Supply chain management has long been a component of the oil and gas industry ripe for improvement, and now drones are making that possible.

While some industries have reluctantly dipped their toes into the fourth industrial revolution, or even attempted to resist automation, digitization and connectivity, the same cannot be said for oil and gas. A combination of forward thinking from leaders and decision-makers in the sector combined with the stark cost cutting that accompanied the 2014 downturn has resulted in an industry leading the way when it comes to finding efficiencies and modernizing operations.

One of the biggest ways organizations in the oil and gas industry are optimizing operations is by integrating leading-edge technology into supply chain management. While there is a range of technologies producing benefits for oil and gas companies, there are three in particular that are leading the push into industry 4.0.

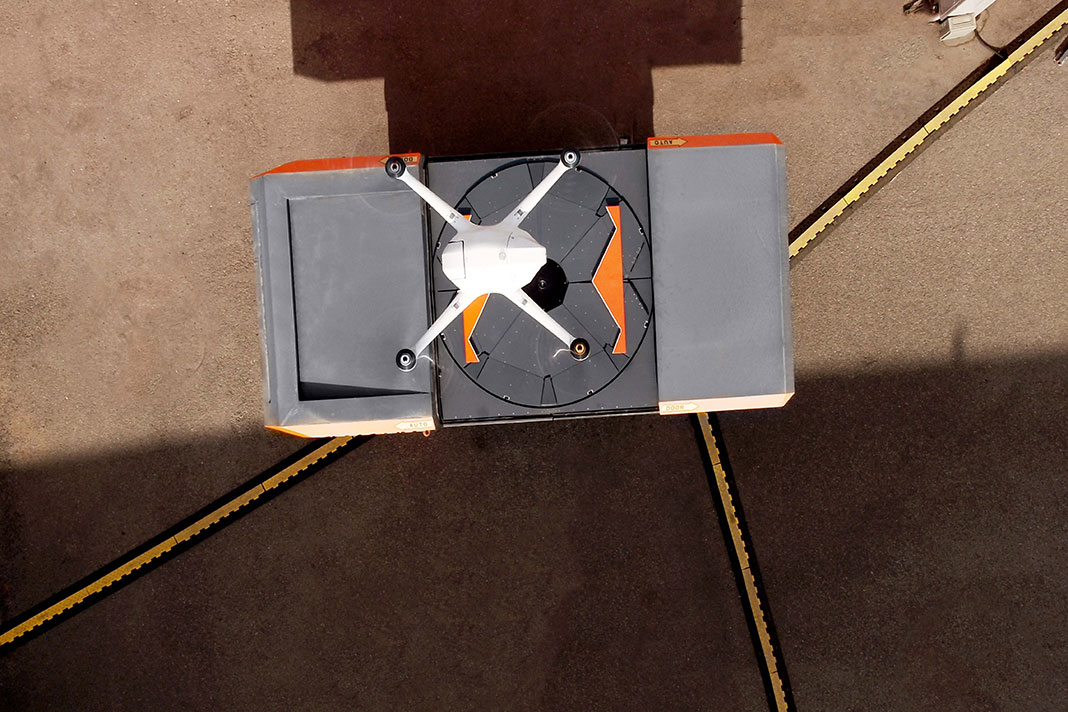

Automated drones for oil and gas are impacting supply chain management.

Highflying, the sky is the limit, lofty potential, yes there are plenty of puns available for describing just how significantly automated drones for oil and gas are impacting supply chain management, but what these industrial drones can do for the inspection process needs no embellishment.

A major part of supply chain management is keeping equipment and infrastructure in good working condition, and scheduled and on-demand inspections are invaluable in that regard. When the downturn hit and the belt tightening began, however, it got harder for many companies to justify the manpower hours, shutdowns, and other costly logistics that go into inspections.

Automated drones are industrial drones built with end to end automation, requiring no pilot and no human intervention for routine maintenance. They offer a quick and cost-efficient way to conduct frequent inspections without incurring the significant costs and delays of traditional inspection processes – not to mention the serious risks presented to human inspectors by oil and gas equipment and infrastructure. Automated drones can easily fly into confined spaces, up the height of flare stacks, to remote areas, and even in poor weather conditions.

The oil and gas supply chain in the past has suffered because, to put it in decidedly non-technological terms, it’s been difficult for the right hand to determine what the left hand is doing and at what rate the left hand is doing it. When the responsibility for communication between different stages of production rests with employees, it’s naturally going to be a process subject to inconsistency as well as the omissions and inaccuracies that can stem from human error.

With industry 4.0’s increased connectivity comes increased data integration and information sharing, both upstream and downstream. This makes it possible to adjust production levels on the fly based on real-time inventory data from storage facilities, distribution rates, upcoming orders and forecasted demand. This makes for a leaner and more agile supply chain that can cut production and its associated costs when necessary and ramp right back up as demand increases.

Companies in the oil and gas industry that have substantial transportation expenditures also relatedly tend to have substantial headaches. It doesn’t have to be that way, however, and that’s where blockchain technology comes in.

Blockchain technology represents a new way to process transactions. Instead of using a centralized database, blockchain has a distributed ledger stored virtually all over the world that nonetheless is able to group transactions together based on participants, such as a supplier and a distributor. It also uses cryptography to secure transactions, and every transaction in the blockchain is independently verified. All in all, blockchain provides a more secure means of processing transactions that cuts out the middlemen, e.g. banks and their associated fees.

For oil and gas transportation expenditures, blockchain provides a transparent and highly trustworthy chain of transactions that makes the auditing process easy enough that third party auditors may not even be necessary to reconcile services ordered with services provided and invoices rendered. Cutting out third party auditing services as well as payment processors can provide significant cost savings to oil and gas companies spending big bucks on transportation.

Supply chain management has long been a component of the oil and gas industry ripe for improvement, and now that technology is making that improvement possible, the industry is hurtling directly towards a fully optimized supply chain.

It remains to be seen what else the fourth industrial revolution has in store for the oil and gas sector. For now, automated drones, data integration and information sharing, and blockchain will bear the brunt of the responsibility for quicker, safer and more cost-efficient, and it will bear that responsibility well.

Jessica Foreman

Jessica Foreman is a Durham University graduate specialising in business and lifestyle based writing.

Scott Ellyson, CEO of East West Manufacturing, brings decades of global manufacturing and supply chain leadership to the conversation. In this episode, he shares practical insights on scaling operations, navigating complexity, and building resilient manufacturing networks in an increasingly connected world.