How material, automation and sustainability are reshaping cold storage manufacturing.

By: Oscar Infanzon, Design Engineer & Manager, Amerikooler

Cold-storage rooms may look like simple metal boxes, but their performance is governed by what lies between the inner and outer walls. Insulation determines how efficient the refrigeration is, how much energy is consumed, how long it resists moisture and corrosion, and, ultimately, how reliably it protects food or pharmaceuticals. As energy codes tighten and operating margins shrink, cold storage manufacturers are rethinking everything from the materials they use to the systems that shape them. The industry is moving toward three central priorities: higher performing insulation, precision driven automation, and more sustainable manufacturing practices.

For roughly fifteen years the industry standard has been foamed-in-place (FIP) polyurethane. The chemistry delivers a respectable R-value on day one, yet its micro-cell structure is vulnerable to two forms of degradation. First, the blowing agents that create the foam’s closed cells migrate out over time, a phenomenon known as thermal drift. The result is a steady drop in resistance to heat flow. Second, the open edges and microscopic voids readily absorb water. Operators who disassemble aging walk-ins often discover rust bands and soft, spongy spots where moisture accumulated over time, causing the foam to collapse

Service technicians see the effects in the field: compressors cycle more often, evaporators struggle to defrost, and energy bills inch upward year after year. Compounding the risk, most FIP panels ship with no meaningful long-term thermal warranty, leaving owners to absorb repair or replacement costs sooner than expected.

Extruded polystyrene (XPS) addresses those weak points at the molecular level. Formed as dense, closed cell boards, XPS locks in its blowing agent early in the manufacturing process, so the R-value stabilizes and remains essentially unchanged for decades. Independent lab tests show water absorption of less than one percent by volume, considerably lower than FIP or expanded polystyrene.

The durability translates directly into operating savings. Panels that resist moisture do not lose R-value to trapped water, and surfaces stay structurally sound instead of degrading near the floorline. When owners run lifecycle analyses, insulation that holds its R-value delivers a clear,long-term drop in refrigeration energy use—often a noticeable share of the walk-in’s annual consumption—compared with panels whose performance drifts as they absorb moisture or lose blowing agents.

Even the highest-performing insulation fails to deliver if installed improperly or manufactured inconsistently. Gaps at joints or thresholds compromise thermal performance and cause long-term energy loss. As a result, the move toward XPS has coincided with advances in panel fabrication, ensuring tighter fits and more reliable energy efficiency.

Some manufacturers have moved away from traditional foaming and toward digitally integrated production lines tailored to board-based insulation. In these facilities, CNC routers cut each XPS panel to a unique digital blueprint, ensuring a precise, gap-free fit. Robotic press brakes form the metal skins to exact dimensions, while barcode tracking and in-line scanning verify each step and improve traceability in real time. This level of precision reduces variability, minimizes errors, and helps maintain the performance potential of high-quality insulation.

These advancements aren’t just about thermal performance; they also improve production timelines. Orders that once took six to eight weeks to fulfill can now ship in as little as two, even for custom walk-ins. As a result, manufacturers are able to meet tighter construction schedules without compromising quality or energy efficiency.

Amerikooler, a leader in commercial refrigeration solutions, was one of the first major walk- in manufacturers to fully adopt XPS as a standard, not just as an option, across all of their custom and quick-ship products. What sets them apart, however, is how their highly automated manufacturing process supports the full performance potential of XPS.

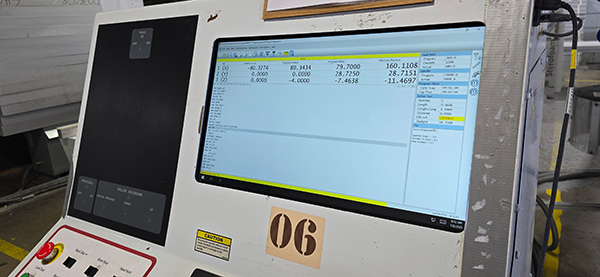

The company’s Miami-based facility has evolved significantly over time, replacing older, manual practices like jigs, tape measures, and handwritten labels with an almost fully automated panel production line. Automated systems precisely shape each panel’s insulation board and form metal skins to exact specifications, with quality assurance checks integrated at every stage of production. Advanced barcode tracking and in-line scanners capture detailed data points in real time, providing complete visibility into each job’s progress. This end-to-end automation not only guarantees exceptional quality and tracking, but also enables us to efficiently produce custom boxes to order, which eliminates the need for warehousing preset panel sizes. Rigorously minimizing variability and safeguarding product integrity allows Amerikooler to deliver systems that provide exceptional benefits far beyond mere speed.

In cold storage design, energy efficiency is a long-term performance metric. When insulation maintains its integrity over time, walk-ins require less energy to keep temperature stable. Panels that resist moisture and thermal drift help reduce compressor runtime, limit system strain, and support lower utility costs across the equipment’s lifespan.

Energy use is just one part of the sustainability equation. Forward-thinking manufacturers are also reexamining how panels are built and what happens to the materials that don’t make it into the finished product. Some facilities now bale XPS insulation off-cuts for return to the supplier, where they’re reprocessed into new board stock. Metal scraps are diverted to recycling streams rather than waste bins, and digital fabrication techniques are reducing the number of miscuts or reworks on the production floor.

Precision driven systems also help reduce overfill and chemical waste often associated with foamed-in-place insulation. By adopting recyclable board-based insulation and refining manufacturing to eliminate unnecessary material use, producers are helping end users reduce both operational emissions and embodied carbon. For facilities navigating stricter energy codes and ESG reporting requirements, these improvements in material selection and production control can offer meaningful, measurable benefits across the product’s full lifecycle.

Adapting to new regulations, such as state-level restrictions on certain finishes, updated refrigerant standards, and evolving sanitation codes, has also driven manufacturers to select more durable, corrosion-resistant materials like Acrylume and 304 stainless steel for panels and hardware. These choices not only ensure long-term product integrity but also help cold storage systems meet the highest standards for safety, durability, and compliance. Additionally, our internal R&D engineering department works closely with sales and customer service teams to continuously drive improvements in design, quality, and manufacturing processes.

As the cold storage industry evolves to meet today’s demands, insulation can no longer be treated as a static commodity. The transition away from foamed-in-place polyurethane toward more durable, board-based alternatives like XPS marks a meaningful shift in how cold rooms are designed and built. Yet, material choice is only part of the equation. The rise of precision automation and closed-loop manufacturing is ensuring that insulation performs as promised—not just on day one, but for decades to come.

The next frontier is intelligent cold storage: manufacturers are now investing in smart systems for inventory tracking, humidity and temperature control, automated alerts, and remote monitoring. These innovations promise to further enhance reliability, efficiency, and traceability across the cold chain. At Amerikooler, ongoing R&D is focused on integrating these intelligent features into future product lines, reflecting a broader industry commitment to continuous innovation. By refining processes and embracing new technologies, companies like Amerikooler are helping to set new benchmarks for performance, sustainability, and long-term value as the industry moves toward a smarter, more resilient future.

Scott Ellyson, CEO of East West Manufacturing, brings decades of global manufacturing and supply chain leadership to the conversation. In this episode, he shares practical insights on scaling operations, navigating complexity, and building resilient manufacturing networks in an increasingly connected world.