AI Engineering has the potential to transform manufacturing. Here’s how industry leaders can drive that process.

By Pramod P. Khargonekar, ERVA Co-Principal Investigator; Distinguished Professor of Electrical Engineering and Computer Science and Vice Chancellor for Research, University of California, Irvine

The power of artificial intelligence to transform industry is often taken as a given. However, there is a gap between expectations and implementation that many industry leaders are not addressing. One essential element in the AI transformation equation is the need to proactively bridge two crucial fields: AI and engineering.

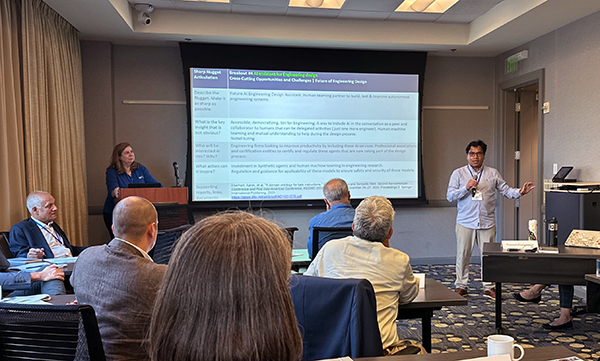

The strategic convergence of AI and engineering, envisioned as AI Engineering, represents a generational opportunity to supercharge engineering to transform manufacturing. This was the premise of a recent report, AI Engineering: A Strategic Research Framework to Benefit Society, on which I was the lead author. The report was the result of a two-day visioning event in late 2023 involving researchers, industry leaders, policymakers, and other stakeholders convened by the Engineering Research Visioning Alliance (ERVA), an initiative funded by the U.S. National Science Foundation (NSF).

AI Engineering is a two-way opportunity: Engineering disciplines will bring their domain knowledge, techniques, tools, and culture to create new forms of explainable, trustworthy, and reliable AI-enabled cyber-physical systems. At the same time, increasingly capable AI tools can transform the fundamental disciplines of engineering. They will also transform the major engineering endeavors of design, manufacturing, and infrastructure. To enable this breakthrough and realize AI’s full potential, leaders in government, industry, and academia must work together.

Simply put, the scope for AI Engineering to transform manufacturing is immense. AI Engineering will:

Each of these opportunities holds enormous potential for progress.

As AI becomes industrialized, the process will encompass data science and analytics, machine learning, cyber-physical systems, digital twins, and beyond. As more sensors and smart analytics software are integrated into networked industrial products and manufacturing systems, predictive technologies can further learn and autonomously optimize performance and productivity.

The ERVA report provides four specific focus areas for industry leaders to explore for their organizations. (More detailed descriptions can be found in our report.)

Addressing these four challenges will depend on industry leaders making the research investments necessary to build this emerging discipline. As our report makes clear, government agencies and higher education have critical roles to play in reimagining the engineering profession and upskilling the workforce. To that end, manufacturing leaders can accelerate the drive to adoption by offering experiential learning opportunities in industry and curriculum development in partnership with education institutions. Transforming manufacturing through AI must be a collaborative strategy to successfully overcome the challenges and transform manufacturing through AI Engineering.

Pramod Khargonekar is Distinguished Professor of Electrical Engineering and Computer Science and Vice Chancellor for Research at the University of California, Irvine, and Co-Principal Investigator at the Engineering Research Visioning Alliance (ERVA), an initiative funded by the U.S. National Science Foundation (NSF). He earned a bachelor’s degree in electrical engineering in 1977 from the Indian Institute of Technology, Bombay, India, and master’s degree in mathematics in 1980 and doctoral degree in electrical engineering in 1981 from the University of Florida. He also served briefly as deputy director of technology at ARPA-E, U.S. Department of Energy in 2012-13. He was appointed by the National Science Foundation to serve as assistant director for the Directorate of Engineering in March 2013, a position he held until June 2016. In this position, Khargonekar led the ENG directorate with an annual budget of more than $950 million. In addition, he served as a member of the NSF senior leadership and management team and participated in setting priorities and policies.

Scott Ellyson, CEO of East West Manufacturing, brings decades of global manufacturing and supply chain leadership to the conversation. In this episode, he shares practical insights on scaling operations, navigating complexity, and building resilient manufacturing networks in an increasingly connected world.