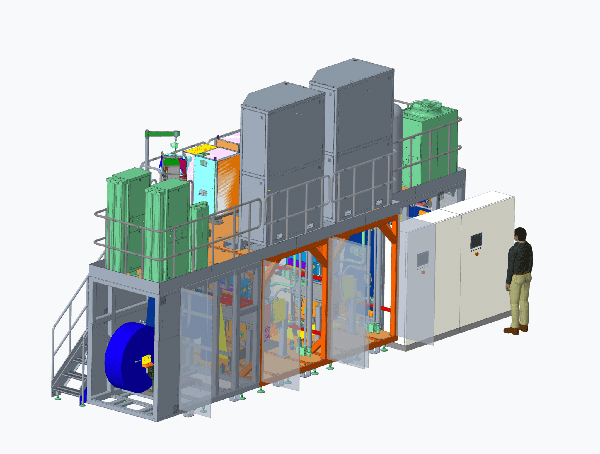

Designing and prototyping an automated food processing and packaging facility.

Ecor International has specialized in designing and manufacturing critical food-contact components for almost 50 years. This extensive experience has enabled it to develop in-depth expertise in the Aseptic Food sector, an area characterized by stringent standards, and to gain recognition from leading companies worldwide.

In addition to its specialization in producing safety- and health-critical mechanical components for food-contact applications, the italian company benefits from the engineering expertise of Il Sentiero International Campus research center. This collaboration allows the company to excel in Rapid Design and Prototyping, Numerical Simulation, Reliability Engineering, Surface Engineering, and Additive Manufacturing.

The product range includes test rigs, electromechanical modules, and automated machines, all rigorously tested for performance by experts at Il Sentiero International Campus. Research efforts are always directed towards achieving industrial objectives, such as enhancing performance and ensuring food safety.

Directed towards achieving industrial objectives such as enhancing performance and ensuring food safety, the objectives of designing an automatic food processing and packaging plant encompass:

– increasing hourly production capacity,

– reducing operating costs and machinery’s environmental impact,

– introducing innovative cleaning and aseptic systems for the machines.

In this case study, we will delve into how Il Sentiero International Campus addressed these challenges, by focusing on key objectives.

The design process started with identifying the client’s needs, followed by a collaborative co-design phase. Subsequently technical requirements and their feasibility were analyzed and, alternative solutions to address any critical issues were proposed. This initial dialogue facilitated the refinement of technical details and the establishment of a shared vision based on efficiency, cost, and performance criteria.

The next phase entailed prototyping, using a combination of hardware and virtual technologies, including numerical simulation and digital twin. A cutting-edge approach, pioneered at the research center, involved generating a virtual numerical model of the machine to predict its behavior and estimate long-term productivity. Concurrently, sensors were deployed on an actual machine, with the results aiding in calibrating and refining the numerical model.

As a result of these actions, the refined numerical model effectively transformed into a digital twin, enabling the determination of the maximum stresses that various machine components would endure during operation. This achievement was made swiftly and at a minimal cost.

The numerical data obtained was utilized to size confined test rigs optimally on the specific areas of interest of the machine, emphasizing stress, load, vibration, and durability tests. This led to substantial cost savings for the customer and an improved accurancy of the results.

“The strategic advantage of having software and expertise in the field of industrial research and development is to provide solutions with significant technical content in short timeframes with extremely low margins of error”, comments Nicola Pornaro, Development & Industrialization Engineering Manager, Il Sentiero International Campus.

This case study illustrates how design and prototyping, driven by innovative technologies and close collaboration with the customer, can result in significant enhancements in efficiency, cost reduction and environmental sustainability within complex industrial sectors like food packaging.

About Sentiero International Campus

Il Sentiero International Campus is an industrial research facility with offices in Schio and Modena, equipped with technical and scientific expertise and equipment that spans the market sectors of automatic processing machines, packaging, and advanced mechanics.

Its laboratories, equipped with analytical instruments and industrial-scale facilities, are made accessible to organizations and companies for the development and prototyping of innovative technological solutions.

Il Sentiero International Campus, together with Ecor International S.p.A., is part of Ecor International Group. Ecor International S.p.A. is a company operating in the mechanical engineering sector that designs, produces and assembles manufactured products using the most innovative production technologies.

| https://www.ecor-international.com/en/ | https://www.ilsentierocampus.com/en |

| Business Areas: | Competences: |

| Aerospace | Additive Manufacturing (3D printing) |

| Advanced Mechanics | Surface Engineering |

| Aseptic Food | Reliability Engineering |

| Pharma | Rapid Design and Prototyping |

| Industrial Research | Joining Technologies |

Scott Ellyson, CEO of East West Manufacturing, brings decades of global manufacturing and supply chain leadership to the conversation. In this episode, he shares practical insights on scaling operations, navigating complexity, and building resilient manufacturing networks in an increasingly connected world.