Ignion, a IoT antenna innovator announced the launch of Oxion™, a development platform to shorten the design time of wireless devices.

Sant Cugat de Vallès/Embedded World, Nuremberg – Ignion, a Barcelona based IoT antenna innovator, announced today the launch of Oxion™, a development platform to shorten the design time of wireless devices. Powered by AWS, IoT device developers can leverage the power of AI/ML in real-time to avoid wireless connectivity roadblocks and make their projects materially easier to get to market. Oxion™ de-risks the process through accurate performance prediction and device-tailored design guidance powered by proprietary algorithms leveraging real-world experience from enabling more than 50 million wireless devices.

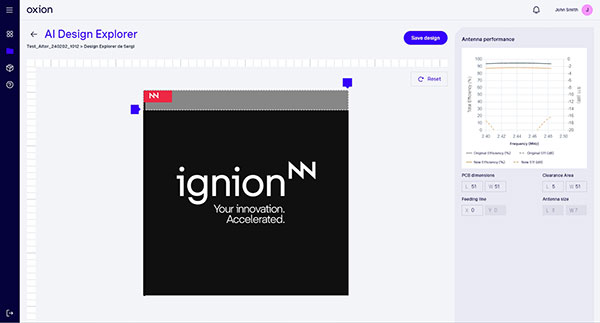

Developers are no longer solely reliant on what is provided in a static component datasheet as Oxion™ now provides an interactive digital twin that matches the exact device requirements.

“All good ideas deserve optimal wireless connectivity, and with the installed base of connected device reaching 70 billion in 2026 according to ABI Research, we need to provide easy access and scale our efforts as an industry” stated Jaap Groot, CEO at Ignion. “It is this spirit of transparency and democratization using the technological evolution of AI which drove us to create Oxion™.”

The development of this user-friendly and free to access platform was made possible through a grant from the European Union Innovation Council’s Accelerator program. The highly competitive funding program allowed Ignion to work with Barcelona-based AI/ML experts, Basetis, who contributed their expertise in developing proprietary algorithms including active learning that power the real-time results engine.

Oxion™ builds on top of Ignion’s successful Antenna Intelligence Cloud™ launched in 2022 and empowers anyone, regardless of their level of RF expertise. Interactive design and meeting the project’s RF specifications now becomes as easy as building with LEGO. The real-time drag and drop functionality with immediate performance feedback allows developers to tweak the design and decide on antenna component, placement, clearance, and PCB size. Once registered, the users are presented tailored recommendations for the specific device being built and Oxion™ acts as the developer copilot from concept to production. Once ready to build hardware, Oxion™ includes direct access to Ignion’s distribution channels to easily procure Bill-of-Materials in one go. Multiple projects can be managed by multiple users and compared all through one dashboard. The result is a de-risked design process avoiding endless trial-and-error steps and letting users get wireless connectivity right the first time.

“Oxion™ is a unique offering that will save wireless developers time and cost,” said Dan Shey, Vice President of Enabling Platforms at ABI Research. “It is exciting to see Ignion embrace the innovation that AI/ML can deliver when combined with their years of expertise.”

The Oxion™ platform will be demoed at Embedded World, Nuremberg April 9-12 at the Ignion booth 4A-302. For further info visit https://oxion.ai

About Ignion

Founded in Barcelona, Spain, as an independent antenna product business in 2015, the Virtual Antenna® technology is already embedded in more than 50 million IoT and wireless devices worldwide. Ignion has assembled a leading R&D and engineering team to make RF easier and more predictable using their revolutionary antenna products and ground-breaking cloud services that meet the ever-evolving requirements of IoT wireless connectivity.

Ignion has corporate offices in Spain, USA, and China as well as several strategic partnerships with the leading module makers and transceiver OEM’s.

Press contact: Raquel.Arribas@Ignion.io

PR Contact:

Elaine Hodson

Account Director

Napier Partnership Limited

elaine@napierb2b.com

T +44 (0) 1243 531123

Scott Ellyson, CEO of East West Manufacturing, brings decades of global manufacturing and supply chain leadership to the conversation. In this episode, he shares practical insights on scaling operations, navigating complexity, and building resilient manufacturing networks in an increasingly connected world.