RAMPF at SAMPE 2024 in Long Beach, CA, from May 21 to 23 – Booth D26!

The RAMPF Group stands for Chemical & Engineering Solutions and caters to the economic and ecological needs of indus- try with four core competencies:

RAMPF has subsidiaries in Germany, the United States, Canada, China, Japan, and Korea.

All RAMPF companies are united under a holding company – RAMPF Holding GmbH & Co. KG – based in Grafenberg.

Published by:

RAMPF Holding GmbH & Co. KG

Albstrasse 37

72661 Grafenberg

Germany

T + 49.71 23.93 42-0

F + 49.71 23.93 42-2050

E info@rampf-group.com

www.rampf-group.com

Your contact for images and further information:

Benjamin Schicker

RAMPF Holding GmbH & Co. KG

Albstrasse 37

72661 Grafenberg

Germany

T + 49.71 23.93 42-1045

F + 49.71 23.93 42-2045

E benjamin.schicker@rampf-group.com

Scott Ellyson, CEO of East West Manufacturing, brings decades of global manufacturing and supply chain leadership to the conversation. In this episode, he shares practical insights on scaling operations, navigating complexity, and building resilient manufacturing networks in an increasingly connected world.