Streaming data can help manufacturers gain full visibility of the entire supply chain process and become more reactive to real-time changes.

By Kilvin Mitchell

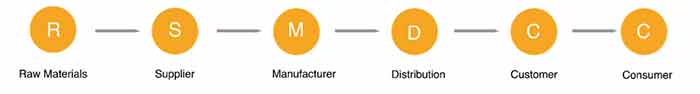

Today’s manufacturers must track and manage a large volume of products across the entire supply chain process (from the acquisition of raw materials and parts to producing the products to distribution and finally to getting the product into the hands of customers). Effectively managing all these moving pieces requires the most recent and best available data; even the smallest delay can result in billions of lost revenue.

But what does real-time data in manufacturing (and specifically, the supply chain) look like? How is it processed? And how can it be used in ML models to optimize the supply chain? Let’s first look at some of the inherent challenges of supply chain management.

Supply chain management is how manufacturers manage the flow of their goods and/or services from production to consumption. This includes the moving and storing of raw materials, production inventory, finished goods, and demand & order fulfillment. Throughout this process, manufacturers rely on various connected, related, or otherwise linked systems and routes of communication to forecast which products customers want and need.

However, accurate demand forecasting that properly aligns the planning and execution of different supply chain processes is difficult to achieve. To arrive at the most accurate forecast and optimize the movement of materials, manufacturers must leverage all information available. They can then leverage this information to integrate demand planning operations with sourcing, production, and inventory management logistics.

More and more, manufacturers are turning to streaming (or real-time) data – any data that is constantly generated and delivered, often by a large number of sources – to alleviate the challenges in supply chain management. For example, web application usage patterns, activities, and operations; e-commerce purchases or returns; social media engagement (shares, likes, link clicks, etc.); or data transmitted from connected devices. IoT data insights, in particular, can help manufacturers monitor equipment and labor, improve operations, manage materials, and optimize the supply chain.

By combining ML with streaming data, manufacturers can gain visibility into various facets of their supply chain. It can provide insight into customer activity, enabling manufacturers to rapidly respond to emerging trends. For instance, tracking changing customer reactions on social media to their brands and/or products can help manufacturers adjust their production schedules toward high-demand products. It also gives them the ability to prioritize budgets for high runner products, while simultaneously eliminating production and warehousing costs for products no longer in demand. Real-time data can also have an impact on fulfillment, by giving manufacturers the ability to reroute a delivery based on real-time traffic conditions.

Real-time (streaming data) has unique traits that separate it from other types of data used in ML models. Batch data, for example, is saved and has all the information available from the beginning. By contrast, streaming data is generated consecutively and is often temporary.

Common characteristics of streaming data include:

These unique traits are what make it difficult for ML models to analyze the data. For example, a machine learning algorithm, mining an average of 2 billion e-commerce transactions per year compiles data from about 3,800 transactions per minute. Given the unrestricted size of streaming data and the speed at which it is delivered, this can cause a major strain on the system being used. This is why manufacturers more often use batch data in supply chain management, as the infrastructure to handle the larger volume may not be feasible.

Analyzing real-time data with machine learning models gives manufacturers the visibility and speed needed to transform their entire supply chain process. At a time when supply chain disruption continues to create shortages and delays for customers, manufacturers need every tool possible to meet customer demands and even anticipate them.

While the benefits of streaming data have typically been limited to companies with a team of dedicated developers, manufacturers without extensive resources can achieve similar results by evaluating their existing technology and team capabilities. A small data science team can make a big impact if they know how to develop, monitor, and optimize models for streaming data. Similarly, leveraging platforms that can integrate into any data ecosystem and are designed specifically for real-time and high-volume computational tasks like data stream mining makes real-time data analysis seamless. By prioritizing streaming data capabilities in both their technology and team skillsets, manufacturers can harness the power of streaming data and ML to optimize their supply chain.

Kilvin is a technical writer at Wallaroo, helping provide technical content in articles, blogs, and other technical documentation supporting the product marketing function. Previously he worked as an engineer for 10+ years in manufacturing and product development, innovating business strategies for manufacturing operations. You can contact Kilvin at kilvin.mitchell@wallaroo.ai.

Scott Ellyson, CEO of East West Manufacturing, brings decades of global manufacturing and supply chain leadership to the conversation. In this episode, he shares practical insights on scaling operations, navigating complexity, and building resilient manufacturing networks in an increasingly connected world.