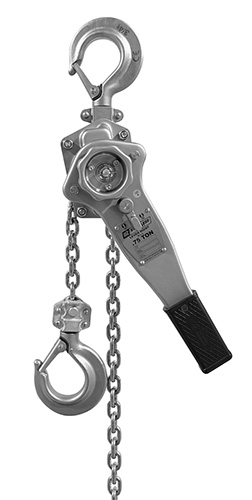

Winona, Minnesota-based OZ Lifting Products LLC has launched North America’s first stainless steel lever hoist, in 0.25- to 3-ton capacities.

The hoist is available in 0.25-, 0.75-, 1.5-, and 3-ton versions; and each one can be provided with 5 ft., 10 ft., 15 ft., and 20 ft. lengths of lift, but custom rigging is available. It joins three other products — chain hoist, push beam trolley, and beam clamp — in the company’s Type 304 stainless steel range.

It is also the fourth lever hoist, in addition to an industrial model, in 0.25- to 9-ton capacities; a premium version, in 0.75 to 9 ton; and, in the same capacity range, the dynamometer-equipped Dyno-Hoist. The stainless steel version closely mirrors the industrial product but is designed for more demanding sectors.

The benefits of Type 304 are many and varied. It is widely accepted as the most versatile stainless steel, which is why it is commonly the manufacturing product of choice for use in demanding markets. The smooth, non-porous surface makes it easier to clean and maintain, which is especially important in environments where hygiene is a concern.

Most notable however for excellent corrosion resistance, Type 304 stainless steel is lauded by many end user sectors, including water treatment; pharmaceutical and food production; and mining. It is suited though to any environment that has corrosion issues, such as those around saltwater, rain, snow, or high humidity.

Steve Napieralski, president at OZ Lifting, said: “Our stainless manual hoists have been very successful, so it was a natural next step to extend the line to include lever hoists. The hoist offers increased resistance to wear and tear, meaning it has a longer lifespan, reducing replacement costs, even when subject to repeated use.

“This capacity range will likely suit most applications but, as always, we will listen to the supply chain, and if we get inquiries for larger sizes, we will certainly add them.”

The hoists are lightweight and easy to operate; they are ideal for use in confined and enclosed spaces, while the effort required on the lever to lift a full load is 20.20 lbs., 28.10 lbs., 41.50 lbs., and 42.70 lbs. respectively. Lever hoists can be used for lifting or pulling but, like the standard line, they will most commonly be found in tensioning applications.

Similarly to OZ Lifting’s stainless steel trolleys and manual chain hoist, the lever hoist features food-grade grease, that meets NSF H1 standards, for end users looking for tensioning or lifting in areas that cannot have any contamination around food. The way the hoist is configured means that the brake is not near where the gearing is located. The owner’s manual outlines proper maintenance procedures.

Other key features include a free wheel for quick adjustment; 360-degree handle rotation; and a Weston-style brake system. They will be supplied with forged hooks and stainless steel riveted identification tags. Napieralski also pointed to the twin-pawl design; sealed roller bearing; and rubber grip.

He added: “We anticipate interest in individual units and multiples thereof. We do a fair amount of custom rigging on many of our products so we will be prepared to quickly meet requests for custom lengths. We will continue to bring innovative products to the market; we have several on the horizon.”

The stainless steel lever hoist will be available for delivery to OZ Lifting’s network of regional dealers from June.

Contact for editorial inquiries: Ashley Blum, marketing manager, OZ Lifting Products LLC; ashley@ozliftingproducts.com

Scott Ellyson, CEO of East West Manufacturing, brings decades of global manufacturing and supply chain leadership to the conversation. In this episode, he shares practical insights on scaling operations, navigating complexity, and building resilient manufacturing networks in an increasingly connected world.