Reactive resins and automated dispensing systems for state-of-the-art production processes at NPE 2024 in Orlando, FL – Booth S17184.

Wixom, MI, USA. Material and processing technology for state-of-the-art production pro- cesses – RAMPF is presenting high-performance reactive resins and automated dispensing sys- tems for sealing, casting, and bonding of automotive, aerospace, appliance, electronics, energy technology, lighting, medical technology, manufacturing, molding, and packaging applications at NPE 2024 in Orlando, FL, from May 6 to 10, Booth S17184.

RAMPF is a market-leading manufacturer of

RAMPF sealing systems guarantee long lasting protection from moisture, dust, and chemical influences. The exceptionally easy to handle FIPG and FIPFG foam gaskets are used in both indoor and outdoor applications, exhibit excellent resilience and compression recovery as well as outstanding noise and vi- bration damping, amongst others.

Electro casting resins developed by RAMPF offer a wide range of mechanical, thermal, and chemical properties. The customized reactive resins systems – pot life, viscosity, and thermal conductivity are set according to customer specifications – are used for protecting sensitive electronic components, batteries, power electronics, automotive sensors, transformers, motors, and many more.

RAMPF adhesive systems combine the ultimate in adhesion and strength with excellent temperature and chemical resistance. They are formulated to exhibit a wide range of properties, are easy to process, and perform well on wood, plastic, acrylic glass, aluminum, and other mineral materials.

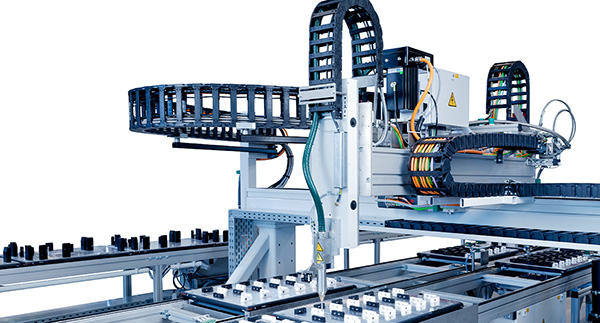

RAMPF is a leading provider of automated production systems with integrated dispensing technology for sealing, casting, and bonding. The company has manufactured more than 3,300 solutions worldwide – from manual systems to fully automated production systems. The product offering includes

RAMPF Group, Inc. also offers cost-effective, flexible, and reliable contract manufacturing services for sealing, casting, and bonding for a wide range of industries and applications.

Visit RAMPF Group, Inc. at NPE – The Plastics Show 2024 in Orlando, FL, from May 6 to 10, Booth S17184!

RAMPF Group, Inc., based in Wixom, Michigan, USA, is a market-leading specialist for

RAMPF Group, Inc., is a company of the international RAMPF Group based in Grafenberg, Germany.

Scott Ellyson, CEO of East West Manufacturing, brings decades of global manufacturing and supply chain leadership to the conversation. In this episode, he shares practical insights on scaling operations, navigating complexity, and building resilient manufacturing networks in an increasingly connected world.