Recent innovations in DFM tools are helping engineers save time and money on manufacturing.

An increasing number of engineers are embracing design for manufacturing (DFM) to streamline their production workflow. Industry leaders such as Apple, GE, and Samsung have already adopted DFM as part of their standard practices. If you’re using the “over the wall” engineering strategy – one where the design team completes their work and then tosses it to the manufacturing team to figure out production details – it might be a good time to revise your production process. DFM eliminates guesswork from your processes and instead focuses on manufacturing simplicity right from the get-go. In this approach, designers and engineers work together to create, refine, and simplify components prior to production, leading to considerable time and cost savings.

If you’re looking to weave DFM into your process, here are five key principles that will help get you started:

DFM starts with choosing the correct manufacturing method. For instance, high-volume batches might require injection molding, while 3D printing would be best suited for low-volume, detailed parts. This stage also considers the properties of the parts or tools to be created.

Once the manufacturing process is locked, the design phase is next. It involves accounting for factors like wall thickness, surface details, and transitions based on the selected manufacturing process. Simplicity is preferred in DFM since complex geometries can increase the risk of production failure and costs.

Material choice is essential to meet the required properties of the final part. When selecting materials, factors such as heat resistance, water resistance, strength, and flexibility must be considered.

This principle considers where and how the part will be used. Understanding the product’s environmental context ensures its functionality over an optimal lifespan. For instance, parts used indoors may not have to be as robust as those meant for the outdoors.

Industrial regulations apply in many cases, depending on how the part will be used. As such, materials for food industry parts should be non-absorbent and non-toxic, whereas aviation parts require lightweight yet durable materials.

Other factors that influence DFM include the availability of materials and components, design reusability, and aesthetics. The DFM process can help guide your decisions in these areas, and yield benefits such as reduced costs, shorter lead times, and improved part quality.

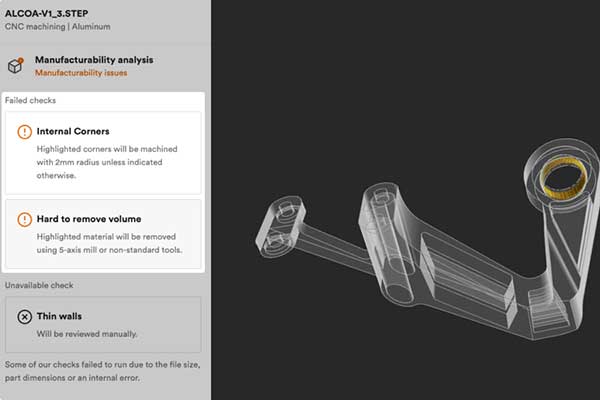

Manufacturing companies, including online platforms, are introducing detailed DFM software to help engineers. For instance, Hubs’ DFM tool highlights potential issues such as inconsistencies in wall thickness, sharp internal corners, and tricky-to remove volume in CNC manufacturing.

Similarly, it addresses mesh integrity and support structure related errors in 3D printing. Earlier this year, Protolabs rolled out its DFM tool that provides a detailed manufacturing analysis along with actionable recommendations to address the issues.

In the future, DFM tools might offer more advanced features. It’s possible that they could identify features to be adjusted to reduce machining time and offer time-saving estimations. Additionally, DFM could recommend optimal machining processes for a particular design and even suggest design changes to make a switch from a 5-axis to a 3-axis CNC.

Francesco Rivalta, Mechanical Engineer at Hubs, would like to see DFM tools that extend beyond just highlighting design issues. For instance, rather than suggesting an increase in the radii of the fillets, the DFM could provide specific values. Advancements in DFM could allow engineers to innovate and iterate more quickly, bringing products to market even faster.

Press Contact:

Chandrakant Isi

chandrakant.isi@hubs.com

Scott Ellyson, CEO of East West Manufacturing, brings decades of global manufacturing and supply chain leadership to the conversation. In this episode, he shares practical insights on scaling operations, navigating complexity, and building resilient manufacturing networks in an increasingly connected world.