Supply Chain Managers are working to elevate processes through the use of AI.

Artificial intelligence (AI) and machine learning (ML) are quickly becoming key components in the advancement of how manufacturers are working within the supply chain. The technology being applied to supply chain management can streamline processes and improve the safety and efficiency of the companies that employ them.

AI has caught on in the supply chain, and with great reason. McKinsey reported that Sixty-three percent of executives surveyed reported revenue increases with 61 percent reporting cost savings as a result of adopting AI into their supply chain management (SCM). Meanwhile, 61 percent reported revenue gains with 64 percent reporting cost savings from AI adoption in manufacturing.

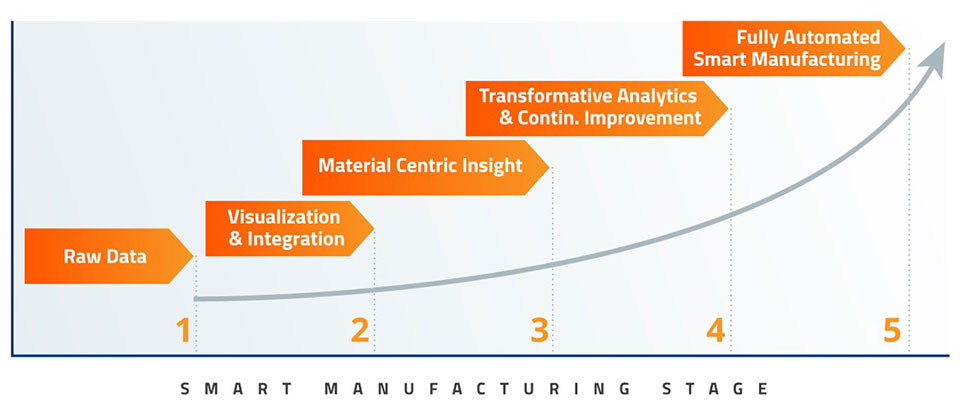

AI brings efficiency through big data analytics and performance insights on an unprecedented scale. With this power, AI is advancing supply chains for a cleaner, more cost-effective future. Preparing for this future starts with understanding AI implementation in the present. It also comes with an understanding of how AI is currently being implemented to improve supply chain processes.

The use of AI will bring a welcomes relief to supply chain managers who want to move away from the typical manual processes that are often used in many organizations. Traditionally, supply chain managers have burned countless hours of labor into gathering data from a multitude of disparate systems, attempting to manually make sense of it all. AI reduces the leg work by orders of magnitude. It’s become not just a “nice to have,” but a necessity considering the mountains of data at hand. Once a business graduates past a certain threshold of data, applications, and variables, it’s simply not feasible for the human mind to account for everything.

Extremely scalable AI that is capable of processing terabytes and petabytes of data can do the heavy lifting now, delivering deep analysis on thousands of SKUs. This opens up extraordinary accuracy in forecasting inventory, supply, and demand. Coupling AI with ML, supply chain planning and decision-making is more agile and optimized than ever. The result: more balanced supply and demand along with faster product delivery, all with minimal human intervention.

Having better warehouse efficiency is another way AI can be beneficial to manufacturers. On average, businesses burn about 6,500 hours per year processing paperwork (about 55 hours per week), adjusting purchase orders (about 39 hours per week), and responding to supplier inquiries (about 23 hours per week). These are tasks that can and should be offloaded to automation software.

In 2016, Google and Baidu spent $20 billion to $30 billion on AI, 90 percent of which was spent on research and development. Amazon and Alibaba have employed automation in the form of machines and robots that box customer orders at their warehouses. Considering the massive scale at these companies operate at and the potential to reduce stocking time by as much as 30 percent using autonomous vehicles, it’s no wonder AI has earned such enormous budgets.

Another advancement through the use of AI will be the use of autonomous trucks. They do possess the potential to solve a major problem in the supply chain. Two years ago, the American Trucking Association estimated a 60,000-driver shortage in the over-the-road truckload market. The problem has only gotten worse with about 80,000 fewer available drivers than a year ago due to new regulations and other pandemic fallout. Also considering strict restrictions that limit drivers to no more than 11 hours per day without an 8-hour break, a driverless truck would present a boon to the industry and the supply chain, effectively doubling the output of U.S. transportation at 25 percent of the cost.

There are many benefits that AI will offer supply chains as the technology advances, and we named a few of them above. However, we will continue to see more advances as the technology behind AI continues to grow. According to Gartner’s 2021 predictions on the Future of Supply Chain Technology, through 2024, 50% of supply chain organizations will invest in applications that support artificial intelligence and advanced analytics capabilities.

There are countless ways in which the use of AI can innovate across supply chains. By extending these tools into any business’s supply chain, cost efficiency can be boosted in multiple ways. It is clear that AI is changing the way in which the supply chain industry works. The benefits we are seeing are already pointing towards a cleaner and more cost-efficient world with the help of AI. As organizations continue to work to adapt to the ever-changing market, we will see more companies looking to continue the uptick in investment in applications that embed, augment, or apply AI and advanced analytics tools. This is a call to action for supply chain leaders as they will need to adopt a broader and more holistic perspective when it comes to AI and advanced analytics in order to keep up with the change of pace.

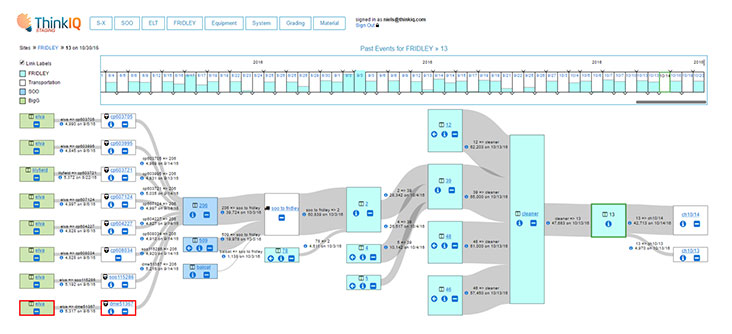

Doug Lawson is the CEO of ThinkIQ, a pioneer of Digital Manufacturing Transformation SaaS.

Scott Ellyson, CEO of East West Manufacturing, brings decades of global manufacturing and supply chain leadership to the conversation. In this episode, he shares practical insights on scaling operations, navigating complexity, and building resilient manufacturing networks in an increasingly connected world.