Physical AI gives machines 3D awareness, bridging design, operations, and quality in real-world factories.

By Alex de Vigan, CEO and Founder, Nfinite

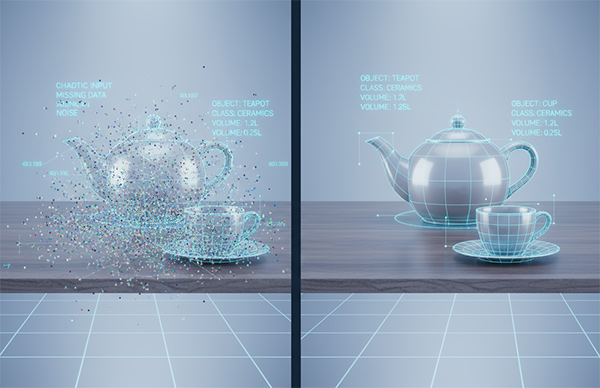

In the race to digitize, many manufacturers have piled on analytics, machine learning, and digital twins. Yet time and again, AI projects underdeliver. Why? Because most systems still lack a sense of space. They ably interpret numbers and pixels, but they don’t truly understand the geometry and context behind them.

Physical AI—AI grounded in detailed 3D spatial models—changes that. It lets machines perceive the physical world, reason about it, and adapt to variation. Below I walk through why legacy AI often disappoints, how 3D twins are evolving into operational infrastructure, and what lessons industrial automation can borrow from retail’s early forays into Physical AI.

You’ve probably seen it: a visual-inspection pilot works beautifully in the lab, then fails in the field. Or a predictive-maintenance model flags anomalies, but few of them are actionable.

Here’s what typically holds those systems back:

Physical AI reorients this. Because it’s trained on lifelike 3D models, it begins with variability, not ideality. Because it embeds geometry, it understands where anomalies matter. And because it ties all stages: design, inspection, process control, into the same spatial frame, deviations can feed back rather than being orphaned.

Put simply: Physical AI transforms brittle AI into spatially aware, context-sensitive intelligence.

We often speak of digital twins in a design or planning context. But what if a twin did more than mirror reality? What if it became part of the running factory? That’s the move toward operational infrastructure.

This is how digital twins mature from visualization tools into decision platforms that operate the factory, not just describe it.

If industry feels like a late entrant to spatial AI, retail has already been using it in the wild. That’s a useful precedent.

Retailers built vast 3D model libraries (of products, environments, packaging, store layouts) to power visual search, AR try-ons, and intelligent merchandising. These models had to be high fidelity, photorealistic, and varied (color, lighting, pose). That scale forced innovations in data generation, variant rendering, and automated asset pipelines.

Retail’s AI journey offers a clear lesson for industry: start with scale, not perfection. Instead of building a single flawless chair model, retailers created millions of variants, enough to teach algorithms how to generalize. They automated their data pipelines, replacing manual 3D modeling with procedural generation, rendering engines, and structured metadata. They embraced the mess of reality: capturing wear, reflections, occlusion, and packaging quirks, because intelligence trained only on clean data fails in the real world. And they never stopped iterating. Every new SKU, finish, and layout fed back into the system, turning retail’s visual infrastructure into a living engine for continuous learning.

In manufacturing, we can adopt the same mentality: don’t treat each new part or fixture as a novel problem. Build a Physical AI bedrock that learns as the product mix evolves.

If you’re a leader in operations, quality, or digital modernization, here’s a starter map:

Industry is littered with AI pilots that never scale. Many baseline systems buckle under real-world complexity because they were never spatially grounded. Physical AI and operational twins offer another way—intelligence that lives in space, not in spreadsheets or images.

This isn’t about replacing domain expertise. It’s about giving machines geometry, and giving your teams the ability to push toward predictability, flexibility, and efficiency.

Where automation makes factories faster, Physical AI can make them wiser. And in a world of unpredictable supply chains, evolving products, and tight tolerances, wisdom is the edge.

About the Author:

Alex de Vigan is the Founder and CEO of Nfinite, a leader in large-scale visual data generation for training Spatial and Physical AI models. Nfinite creates high-quality, IP-free 3D, image, and video datasets enriched with metadata, enabling the development of next-generation AI systems that understand and interact with the physical world. Retail and e-commerce serve as Nfinite’s first application vertical, where its platform delivers scalable, photorealistic product imagery. The company is expanding its impact across industries that require rich synthetic visual data to power intelligent, spatially aware AI.

Read more from the author:

How Enterprises Should Prepare For A Physical AI Future | Forbes, October 2025

The AI Race No One’s Talking About? Data Quality | SwissCognitive, June 202

Scott Ellyson, CEO of East West Manufacturing, brings decades of global manufacturing and supply chain leadership to the conversation. In this episode, he shares practical insights on scaling operations, navigating complexity, and building resilient manufacturing networks in an increasingly connected world.