To ensure the reliability of an actuator under service, a load test is performed to provide more data for the SIL calculation.

Montreal, Quebec, Canada

For over 65 years, Cowan Dynamics has continued leading the way with our innovative valve automation solutions. Our SIL-3 Capable products are used globally in harsh environments and are chosen for their safety features, product performance, and reliability. For this reason, all our products go through a SIL analysis and certification process, this is no different for our newest addition the E2H-ESD, which is currently going through this process

The E2H-ESD is an electro-hydraulic actuator that has been designed to operate emergency shutdown valves (ESDV). As part of the SIL certification process, cycle testing of the unit was done to determine if, and when, a component may fail, to ensure repeatable and reliable operation of the unit, and to quantify the temperature rise of the different components which will dictate the duty cycle of the equipment for the specific ambient temperature range of the operating environment. This test is expected to complete a minimum of 20,000 cycles, when completed it extended to over 26,000 total.

In addition, stand-by testing was performed. ‘Standby time’ is the time that the unit can stay in the ‘Reset’ position before the hydraulic pump needs to be started to recharge. This time for the ESD valve is crucial because the valve will remain in the ‘reset’ position for a long period of time. A system that is not capable of staying in the ‘reset’ position for a long time will result in a high energy consumption system. Once our test was completed it concluded that the system could maintain the valve in its ‘reset’ position for over a month without the need of starting the hydraulic pump to recharge.

To ensure the reliability of the actuator under service, a load test was also performed to provide more data for the SIL calculation. This article will provide detail on the importance of SIL certification to ensure safety and reliability.

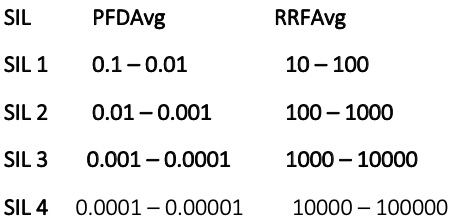

Each SIL is represented in the following table with its associated Average Probability of Failure on Demand (PFDAvg) and Average Risk Reduction Factors (RRFAvg).

In accordance with the IEC 61508, SIL 3 is one of the highest levels of safety integrity. An average risk reduction factor of 1.000 – 10.000 is applied to failures on demand, and 10-8 – 10-7 is applied to failures per hour.

A Safety Integrity Level (SIL) is a method for analyzing and qualifying the requirements for safety instrumented systems. In simple terms, SIL is the level of redundancy of risk-reduction provided by a safety function of how many steps or safety devices do I have in my system that prevent the system from malfunctioning?

To help operators quantify the safety performance requirements for hazardous operations, the International Electrotechnical Commission (IEC) introduced the following industry standards:

IEC 61508: 2010 Functional safety of electrical/electronic/ programmable electronic safety-related systems

In the hydrocarbon and oil and gas industries, these standards have been widely adopted to define Safety Instrumented Systems and their reliability to improve safety and availability.

Scott Ellyson, CEO of East West Manufacturing, brings decades of global manufacturing and supply chain leadership to the conversation. In this episode, he shares practical insights on scaling operations, navigating complexity, and building resilient manufacturing networks in an increasingly connected world.