Manufacturers can leap toward digital transformation with automation but must first understand their problem and how technology solves it.

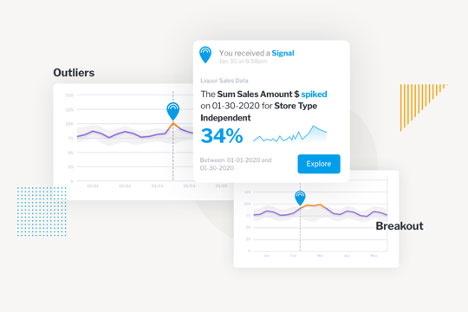

Automated business monitoring tools such as Yellowfin Signals present an easier pathway toward digital transformation, assisting in real-time inventory management. However, with the increasing shift toward automation in the manufacturing sector, it is important to first spend time to identify and understand what problems your business needs to solve, and how such technology can be utilized and adopted.

For many organizations, the act of digital transformation is one of ‘FOMO’ – fear of missing out – which has often led to a problematic rush to adopt new technology. At Yellowfin, we commonly hear ‘buzzword bingo’ with prospects looking at our augmented analytics technology, who request artificial intelligence (AI) or machine learning (ML) capability without being able to articulate what they want to apply that technology to.

For manufacturers, there is an abundance of mature technology that can alleviate problems with manual workflows, and the longer you wait to automate systems or processes, you can be in danger of being left behind. Conversely, if you rush ahead and invest in technology to tick a box without understanding the exact problem it can help solve, you could also be further behind – now just with an expensive, underutilized capability.

Automating inventory management and shifting to digital successfully requires a phased approach.

Source: Yellowfin BI

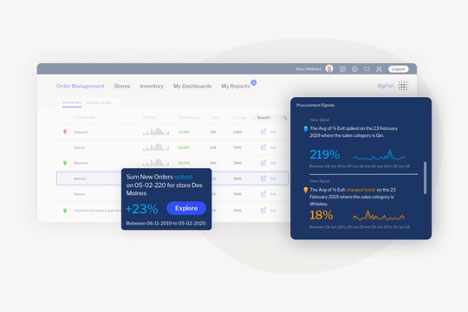

Another challenge to digital transformation is assessing how that technology can be delivered to people in a way they can easily adopt it. This is often a non-technical audience; in the context of analytics for manufacturing, production staff on the floor will approach a dashboard far differently to an in-house analyst. You do not want production managers spending time performing traditional data discovery, but rather a solution that becomes part of their workflow and enhances their ability to perform their core role.

Start by evaluating what problems you need to solve as a priority, look at the tools in-depth, and take the proper time to determine the best-fit solutions for those problems in focused stages.

By dividing the transition into stages, you can acquire wins on the way, learn from smaller mistakes and take your business through that journey toward transformation.

Yellowfin customer KYOWA, a cosmetics and health food manufacturer, is one example of this focused approach. It invested time to first identify what the specific problems it wanted solved were – out of stock (OOS) events – then researched how technology could solve it.

KYOWA discovered its stock outages arose from manual processes and human error, causing opportunity loss. It narrowed the problem down to staff entering inventory count in Excel spreadsheets. This created a reliance on specific people to organize demand planning daily, which led to missed items with a small stock and misjudged timing to order.

With this knowledge, KYOWA was able to understand how automation could help remove reliance on certain users and find the best fit tool in Signals. The automated business monitoring capabilities of Signals could replace previously manual processes through automatic detection and instant notification of important changes in data that led to OOS events.

An example of how Signals brings simplified real-time inventory management into user dashboards.

Source: Yellowfin

But primary to that need was being able to deliver that insight in a way that could be consumed by their team. They understood staff could use Signals and benefit from it immediately, without having to be analysts. KYOWA made sure to integrate that use to this technology in its inventory control workflow, while investing in educating the team on how to maximize its capabilities.

Signals provide automatic detection and notification for specific trends with each product SKU (moving average and confidence interval of number of shipment). This allowed KYOWA to operate more closely in line with real-world product flows and help staff realize real-time inventory management and a simpler workflow to manage stock levels. This resulted in a reduction of their opportunity loss to almost zero within months of going live.

Ultimately, while automation technology like Signals makes the transition to digital easier, it is only possible by first approaching transformation strategically and in manageable chunks, identifying solutions to key problems and taking the business along the journey.

In the current environment we live in, the pressure to go digital is ever increasing. However, it is important to be clear with your own team (and any vendor) on what you are trying to achieve.

Look at a phased approach – iterate and build, as opposed to going too hard in adopting a new unproven technology without a plan. Also ensure you combine this with education around any new tech, as this is critical to adoption.

Digital transformation is an ongoing process. If you lay the foundation right, it will set you up on a path to greater success.

Daniel Shaw-Dennis

About the Author

Senior Vice President, Global Strategy and Alliances at Yellowfin, Daniel Shaw-Dennis has over 20 years of experience in analytics and scaling organizations globally. Starting as an analytics consultant for some of the world’s largest companies, including Lion Nathan, UBS, Lloyds of London and Warner Bros, today Dan heads up Yellowfin’s strategic growth and AI-led initiatives. Dan also works with Yellowfin’s largest partners and customers across APAC, EMEA and North America, developing go-to-market strategies for emerging technology. Dan graduated with a Bachelor’s degree in Business Systems from Monash University, Melbourne, Australia.

Contact:

daniel.shaw-dennis@yellowfin.bi

https://www.yellowfinbi.com/

Scott Ellyson, CEO of East West Manufacturing, brings decades of global manufacturing and supply chain leadership to the conversation. In this episode, he shares practical insights on scaling operations, navigating complexity, and building resilient manufacturing networks in an increasingly connected world.