New model gives buyers clarity, accuracy and transparency.

Manufacturers everywhere are taking a closer look at how they design, sell, and support the equipment they build. Buying behavior has shifted, largely because people are used to digital convenience in their personal lives. Today’s consumers expect straightforward pricing, options that fit their situation, and clear updates as an order moves forward. These expectations shape how they evaluate suppliers and how they decide who earns their business.

The shift is especially visible in industries where products are highly customized and production steps depend on close coordination. Companies that rely on disconnected systems and manual handoffs are finding it difficult to keep pace with the expectations of digital-native buying teams. Many buyers prefer to gather information independently, and a growing number complete most of the evaluation process long before they speak with a representative. This signals a broader change in how trust is formed and how value is defined.

Many manufacturers run into trouble because their internal structure does not reflect what buyers now expect. Sales, engineering, and production often work in their own systems, each holding a slightly different picture of the product. That separation creates avoidable errors that wear down the buying experience. Quotes become inaccurate when they are based on old data. The end result? Production teams end up guessing what was promised to the customer, and delivery dates slip. The root issue is simple: information that should be shared across the organization is instead kept in separate systems, and every team is forced to make its own interpretation.

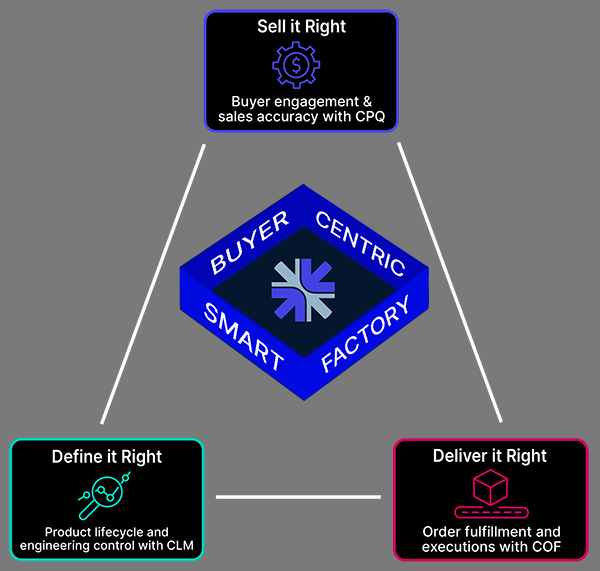

A buyer-centric smart factory gives manufacturers a way to move past these long-standing challenges. By bringing data, rules, and workflows into a shared environment where every team works from the same information. Buyers feel the difference because proposals are accurate, lead times are more predictable, and updates are based on verified data rather than assumptions. Sales teams no longer build quotes from guesswork or outdated catalogs. Engineering contributes the rules that define what is possible, and those rules are applied automatically as configurations change. Production receives manufacturing details that reflect what has been sold, allowing schedules to be set with far greater confidence. The entire process becomes clearer and more consistent, which helps buyers move forward with decisions.

But you can’t just flip a switch or purchase out-of-the-box software to upgrade to a buyer-centric smart factory. It takes a lot more than that, starting with a shift in mindset where collaboration becomes a priority. The first step is to reimagine processes with the buyer’s experience in mind and then start to build those processes. When teams pay attention to what the buyer needs to learn and decide at every stage, they see openings to streamline the journey. Often this begins with aligning configuration rules across teams, so the information buyers receive is consistent and dependable. It may also involve tightening the connection between sales and production so that lead times match what the factory can reliably deliver. Efforts like these give buyers the clarity they expect while simplifying the work of internal teams.

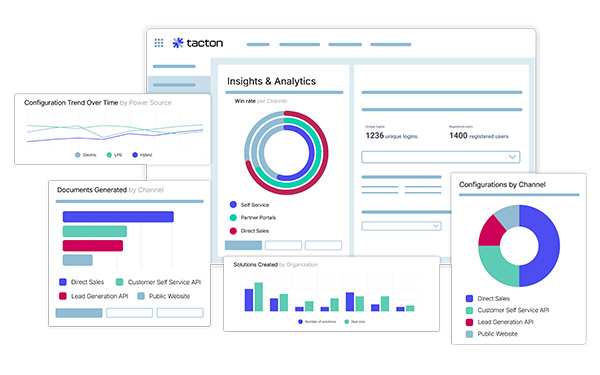

The second step is to use analytics and AI to support decisions with real data. Factories generate huge amounts of information from sales interactions, engineering updates, order changes, and product performance in the field. When this information stays in separate systems, it cannot guide planning or decision making. But once data is brought together in a unified view, manufacturers gain visibility into demand shifts, material requirements, and upcoming service needs. AI can apply engineering rules the moment a configuration changes and warn teams about issues early. Analytics show patterns that inform production planning, product variations, and service strategies. The result is stronger internal coordination and a buying experience with fewer surprises.

The third step is to create and reinforce stronger collaboration across the value chain. Manufacturers that share reliable data with suppliers and logistics partners make it easier for each participant to work toward shared outcomes. Clear demand signals help suppliers plan materials more accurately. When scheduling information is accurate and consistent across the organization, logistics teams can plan shipments with fewer setbacks. Buyers feel the impact through steadier deliveries and clearer communication. Over time, this level of reliability builds trust, and buyers start to view their suppliers as partners who understand their goals.

A buyer-centric smart factory also supports customers long after the equipment arrives. Today’s buyers want systems that run dependably and can evolve with their needs. A unified view of what has been delivered gives manufacturers the ability to anticipate maintenance, recommend upgrades, and tailor support. When buyers experience this kind of attention throughout the lifecycle, they gain confidence in the relationship.

This approach also changes how manufacturers use information from products in the field. Data on performance, service history, and day-to-day use gives teams insight into how equipment can be improved. Those insights influence future designs, shape configuration choices, and guide new service programs. When this feedback loop is working, buyers receive products and support that keep pace with their needs. Manufacturers who organize their work around these expectations are better prepared for the demands ahead. They reduce errors, protect margins, and shorten the time it takes to move from inquiry to delivery. Buyers receive clearer proposals, steadier communication, and more predictable outcomes. These improvements strengthen the relationship between supplier and buyer and create a foundation for long-term collaboration.

Buyer expectations are only going to grow as digital tools shape more of the decision-making process. Manufacturers that focus on connected systems, unified data, and better teamwork will be better prepared to respond. Factories that center their work on the buyer will stand out in markets where trust and consistency matter. Teams that start making these changes today will be ready for a future that rewards transparency and dependable results.

About the Author:

Klaus Andersen is Chief Executive Officer of Tacton, a global leader in buyer engagement software that empowers manufacturers to build a more buyer-centric Smart Factory. With more than 20 years of executive experience, Klaus has led multiple global technology companies through successful transformations, driving innovation, scale, and strong business outcomes.

Scott Ellyson, CEO of East West Manufacturing, brings decades of global manufacturing and supply chain leadership to the conversation. In this episode, he shares practical insights on scaling operations, navigating complexity, and building resilient manufacturing networks in an increasingly connected world.