Are todays’ first-mile supply chain disruptions simply the new normal and what can organizations do to survive in this new environment?

We supply chain professionals find ourselves in a completely different world than the one we operated in prior to 2020. For example, the ready availability of cheap freight capacity and the negligible inbound freight costs in COGS calculations have vanished. Evidence mounts for increasingly frequent supply chain disruption and geo-political instability that will continue to add to our economic uncertainties and inform our professional decision making. All signs point to a new, disruption-heavy normal that supply chain professionals will have to navigate in the years to come.

To adapt supply chain operations successfully to new global realities, companies must prioritize new investments in first-mile technologies and service provider relationships. They must put a premium on greater supply chain transparency and collaboration. Improving resilience with increased flexibility and supply chain visibility is critical in the face of higher costs for almost every source-make-move decision going forward. How did the first mile get to be so important? COVID-19.

In 2020, soon after the pandemic hit, efforts to mitigate illness risks quickly surpassed manufacturing and supply chain priorities at many companies. Demand for PPE and medical devices boomed as factories shut down and travel and transport barriers were imposed. Unexpected consumer buying trends emerged during lockdowns that shifted import/export trade volumes far out of balance. Freight rates began to surge in late 2020 both internationally and domestically and remain historically elevated today.

Also in 2020, consumers stuck at home diverted their spending to household needs, and the steady growth of ecommerce exploded to more than 21% of Total US Retail sales. More telling, the Pitney-Bowes Shipping Index recorded a whopping 37% increase in parcel volume in 2020, vs. average annual growth of 10% the previous five years. The last mile was getting more costly and challenging.

In 2021, parcel problems receded and were replaced by ocean shipping issues symbolized by the pile-up of container ships outside the ports of Southern California. When a container ship became wedged in the Suez Canal, companies watched in alarm knowing they might soon have nothing with which to fulfill customer orders if they couldn’t gain better control of the first mile of their supply chains.

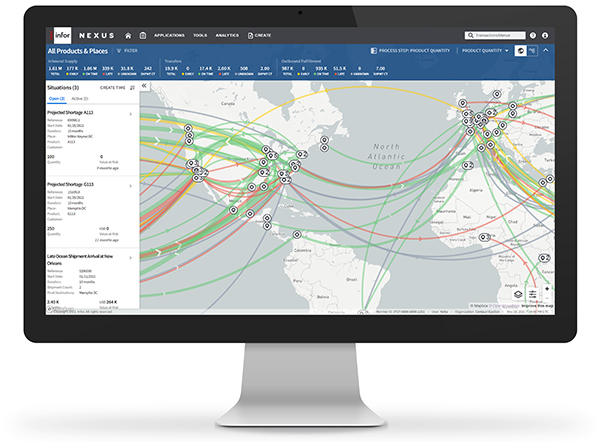

There has never been a more strategic time for businesses to upgrade their first-mile supply chain technologies. While many may understand that multi-enterprise business network application platforms can help them to increase transparency, visibility, and control along the first mile, there are other strategies that should be considered immediately.

Supply chain professionals will be strategizing over the next 2-3 years to optimize service and costs in a global environment where many of the old rules no longer apply to the first mile. It is imperative that technology support the breadth of information, partner and provider connections, control and visibility that are needed to emerge successful from the present storm of uncertainty.

Monica Truelsch is Senior Director of Supply Chain Management Strategy at Infor, the world’s third-largest ERP software company, where she supports the Supply Chain Management product group globally. She joined Infor from Trimble, a world leader in geo-spatial technologies and transportation applications. Her career includes roles in product management, marketing and sales leadership for advanced technologies in telematics, domestic transportation management, chemical handling, engineered materials, artificial intelligence and industrial laboratory management.

Scott Ellyson, CEO of East West Manufacturing, brings decades of global manufacturing and supply chain leadership to the conversation. In this episode, he shares practical insights on scaling operations, navigating complexity, and building resilient manufacturing networks in an increasingly connected world.