Intelligent identification solutions drive accuracy and efficiency.

By Michael Kaufmann, Director, Market Development, Logistics for Avery Dennison

Tetris is a tile-matching video game created by Russian software engineer Alexey Pajitnov in 1984 for the Electronika 60 computer. Although complex supply chains aren’t a game, loading trucks is often compared to Tetris. That’s because the efficient placement of a multitude of different size, weight and shape parcels into a truck is in many ways like the game’s goal of fitting as many multi-shaped tiles as possible into an on-screen grid.

Among the many key benefits offered by identity solutions is the ability for RFID-enabled intelligent labels to enable winning the Tetris-like challenge of loading trucks. However, supply chain leaders across the enterprise need first to recognize that the supply chain is not a set of standalone “links.” On the contrary, supply chains should be viewed holistically to leverage advances in data infrastructure that enable a total ecosystem of item + shipping specific information across each touch point of a supply chain – including the most efficient means for loading trucks.

In its 2013 report titled Big Data in Logistics, DHL proclaimed that “The logistics sector is ideally placed to benefit from the technological and methodological advancements of Big Data” and predicted “huge untapped potential for improving operational efficiency and customer experience and creating useful new business models.”

Today, the transformation of logistics to a data-based model is no longer a futuristic fantasy. The ability to create a digital id, carry it through the supply chain, capture all transactions along the way, and action against that data, has now become a reality. Intelligent identification solutions exist to optimize item-level data captured at the beginning of a product’s journey, enabling full inventory visibility and accuracy, as well as enhanced routing speed for all partners along the supply chain. With product-level data, supply chain execs are empowered to analyze and make intelligent real-time decisions with the ebbs and flows of demand.

The utilization of item-level data throughout the supply chain enables speed with accuracy that directly impacts the Tetris “endgame” for trucks as they transport parcels from point “A” to point “B.”

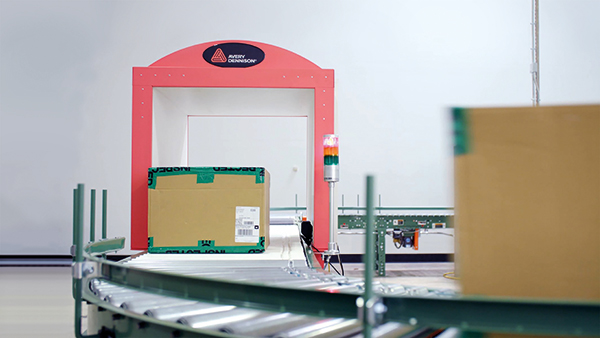

Consider a logistics scenario with an RFID-enabled intelligent label applied at the source of an item. As the item begins its journey, the data captured and carried in that label enables shipment verification: when the “intelligently” labelled products arrive at a facility or warehouse, the recipient can quickly confirm that what was received is precisely what was expected and manage inbound processes for truckloads effectively.

Shipping errors are another logistics challenge that can be addressed through accurate data. Currently, up to 4% of shipping errors are due to misrouted items that must be returned to the warehouse for re-routing. Legacy operations that rely on separate processes (with the 6-8 touchpoints that a product moves through) increase the chance of such errors. Therefore, there is an operational benefit to routing solutions that are based on item or parcel level data to allow cross-docking optimization within the supply chain that enables greater speed and accuracy. Put simply, velocity increases as accuracy improves.

The prevalence of hazardous material in the supply chain is becoming an urgent and dire issue. Among the many items on the FAA’s list are the lithium-ion batteries used in many consumer products each of which require the special markings and/or labels and have their own specific requirements for placement in cargo.

Sorting solutions that use digital product identities currently exist to alert shippers where hazardous items should and should not be placed. The Federal Aviation Authority (FAA) requires these items to have “Hazardous Material” markings and/or labels. There are significant financial penalties for incorrect shipping identification, accruing fines that can amount to over $78,000 per instance. Supply chains certainly cannot afford to inaccurately route load hazmat cargo.

Data captured and carried in intelligent labels provide real-world efficiency solutions for achieving sustainability. One of the areas in which supply chains can address carbon emissions is in the transport of goods. One of the factors that deters sustainability is trucks not being loaded to their full capacity meaning more trucks are on the roads than necessary.

In fact, our own studies have shown that up to 14% more volume can be loaded into a truck by utilizing key data that consider size and weight of parcels, creates the most efficient delivery route, and considers other variables such as perishability. Clearly, such sustainability initiatives have potential to lower costs as well.

The benefits of a data-enabled logistics eco-system will enable supply chain executives to win at truck-loading Tetris. RFID intelligent label solutions at the source of an item will carry it efficiently, accurately and sustainably through all of the touchpoints along the supply chain – in-the-truck, and beyond.

Michael Kaufmann is Director, Market Development, Logistics for Avery Dennison. The company recently launched its atma.io connected product cloud platform that gives unique digital IDs to physical objects for end-to-end tracking from the source to the customer and even beyond to take part in the circular economy. For more information, please visit Avery Dennison.

Scott Ellyson, CEO of East West Manufacturing, brings decades of global manufacturing and supply chain leadership to the conversation. In this episode, he shares practical insights on scaling operations, navigating complexity, and building resilient manufacturing networks in an increasingly connected world.