A new report characterizes how engineering innovation in the natural gas field will dramatically impact America’s energy future.

By Kristen Frey

Ask the average person today about new engineering feats in the energy world and they’re most likely to bring up renewables. While these new and promising forms of energy are undoubtedly deserving of attention, incredible progress in established energy sources like natural gas have largely flown under the radar in recent years as fossil fuels have become a topic nearing taboo.

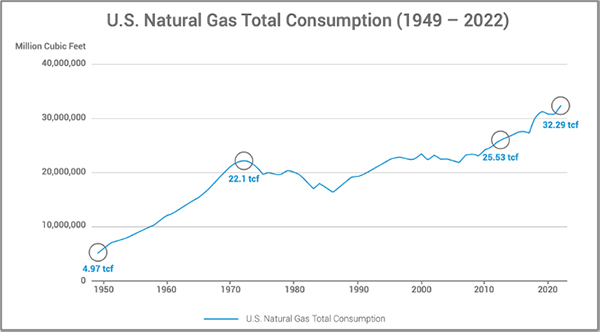

The U.S.’s steadily climbing energy demands, now increasing even more drastically as AI expansion weighs on power supplies, have made it clear to experts that our energy future will be defined by diverse energy sources, including natural gas.

Fortunately, an abundance of natural gas exists in already drilled wells to support these growing energy needs.

A new report from the team at Upwing Energy finds that the remaining natural gas in conventional U.S. wells that are either abandoned or deemed non-economically viable by producers, is enough to power all U.S. housing units for over 11 years – consider that.

The same volume of gas could displace new well drilling and fracking to save emissions equivalent to 8 million cars being taken off the road for a year.

However, until now, a major engineering obstacle has stood in the way of reaching these vast reserves: how to extract the gas efficiently and sustainably. The good news? A new engineering feat has made accessing this previously unrecoverable gas a reality – it’s called Subsurface Compression.

We rely on natural gas to sustain our daily lives in ways most of us never realize. Beyond providing heat or powering our homes and cars, it’s also a crucial component of the fertilizers supporting our crop yields and the produced goods that we use – from fabrics to medical devices and everything in between. Despite this, most people’s understanding of how natural gas is produced is foggy.

The problem is that until now, the industry’s best engineered technology is only able to extract 60% of the recoverable reserves from conventional wells and about 12% for unconventional gas wells. As a result, a well is drilled, partially extracted and then left to drill another well, with significant resources remaining untapped.

This approach had led to gas producers turning to unconventional approaches, like drilling and fracking, as a way to continue producing enough gas to meet rising energy demands despite their being even less efficient and more environmentally harmful.

While this is a simplified example of the core problem facing the industry, it’s deeply linked to the availability of energy worldwide (impacting standards of living), and to the environmental criticisms natural gas takes on.

The goal natural gas technologists and engineers have been working towards for decades has been to extract more gas more efficiently from each well – improving production while reducing emissions related to drilling new wells.

The newly engineered technology, which is now available to gas producers, finally enables near total well recoverability and emissions reductions to the tune of over 8,000 tons of CO2e per well, and is all based on high-speed rotating systems with fascinating roots.

Motor technology first developed for high-speed motorsports, bearings applied in long-term total heart replacements, a drive system used for CO2 removal from the International Space Station and subsea pumps deployed on the ocean floor are all woven into the engineering of the Subsurface Compression System (SCS).

In technical terms, subsurface compression increases gas production and recoverable reserves by decreasing bottom hole flowing pressure and causing higher reservoir drawdown. It carries liquids to the surface by creating higher gas velocities throughout the vertical and horizontal wellbores and prevents vapor condensation by increasing the temperature of the gas when exiting the compressor.

The simplest analogy of the SCS and its capabilities is that of a straw – only in this case deployed two miles downhole where it overcomes incredible pressure, temperature and stress and creates a suction effect enabling the production of gas from the formation even under the lowest possible downhole pressure.

The impacts of this engineering feat are beyond what’s been fathomable in our energy landscape today. In total, in the U.S., we’re sitting on 123.87 trillion cubic feet of additional natural gas that could feasibly be extracted from existing conventional gas wells using this new technology – that’s America’s hidden potential.

For context, beyond powering our homes, this volume of natural gas is enough to meet the entire country’s energy usage for over 4 years; power all U.S. factories for over 59 years; help produce over 582 million tons of acrylic, 1 billion tons of nylon or 2 billion tons of cotton; or produce 5 billion tons of urea fertilizer.

Engineering achievements for traditional energy sources, like Subsurface Compression for natural gas extraction, may not have yet found their way into our everyday discourse like their renewable counterparts, but their impacts will positively impact the abundance, accessibility and long-term sustainability of global energy.

Kristen Frey is the Chief Marketing and People Officer of Upwing Energy, a gas tech innovator and service company.

Scott Ellyson, CEO of East West Manufacturing, brings decades of global manufacturing and supply chain leadership to the conversation. In this episode, he shares practical insights on scaling operations, navigating complexity, and building resilient manufacturing networks in an increasingly connected world.