One process with three options: rounding, deburring, or calibrating?

In “HydroEROsive” machining—abbreviated as HERO—an abrasive liquid containing grinding particles is pumped through the internal geometry of a workpiece under high pressure. This method of flow grinding can be used to deburr and round components for the automotive industry or to calibrate the flow rate of a bore. Sonplas provides both extensive expertise and the appropriate system solutions.

“Even intricately shaped components often need to be ground, rounded, or deburred on the inside,” says Werner Riederer, Sales Engineer at Sonplas GmbH, based in Straubing, Bavaria. In the automotive industry, these could include injection nozzles for combustion engines or injectors for hydrogen combustion engines. The HERO process is ideal for these specialized applications. “More than half of all diesel injection nozzles worldwide are now flow-calibrated using this method,” explains Riederer.

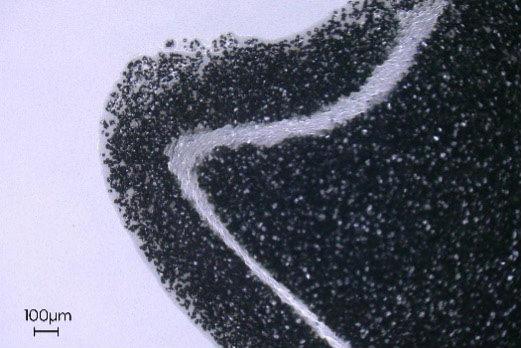

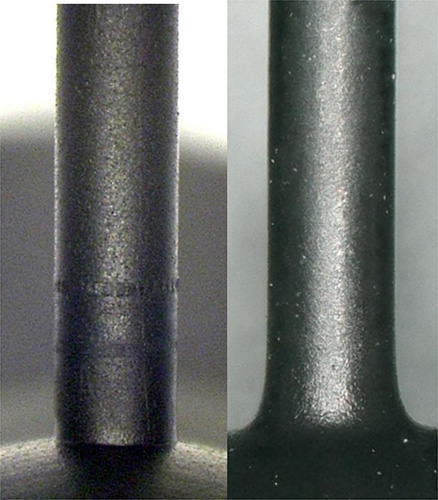

The flow grinding process enables efficient and, above all, controlled deburring or rounding of internal bore intersections. This, in turn, improves high-pressure resistance, ensuring minimal wear even under high pressures—or significantly slowing the wear process. Additionally, it simulates the artificial pre-aging of the component. The user benefits from consistent performance throughout the entire service life of the workpiece. Deburring may be required not only for the functionality of a component but also to enhance ergonomics or aesthetics.

A fluid with abrasive particles flows through the component along the internal bore intersections or bore geometry, much like liquid sandpaper. Werner Riederer provides an example: “Suppose the bore has a diameter of two millimeters and tapers into a bore with a diameter of one millimeter. At the bore taper, an edge forms where abrasive particles collect under high pressure, causing material removal. The extent of this process depends on the fluid pressure and the type of abrasive particles used.”

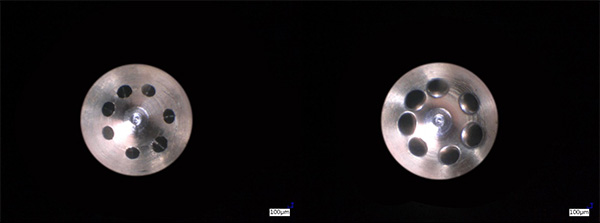

A wide range of workpieces can be processed. “The key factor is always the size of the bore that needs to be machined. Our systems can grind bores with diameters ranging from 0.1 to 5 millimeters,” says Werner Riederer. For example, nozzle bores and holes in injection systems for combustion engines can also be rounded. The workpieces can be made from steel or stainless steel, but aluminum, magnesium, and precious metals such as gold, silver, or platinum are also suitable. Hard metals are also used, for instance in cutting plates for tools, as well as glass, ceramics, plastics, and fiber composites.

The characteristics of the process medium are first specially adapted to the requirements of the workpiece to be machined: optimized rheological specifications are defined in order to achieve the desired flow rates, geometries and degrees of rounding. Depending on the application, the media are formulated to be either mineral oil-based or water-based and adjusted to viscosities ranging from 0.5 to several tens of thousands of mPa·s (millipascal-seconds). The type, concentration, and particle size distribution of the abrasives in the medium play a crucial role in determining the achievable material removal rate and surface finish of the workpieces. Highly abrasive ceramics, such as boron carbide, aluminum oxide, or even synthetic diamond, can be used as abrasive grains. “This versatility allows us to process components with optimized cycle times,” explains Werner Riederer. The grinding fluids, through targeted additives, also serve as effective corrosion protection for the machined customer components. The excellent wetting properties and compatibility with rinsing and testing fluids also allow particles to be easily washed out that cannot be removed by other means. Through intelligent process engineering, the required cleanliness classes according to VDA19/ISO16232 can be achieved as needed. The user benefits from a comprehensive process that enables the elimination of additional costly processing steps. Sonplas also offers a water-based version of the “conventional” process medium. This offers several benefits: It is environmentally friendly, hygienic, and has a low carbon footprint. Furthermore, since it does not pose a risk to groundwater, disposal costs are lower.

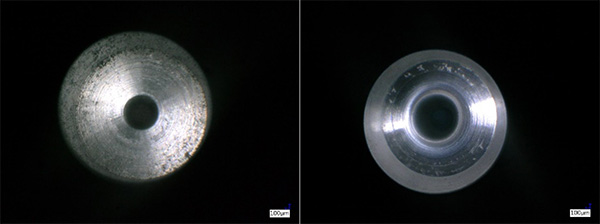

In addition to rounding and deburring, the HERO process can also be used for flow calibration of bores. For this, the user selects a fluid with low viscosity. Werner Riederer provides a typical example: “The injection nozzle in engine technology has a flow rate of 900 ml/min after the bore has been eroded. We place the component in our system, round off the inlet edges of the injection holes, and increase the flow rate by 10 to 40 percent.” After the HERO process, the nozzle in this example has a flow rate of 1,000 ml/min. It offers a significant advantage: after erosion, the accuracy of the bore is ±3 percent, whereas after the HERO process, it is a reliable ±1 percent. With hydroerosive machining, the user can precisely calibrate the flow rate on their workpieces. The operator can monitor the increasing flow rate online throughout the entire process, accurately adjust the required value, and set the flow tolerances with reliable process control.

Whether deburring, rounding, or calibrating, the user has three different application options available with hydroerosive machining. By adjusting the respective parameters, they can meet the various machining requirements reliably and reproducibly. “The process thus satisfies all drawing and component specifications,” explains Sonplas expert Riederer.

Sonplas also equips the systems with rotary tables, enabling processes such as grinding, rinsing, and/or measuring the flow rate to run in parallel. Depending on the requirements, each component can pass through up to eight stations. The slowest work step determines the cycle time. The user can adapt the custom machine to their needs on a modular basis and, for example, integrate additional process stations, such as rinsing or measuring devices, at a later stage. Databases and MES systems can also be integrated. Corresponding component markings (DMC) allow for seamless tracking of machining and process data. “Flow control and master parts, which the integrated software introduces into the process at specific intervals and checks regularly, are also available,” says Werner Riederer.

As the machines operate within a closed system, no operator errors can occur. The person at the machine only needs to handle manual loading or change the pallets if necessary – the process runs consistently. For higher production volumes, automatic loading is also possible, such as with a robot loading module. “This also enables us to link processes together,” explains Werner Riederer. For instance, the loading module can be positioned after erosion or laser drilling and before HERO machining. The customer then simply loads the workpiece and retrieves the drilled, deburred, or calibrated component at the other end, which is placed neatly on a pallet. “We provide our customers with everything from simple development machines to systems designed for large-scale production,” emphasizes Werner Riederer.

Sonplas GmbH:

Sonplas is a medium-sized machine manufacturer located in Straubing, Lower Bavaria. Since its establishment in 1993, the company has experienced consistent growth and now employs approximately 390 highly motivated employees. In alignment with the motto “For your success,” Sonplas specializes in developing flexible and scalable specialist machines for processing, assembly, and testing. These can be complemented with external technologies as per the customer’s specifications. Over the years, the portfolio has consistently grown, and the specialist machine manufacturer now provides solutions for various sectors including electromobility, battery cell production, hydrogen technology, hydroerosive machining, fuel injection, electronics, mechatronics, hydraulics, and aerospace technology. To date, the company has delivered over 1,000 specialized machines worldwide to renowned clients in the automotive, automotive supply, commercial vehicle industries, and aviation technology sector.

With its in-house research and development department, Sonplas is well-positioned to meet the latest technical requirements in the market. The company also supports its customers with expert knowledge and spare parts locally through global service partners and a branch in China. What sets Sonplas apart is its deep expertise and understanding of processes. Sonplas serves as both a system integrator and general contractor, delivering customized solutions of the highest quality to its customers.

Images Source: Sonplas GmbH

Scott Ellyson, CEO of East West Manufacturing, brings decades of global manufacturing and supply chain leadership to the conversation. In this episode, he shares practical insights on scaling operations, navigating complexity, and building resilient manufacturing networks in an increasingly connected world.