When market shifts prompt a strategic course correction, operational management must be efficient and nimble in response.

By Peter Follows

Agility has become a requisite for success in the manufacturing industry. Supply chain disruption, demand fluctuations, and rapid technological advancements have created a confluence of disruptive forces that require companies course correct on an increasingly regular basis. This can be seen in the frequency of strategic shifts announced by automakers participating in the EV race, though few manufacturing sectors are exempt. In our rapidly evolving global business landscape, the only constant is change.

Manufacturers are complex organizations. They become increasingly complex as they grow in size, scope, and geographical reach. The intricacies expand when various parts of the build are outsourced to lower cost suppliers, leaving the parent manufacturer to orchestrate the supply, delivery, and storage of parts in concert with the build program.

Shifts in consumer demand, supply and other disruptions add another layer of complexity.

The greater the shifts and the more numerous the disruptions, the more companies build buffers into their inventory system. This is either done formally by adding safety stock, or less formally by simply over-ordering, over producing, or in some cases, hoarding parts. As interest rates rise, these tendencies cause an unnecessary drain on the company’s cash reserves.

These actions (or reactions) are not done maliciously. Quite the opposite, they are attempts by individuals to protect the company’s ability to deliver products to customers. While they may help in the short term, over the longer term they can do tremendous damage to the integrity of the company’s information systems and can reinforce a culture of firefighting.

The efficiency of your operations determines the speed at which you’re able to react to changing conditions. Extreme conditions such as weather and pandemics require highly capable management teams that have the tools and skills to react to unplanned situations. It requires robust and flexible scheduling systems. It also means managers must continuously find ways to improve productivity through streamlining processes, such as simplifying and automating process steps where possible.

As you climb the corporate organization chart, planning time horizons shift from what is happening right now, to what will happen over time. Executives generally focus on capital, product, market, and organizational issues. As you move down the chart towards the point of execution, managers are more focused on shorter term operating issues, like scheduling, production, and shipping product. Front-line managers deal with what is happening now.

Because front-line managers deal with this focal point of execution, they play a critical role in enabling the company to adjust and respond to changes brought about by strategic shifts or external forces. To avoid building and relying on a culture of firefighting, which is not sustainable over time, companies need to build an environment for their managers that provides them with the right tools and training to dynamically manage their operations.

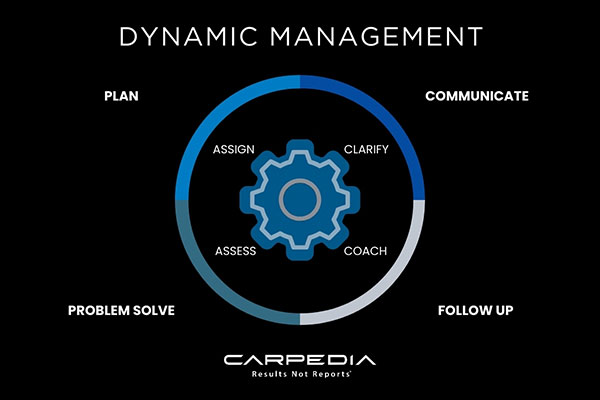

Dynamic management refers to how an individual manages three interrelated things: the process, the performance of the function, and their people. Each of these things influence and reinforce each other, and they need to be considered collectively when changes, whether planned or unplanned, happen.

Many managers live in a reactive environment for the reasons previously mentioned. Dynamic management is the practice of a more deliberate and proactive way for managers and employees to interact and collaborate. It involves assigning work, following up on progress, providing coaching, and correcting mistakes.

Managers are empowered to practice principles of dynamic management when their role is clearly defined, their performance management systems deliver necessary support and visibility, and they are provided with training, coaching, and mentoring. Armed with these tools, managers are free to manage their environment effectively, positioning their organization to respond to shifts in demand and unexpected challenges.

Responding to sudden shifts in strategy requires the same set of operating practices as increasing performance levels – more planning, more interaction, and more problem-solving. If you shut down plants and reallocate product mix, it must be followed by a carefully coordinated execution that requires dynamic management principles to succeed. The more an organization’s strategies change, the more nimble and agile the operations must be.

A change to an organization’s product mix, such as what occurred when automakers shifted to increase their production of Electric Vehicles, often requires a different set of operations, and may require employees with different skill sets. This flexibility to match resources and skills to new demands on the organization can be extremely challenging.

Organizations that are accustomed to uncovering the root cause of variances have a greater understanding of their entire operating system, making them better equipped to adjust to changes – even unplanned ones – quickly and smoothly. If the external factors that create the need for a strategic shift also impact the organization’s competitors, the capability to respond quickly can provide a significant competitive advantage.

Regardless of the cause of the change required, it is crucial to stabilize operations as quickly as possible. The shifts in operational strategies to adapt to external challenges are often most visible to the public. But what sets exceptional companies apart from their competitors is the operational excellence to make these shifts invisible to the customer.

Peter Follows (www.peterfollows.com) is the CEO and co-founder of Carpedia, a global management consulting firm, and the author of Results Not Reports. Carpedia, which helps organizations achieve lasting improvements in performance and profitability, has worked with over 1,000 clients across a wide range of industries, including well-known organizations such as The Ritz-Carlton Hotel Company, H.J. Heinz, Hilton, Delta Airlines, DHL and Yale New Haven Health. As CEO, Follows provides Carpedia’s overall strategic direction and is actively involved in product/service development and market-focused initiatives. He has extensive experience in strategy, supply chain management, and operational effectiveness.

In this episode, I sat down with Beejan Giga, Director | Partner and Caleb Emerson, Senior Results Manager at Carpedia International. We discussed the insights behind their recent Industry Today article, “Thinking Three Moves Ahead” and together we explored how manufacturers can plan more strategically, align with their suppliers, and build the operational discipline needed to support intentional, sustainable growth. It was a conversation packed with practical perspectives on navigating a fast-changing industry landscape.