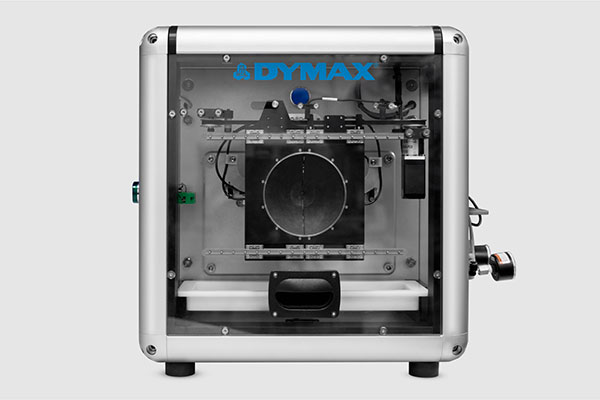

Pneumatically operated system provides consistent material dispense onto cylindrical substrates.

Torrington, Connecticut… Dymax, a leading manufacturer of light-curing materials and equipment, adds the RotoSpense 360 Workstation, a new adhesive application system, to its dispensing equipment line.

The RotoSpense 360’s function allows for one-handed dispensing of annular adhesive rings to the tip of cylindrical substrates, freeing up the operator. This workstation vastly improves the bonding process of plastic tubing and connectors by allowing precise adhesive placement onto component ends repeatedly and accurately, with no need to rely on an adhesive’s viscosity to flow into place. This capability is critical where the exact amount of material is required to correctly fill tubing bond joints without causing overflow, gaps, or voids and reduces scrap from failed bonds and wasted adhesive.

The unit features a fully integrated PLC/HMI (Programmable Logic Controller/Human-Machine Interface) enabling total user control of the system mechanics and part-count tracking. Dispensing valves in the workstation are controlled pneumatically and adjusted from the primary air-supply regulator. The settings menu on the HMI offers the complete operation of the valve rotational speed, dispense time delay, and door open delay. Material flow is further adjusted using the micrometer adjustment located on the top of the valve. The range of viscosities and tube sizes accommodated using the RotoSpense 360 also allows users to vary their operations as needed.

Integrating this system into benchtop manufacturing lines frees up operators’ hands, reduces operator variability, and greatly increases reliability so users can more carefully manage parts and focus on accuracy. Touch-free operation allows for easy collaboration with cobots and automated feeding. The RotoSpense 360 can accommodate a range of adhesive viscosities and tube sizes to meet the user’s operational needs.

About Dymax

Dymax develops innovative light-curable materials, dispense equipment, and UV/LED light-curing systems. The company’s adhesives, coatings, and equipment are perfectly matched to work seamlessly with each other, providing design engineers with tools to dramatically improve manufacturing efficiencies. Major markets include aerospace and defense, medical device, and consumer and automotive electronics.

For additional information on Dymax, visit www.dymax.com or call us at 860-482-1010.

Scott Ellyson, CEO of East West Manufacturing, brings decades of global manufacturing and supply chain leadership to the conversation. In this episode, he shares practical insights on scaling operations, navigating complexity, and building resilient manufacturing networks in an increasingly connected world.