Supply chain emissions are the next frontier of decarbonization. Achieving results will require supplier engagement and collaboration.

The energy transition is well underway, working its way up global value chains. This conversion is changing how companies operate. Whether shoring up long-term clean energy to power operations or derisking supply chains, the shift away from fossil fuels is rippling through the economy. The move toward low-carbon solutions is forcing every company to look deeply into their supply chain to understand their exposure, resulting in increased pressure on manufacturers to decarbonize.

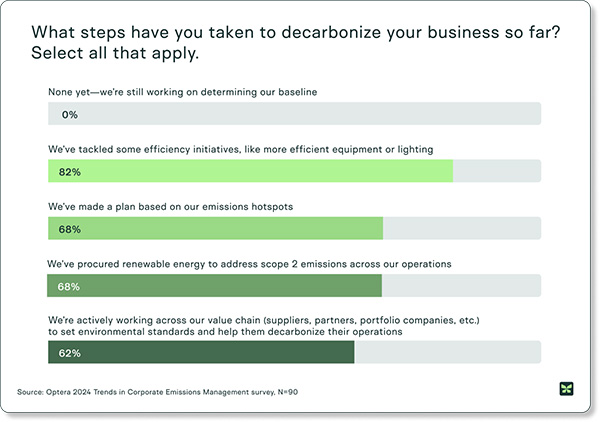

This pressure will compel manufacturers to accelerate their pursuit of decarbonization in 2025, expanding their focus to include emissions from their value chains (scope 3 emissions). The value chain accounts for 11.4 times more greenhouse gases than manufacturers’ owned emissions (scope 1 and scope 2), which means decarbonization is not possible without addressing their suppliers’ practices. According to an Optera report, nearly 70% of surveyed organizations are already actively engaging with their suppliers and partners to reduce their carbon output.

The business case for decarbonization is clear. Regulations requiring businesses to disclose their emissions and climate risk across their value chain impact nearly every large business globally. Renewable energy sources are cheaper and more financially stable than fossil fuels. Additionally, investor pressure for supply chain sustainability has significantly increased, while corporate buyers rank sustainability as one of the top three purchasing criteria. U.S. consumers are willing to pay a 10% premium for environmentally friendly products.

The Optera survey found that brand and product differentiation is a top motivator for tackling emissions. The data also revealed that emissions reporting and goal setting have become standard. More than 90% of organizations disclose their emissions either to the public or to regulators and customers. Nearly three-quarters have set science-based decarbonization targets, and 46% include scope 3 in their objectives.

While the majority of these organizations are moving toward full carbon reporting, the journey will not be easy. Successfully achieving decarbonization targets across scopes 1, 2, and 3 requires quality data and supply chain collaboration.

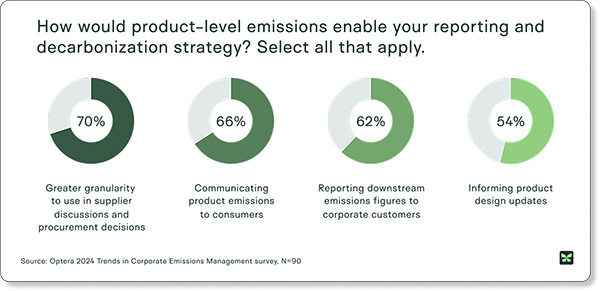

Optera’s survey found that 70% of respondents would use product-level emissions data, which provides insights into the environmental impact of individual products, to inform supplier and procurement decisions. Calculating this information requires granular data, which is currently challenging for many manufacturers to collect from their suppliers. Data inconsistency, quality, complexity and manual collection are commonly cited hurdles.

To enhance the consistency, quality and comprehensiveness of emissions figures, manufacturers should establish standardized tracking and reporting methodologies and centralize data. Purpose-built sustainability and emissions management platforms — whether internally developed or third-party — support data management and remove uncertainty and hassle. As corporate climate programs mature, such solutions will become imperative for accurate calculations and actionable reduction plans.

Regulatory expectations make mastering data management even more urgent. The first climate impact reports for the European Union’s groundbreaking Corporate Sustainability Reporting Directive (CSRD) are due this year. The State of California will require emissions disclosures starting next year. To comply with these regulations, organizations must shore up their accounting practices by developing a detailed scope 1, 2 and 3 emissions inventory and preparing it for third-party verification.

Even where verification is not legally required, the process can be extremely helpful in communicating sustainability efforts to stakeholders. Three-quarters of companies surveyed by Optera have proactively chosen to pursue this course of action.

As corporate sustainability efforts increasingly focus on scope 3, businesses must develop formal, comprehensive supplier engagement programs. These initiatives will deliver the primary data necessary for precise emissions calculations that inform impactful decarbonization decisions. Effective programs go beyond collecting supplier emissions data to include education, support and incentives.

To productively contribute to decarbonization efforts, suppliers must understand why managing emissions matters and how to accomplish that task. Manufacturers can empower their partners to drive change by delivering comprehensive training programs focused on carbon accounting and reduction strategies. Interactive workshops, easily accessible resources and knowledge-sharing platforms will further enhance suppliers’ ability to report the data that manufacturers need.

Because suppliers increasingly bear responsibility for emissions management, manufacturers can achieve greater supply chain emissions reductions by providing their partners with additional support. Initiatives might include technical assistance, strategic guidance, or collaborative efforts like streamlining or developing new processes.

Motivating partners requires both incentives and accountability. For example, companies can extend preferential contracts, financial discounts, and recognition to suppliers with successful sustainability initiatives or penalize underperforming partners.

Industry collaboration to establish universal standards will also help encourage the widespread adoption of sustainability practices. Suppliers know they must comply with these expectations to do business.

Like any other business function, carbon reduction strategies will change from year to year. Driving improvements requires:

The transition to the low-carbon economy is underway, and its impact will be profound. The businesses that will be most successful in the long term are preparing now. But it’s not a solo effort: The outcome of individual corporate initiatives increasingly depends on partnerships. By working together, businesses can achieve far greater impact than they could alone. Reaching net zero will take years of incremental progress, but each small step contributes to the greater goal.

About the Author:

Tim Weiss, Co-Founder and CEO of Optera, has spearheaded thought-leading work with the World Economic Forum and Fortune 500 companies across many industries. Prior to Optera, Tim worked for AES Distributed Energy and Uncharted.

Scott Ellyson, CEO of East West Manufacturing, brings decades of global manufacturing and supply chain leadership to the conversation. In this episode, he shares practical insights on scaling operations, navigating complexity, and building resilient manufacturing networks in an increasingly connected world.