A connected data stream, developed through a digital thread strategy, helps product teams improve workflow efficiencies at all stages.

By Rodrigo Britto Maria, Strategy Engineer, Aras

Modern product development moves at a relentless pace, requiring efficient workflows, transparent information flow, and seamless collaboration to keep up with marketplace demands. In the past, product lifecycle management was handled in task-specific silos due to the limited interoperability of legacy PLM systems. This approach severely stunted opportunities to pursue projects that required agility, cross-disciplinary communication, and real-time knowledge-sharing.

Fortunately, a combination of modern technology and a unification strategy — the digital thread — transcends traditional data silos to establish a connected and integrated data stream. This empowers product designers and other key players with a holistic view of the product lifecycle and its potential.

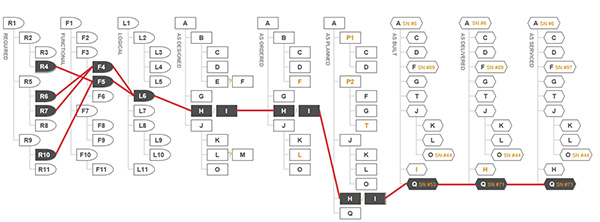

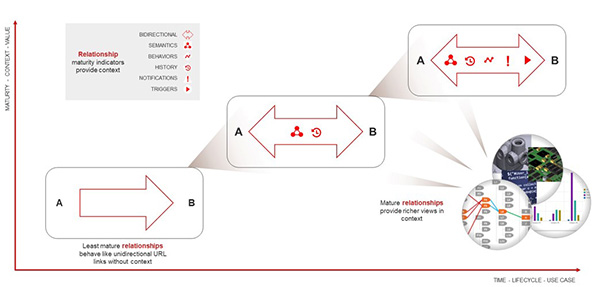

The digital thread maintains meaningful relationships among all a product’s digital assets – and their revisions over the lifecycle – across multiple domains throughout an enterprise and the supply chain. This includes everything from initial product planning to conceptual design, engineering, production, versioning, and end of life. A digital thread creates a real-time, accurate, traceable, and contextualized data stream across these stages as well as the various teams and software that are part of each stage.

By unifying all of these processes and data sources through a single source of truth, users gain greater visibility into the product lifecycle, understand through context why and how each part of the lifecycle operates, and identify current gaps or areas for improvement that might otherwise fly under the radar. They can better visualize how design decisions translate into manufacturing, anticipate service issues that may arise during the product’s lifespan, and incorporate customer feedback more proactively as they plan for future iterations.

Legacy PLM systems often suffer from fragmented data that leads to inefficient operations, communication gaps, and significant errors in the final product. That’s why the modern digital thread strategy relies on modern technology, namely cloud-based platforms and data management solutions that break down silos. Through these technologies, businesses can organize and manage their data from across multiple sources, ensure all users have the appropriate level of access through role-based access controls, and maintain data quality and updates through a more uniform and accessible interface that may even include native security and analytics capabilities for better outcomes.

It’s important to note that the digital thread is not designed to eliminate the software and other resources that are already part of each team’s daily operations; computer-aided design (CAD), model-based systems engineering (MBSE), simulation process and data management (SPDM), and other PLM tools are crucial components of developing a functional product today.

Instead, a strategic digital thread, bolstered by the right cloud platform, ensures an organization’s most crucial data and processes are updated and shared so all users can make data-driven decisions in their section of the product lifecycle. This approach eliminates many data errors, improves transparency, and provides the information necessary for quick pivots and project scalability.

Transitioning to a digital thread strategy can be a complicated process if you don’t prepare and commit to effective change management tactics. To begin your digital thread journey, consider following these steps, tips, and best practices:

Finally, it is not possible or practical to create a digital thread that addresses all of your needs from the outset — any future mergers and acquisitions or internal tooling shifts could derail your thread as soon as you “complete” it. The best way to create a digital thread is through iterative stages that allow you to measure and monitor progress, learn and make adjustments, and refine or pivot your strategy as requirements change over time.

Rodrigo Britto Maria joined Aras 2021. Through engaging product presentations, demonstrations, and workshops, Rodrigo helps customers and prospects discover how Aras Innovator can meet their needs. Before joining Aras, he worked in the aerospace industry, focusing on aircraft design and engineering simulation management. Rodrigo holds a master’s degree in Space Systems Engineering and Management from INPE and a bachelor’s in mechanical engineering from UFSC in Brazil. He enjoys writing, playing sports, traveling, and participating in amateur theater in his spare time.

Scott Ellyson, CEO of East West Manufacturing, brings decades of global manufacturing and supply chain leadership to the conversation. In this episode, he shares practical insights on scaling operations, navigating complexity, and building resilient manufacturing networks in an increasingly connected world.