To decarbonize, we’ll need to deliver 24/7 zero-carbon renewable energy, and clean hydrogen has proven to be a necessary, scalable solution.

By Laura L. Luce CEO of Hy Stor Energy

With the United States and 72 key trading partners having net zero targets enshrined in legislation or outlined as a goal in policy documents, and more than 100 other countries having proposed or considering net zero targets, it is critical to expand the supply of zero-carbon power (and feedstocks) across industries. Direct emissions from heavy industry sectors, like steel, cement, glass and chemical production account for more than one-sixth of total CO2 emissions from the global energy system. As industries work collectively to decarbonize operations and meet net zero goals at corporate, local, national and global levels, new sources of federal funding in the United States, like the Inflation Reduction Act (IRA) and Bipartisan Infrastructure Law (BIL), are catalyzing economical ways to decarbonization.

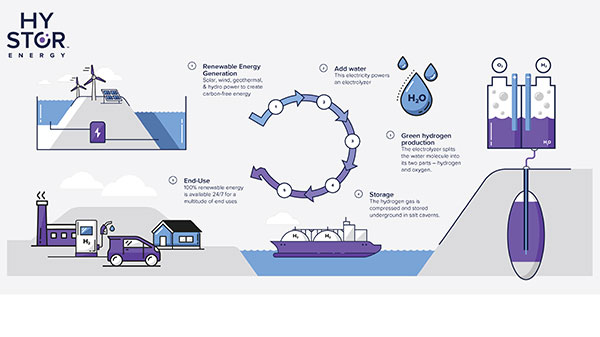

Included is the DOE’s U.S. National Clean Hydrogen Strategy and Roadmap, which offers framework for accelerating clean hydrogen production, transport, storage and use. To decarbonize, we’ll need to deliver 24/7 zero-carbon renewable energy, especially to these hard to abate industries, and clean hydrogen has proven to be a necessary and scalable solution.

Hydrogen, in many cases, is the only solution for decarbonizing certain sectors of the economy, while for many others, it is the most viable. Thanks to its reliability, scalability and cost-effectiveness when compared to other renewable resources and electrification, hydrogen is an ideal source of power and chemical feedstock. Hydrogen is optimal for a variety of industrial operations including glass, steel, fertilizer, petroleum refining, chemical production and food processing.

Reliable, 24/7 access to affordable hydrogen is essential to facilitate a transition to low emissions impact operations across hard to abate industries, but it must be “clean” hydrogen, or hydrogen that is produced in a very low, or ideally zero carbon, intensive process. Only clean hydrogen is an effective decarbonization agent for industry.

One way to ensure consistent hydrogen delivery is by pairing renewable hydrogen production with on-site storage. When hydrogen is stored for weeks, months or seasons, and delivered to large industrial customers on-demand, it becomes a more secure, and hence valuable, source of energy than intermittent renewable generation like solar and wind alone.

The decarbonization gold standard is “green” hydrogen, where production is powered by renewable energy, rather than grid-tied, electrolyzers drive demand for fossil fuel-fired generating resources. The U.S. Treasury is set to release guidance shortly defining “clean” hydrogen for purposes of the clean hydrogen production tax credit (Section 45V). The most important topic that should be addressed in this definition is guidance for evaluating the lifecycle emissions and carbon accounting for grid-connected electrolyzers. Weak guidance could lead to subsidizing hydrogen projects that may add emissions rather than decrease emissions.

When defining clean hydrogen, the U.S. should look to places such as Europe which have adopted effective requirements for clean hydrogen. For thoughtful implementation of the tax credit in the E.U., there must be clear and transparent quantitative measurement of emissions based on carbon intensity of inputs. As the United States introduces legislation, it must look to lessons learned from Europe and its requirement for additionality. At the end of the day, we need to ensure that clean hydrogen is contributing to decarbonization and not, in fact, adding to carbon emissions.

Section 45V represents the largest single hydrogen subsidy in the United States (and potentially the world), so strong standards will be critical for creating transparent markets. Smart regulation will catalyze investment and deployment of clean energy generation in a way that supports LONG-TERM economy-wide decarbonization.

Hydrogen hubs, or sites with on-site hydrogen production and storage, that also have access to reliable transportation infrastructure will be most impactful for industrial decarbonization. Momentum for these sites will only continue, backed by funding programs like the DOE’s Regional Hydrogen Hubs. By co-locating manufacturing and production facilities to hydrogen hubs, leaders in heavy industry can make strides in decarbonizing their operations and leading the energy transition. In particular, sites with dedicated, new renewable resources that power hydrogen production will help industrial customers be more confident in resource cleanliness, availability, reliability, delivery timelines and costs.

Growing a clean hydrogen ecosystem that includes co-located industrial off-takers and regional transportation entities to facilitate the movement of hydrogen will boost local economies and help establish a new clean energy workforce. The power of clean energy education and co-location for legacy industries will create more opportunities for on-site job training and apprenticeship. As heavy industries transition to clean energy, hydrogen hubs offer a path to sustainable job creation and growth as well as new, low-emission manufacturing capacity. Community and regional benefits brought on by reduced emissions, include improved air and water quality. Truly clean energy and industrial decarbonization offer not only economic benefits but also environmental justice benefits, in the form of reductions in air emissions and enhancement in the available of clean energy – an increasingly important focus for governments, consumers and industry.

Led by energy storage industry and hydrogen technology veteran Laura L. Luce, Hy Stor Energy is facilitating the transition to a fossil-free energy environment by developing and advancing renewable hydrogen at scale. Its large, fully integrated projects will produce, store and deliver carbon-free renewable energy, providing customers with safe, cost-efficient, and reliable renewable energy on-demand. Developed as part of a scalable integrated hub, these projects couple on-site renewable hydrogen production with integrated long-duration energy storage. Hy Stor Energy has an innovative team with deep expertise and is positioned as a leader in the renewable hydrogen revolution. For more information, please visit www.hystorenergy.com, or follow us @hystorenergy.

Scott Ellyson, CEO of East West Manufacturing, brings decades of global manufacturing and supply chain leadership to the conversation. In this episode, he shares practical insights on scaling operations, navigating complexity, and building resilient manufacturing networks in an increasingly connected world.