Digitizing predictive maintenance plans, instructions and procedures increases efficiencies and extends the life of assets.

During the COVID-19 pandemic, as we adapt to remote work and staggered workforces, we have an opportunity to rethink how we currently operate. What do we need to streamline? What are we doing now that may become a permanent part of our new reality? Which employees are qualified or trained to perform a specific task?

We’ve heard of preventive maintenance. We’ve heard of reactive maintenance.

But what about predictive maintenance? And what about predictive maintenance programs during the pandemic, or any large crisis that shuts down business as usual? What can we do now to avoid downtime and stay efficient? Are you tracking asset data now in order to build predictive maintenance into your future workflows?

Predictive maintenance means that we create maintenance plans that predict problems before they happen. We can take care of assets to increase their reliability, especially when staff turnover and market uncertainties require efficiency and cost-savings.

Social distancing, according to the Centers for Disease Control and Prevention (CDC), as well as additional public health measures, along with new efficiency measures, may mean that employees come to work in isolated shifts to perform specific jobs. They may leave before or just as the next isolated shift comes in.

As people move from job to job within and between companies, unwritten knowledge and skills disappear from the workplace. Today’s modern workforce requires companies to build a mobile knowledge base where employees can find predictive maintenance SOPs when and if they are called to take on a new task.

Digitizing predictive maintenance plans, instructions, and procedures increases efficiencies and extends the life of assets. Predictive maintenance also enhances the productivity of your workforce.

Pivoting from a pure reactive maintenance program to preventive or predictive maintenance creates the flexibility and quality control we need right now to ensure safety, efficiency, and productivity.

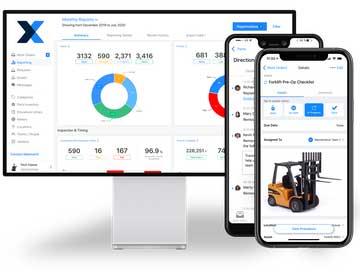

Through modern computerized maintenance management systems (CMMS), we can use historical insights and predictive insights to monitor and manage asset performance data during normal operations to anticipate and predict equipment failures. In other words, rely less on your smartest technicians to catch everything, and empower them with software to free up their bandwidth to become more efficient.

In this time of economic uncertainty and health and safety restrictions, predictive maintenance optimizes online data collection by conducting maintenance only when completely necessary.

Predictive and preventive maintenance as a quality assurance strategy works to ensure asset maintenance is completed at regular intervals based on time or use.

Such maintenance reduces unplanned downtime. Performing an oil analysis or a vibration analysis and recording the data provides the historical data needed for predictive maintenance.

Predictive maintenance eliminates the inefficiencies of both reactive and preventive maintenance by using condition monitoring (CM), or condition-based monitoring (CBM). Monitoring the specific condition of an asset or part identifies any change that indicated a developing fault in the asset.

With predictive maintenance, as a piece of equipment is monitored, clear warnings can alert maintenance teams before the asset goes offline. Even with a modern preventive maintenance system, escalation protocols can quickly alert appropriate personal remotely. These alerts are especially important as the pandemic changes staffing and efficiency is key to productivity and profits.

Predictive Maintenance relies on a successful maintenance program and quality assurance plans to be in place. Maintenance teams need to follow Standard Operating Procedures to collect and input real-time data on equipment and assets. Online checklists and inspections will alert managers when predictive maintenance work is necessary.

Workers rely on online reporting of sensors that monitor equipment performance and send out alerts when performance thresholds are reached. Once real-time data is posted, maintenance workers can carry out the predictive maintenance required to keep the asset online. The goal of sensor monitoring is to keep an eye out for signs that a breakdown is likely to occur.

During social distancing protocols with COVID-19 cases on the rise, workers–experienced or inexperienced–can follow online step-by-step Standard Operating Procedures to check and report real-time sensor data to complete online checklists and equipment inspections. Through such continuous monitoring, managers can gather the data to build even better predictive models.

The best predictive maintenance plans and strategies work when processes are updated and available in real-time. Real-time works best when it is digitized and available anywhere and anytime.

Cloud-based solutions can track assets and control the daily maintenance operations, such as safety inspections, quality inspections, and operating checklists – all with a digital audit trail. 76% of blue-collar workers think it’s important for their companies to use modern technology solutions to assist them with their work.

With staffing thin, efficiency more important than ever, knowing how everything is running–even when you are unable to be on the floor, in the warehouse, by the equipment–can make all the difference between uptime and downtime.

A predictive maintenance strategy will only succeed if you update your processes to leverage its advantages. For example, rather than having the sensor trigger an alert, you could alter your processes so that certain alerts automatically generate the necessary work orders and pass them along to the scheduler.

Predictive maintenance plans avoid DOWNTIME and reduce maintenance costs, especially if a company has been relying on reactive maintenance. Maintenance activities are performed only when needed.

Successful predictive maintenance relies on interpreting and analyzing the data in real-time.

Real-time data is the lifeblood of effective predictive maintenance, especially when the safety and health of our workers are most important.

Caroline Eisner, Content Writer at MaintainX, is a writer and editor with experience across the profit and nonprofit sectors, government, education, and financial organizations. She has held leadership positions in K16 institutions and has led large-scale digital projects and interactive websites, as well as running her own business writing consultancy.

Scott Ellyson, CEO of East West Manufacturing, brings decades of global manufacturing and supply chain leadership to the conversation. In this episode, he shares practical insights on scaling operations, navigating complexity, and building resilient manufacturing networks in an increasingly connected world.