McKinsey research has identified five elements that could create the operational excellence needed to jump-start productivity growth.

Manufacturers across the world remain challenged by slowed productivity growth, shaped by factors such as diminished returns from technology transformation and as well as high churn and poor knowledge transfer among frontline workers.

The stubborn productivity picture is an invitation for organizations to try new ways of doing things. Focusing on five key elements could result in a potential 10 percent increase in customer satisfaction, 20 percent reduction in CO2 emissions, and 25 percent improvement in employee retention—alongside a major boost in productivity—based on similar efforts by businesses across sectors.

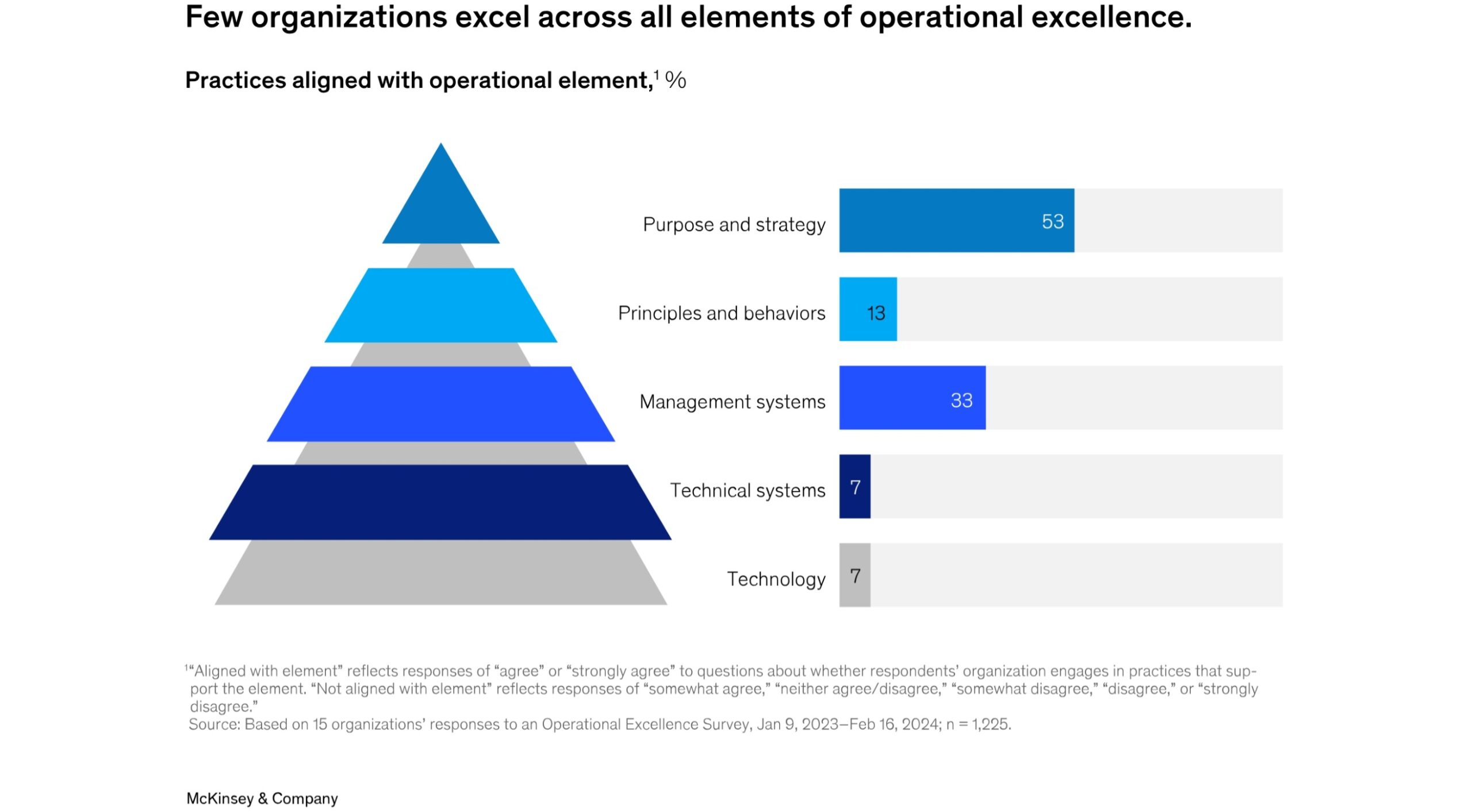

However, achieving operational excellence is no easy task. Our Next-Generation Operational Excellence Survey (NGOES) and Operational Excellence Survey (OES) reveal a number of barriers to operational excellence and productivity growth.

For example, only 30 percent of organizations successfully scale and sustain digital improvement. And while operational excellence was shown to increase the value that can be generated from technologies, the surveys indicate that companies often struggle to take full advantage of the potential offered by 4IR and gen AI technologies to improve productivity across the value chain.

There is some regional nuance to the productivity challenge. In Latin America, for example, frontline workers and middle managers are optimistic about the operational progress being made, while in Asia-Pacific, respondents, on average, reported lower levels of adoption of operational excellence practices.

The surveys point to five elements that together can transform operational excellence and boost productivity:

Meaningful purpose aligned with strategy. Purpose correlates with performance, as demonstrated in McKinsey research on attrition and attraction trends, which found that 70 percent of surveyed employees look to their work to define their individual purpose. Yet only half of the OES and 40 percent of the NGOES respondents felt their organization’s purpose and strategy were reasonably clear and aligned with their own day-to-day work, and only 7 percent of organizations excelled in all the elements of operational excellence.

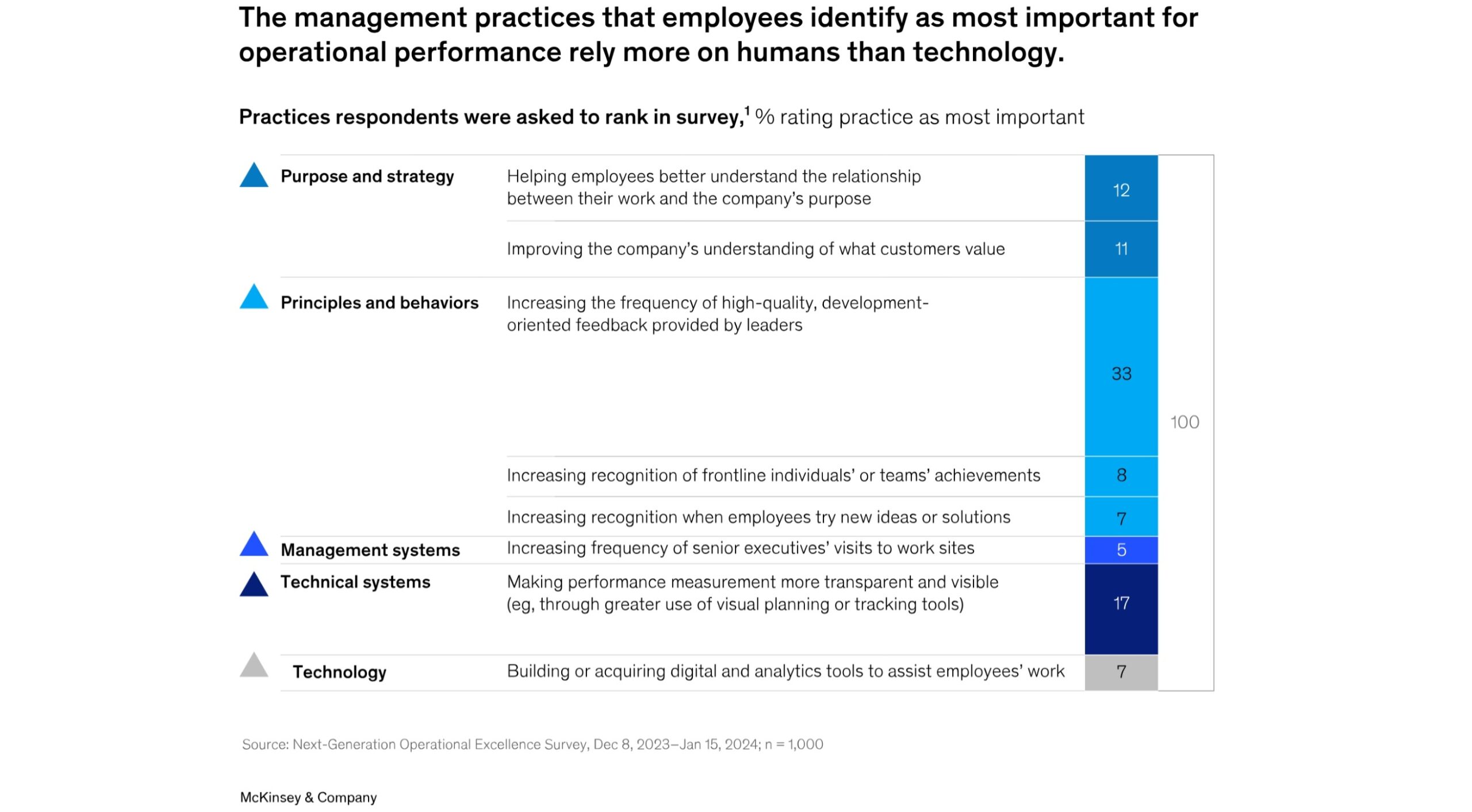

Feedback boosting employee engagement. While research shows that regular feedback improves engagement at work, our surveys exposed gaps in recognizing performance and providing feedback. Less than a quarter of respondents said leaders at their organizations were expected to provide development feedback and only one in five felt their organizations systematically recognized employee achievements (individually or as a team). In general, respondents see greater transparency in performance management, along with regular feedback, as the two best ways to increase learning and improve performance.

Greater impact from innovation. To spark continuous innovation and improvement requires management structures and processes that reinforce behaviors, develop leaders, and increase capabilities. However, only 21 percent of respondents have check-ins at least once a week (usually superficial or limited in scope), while less than half are actively involved in developing operational improvements. This leads to lost opportunities for identifying and solving issues before they escalate.

Overlooking the value of visual tools. Visual tools help to create performance transparency, yet are often overlooked. At best, only about a quarter of respondents’ organizations use visual tools to support essential tasks and almost all respondents think their organizations do not use visual tools well.

Technology not translating into performance. Despite technology underpinning the other four elements, 93 percent of respondents think it does not impact performance enough. Almost three-quarters believe their organizations do not have specific processes to build business cases for new digital tools.

Together, the findings suggest that companies are underinvesting in five key practices that could help them achieve sustained operational excellence:

First, creating a clear relation between work and purpose requires a disciplined internal communications program that continually reinforces a company’s purpose and how that purpose relates to the work employees do.

Secondly, understanding customer needs enables all employees to gain greater appreciation of their work. For example, a chemical company sent non-customer-facing production staff to visit agricultural customers and observe first-hand the negative impact of any quality deviations in products.

Third, the largest performance gap lies in organizations not providing development-oriented feedback. Training managers in providing better feedback could enable employees to make improvements and have a better understanding of potential career pathways.

Fourth, recognizing achievements requires a well-designed, fully integrated, and regularly updated recognition program that reinforces a wide range of operational excellence practices and outcomes at individual and group level.

And finally, visual tools help to create transparency about performance and our surveys show that exceptional organizations remain disciplined in their continuous use.

Adopting an approach based on these five key elements has helped a basic-materials company reduce costs by 20 percent over three years, while increasing output by more than ~30 percent.

To create next-generation operational excellence and related growth, companies need a clear vision, commitment to transform practices across the organization, and objective operational assessments that support the reimagination of end-to-end processes.

Richard Sellschop is a senior partner in McKinsey’s Connecticut office.

Read more from the author:

“Breaking operational barriers to peak productivity,” McKinsey & Company, October 2024

“Today’s good to great: Next-generation operational excellence,” McKinsey & Company, January 2024

Scott Ellyson, CEO of East West Manufacturing, brings decades of global manufacturing and supply chain leadership to the conversation. In this episode, he shares practical insights on scaling operations, navigating complexity, and building resilient manufacturing networks in an increasingly connected world.