The facts about printing 2D codes efficiently and with value.

Tuttlingen (Germany) – Ready for the 2D migration? It’s the start of a new chapter in the global supply chain creating opportunities for efficiency, innovation, and value.

The GS1 initiative is reshaping product marking and retail checkout systems. Leading FMCG producers and retailers have already committed to adopting the GS1 2D code standard and are actively driving its development. The challenge now lies in seamlessly integrating reliable 2D printing into existing production processes. Early adopters benefit from greater security, improved efficiency, and a clear competitive edge.

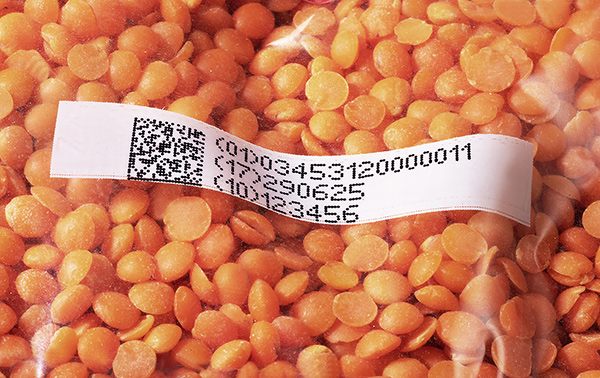

For direct printing on transparent packaging, a proven two-step process is used: first, a LEIBINGER printer applies a white background to create the necessary contrast, followed by printing the GS1 DataMatrix code itself.

This method offers an efficient solution, as it eliminates the need for labels and an entire production step — helping manufacturers reduce costs, save time, and contribute to greater sustainability.

By 2027, industry will enter the pilot phase with a gradual adoption of 2D codes. During this period, products may carry both traditional 1D barcodes and 2D codes.

At the end of 2027, all checkout systems must be upgraded to read GTINs in 2D codes.

From 2028 onwards, manufacturers may decide to rely exclusively on 2D codes. However, this step will remain optional.

A widespread misconception is that linear barcodes will be banned in 2028. This is not the case — they will remain valid. The requirement to ensure readability applies only to POS systems, not to packaging.

Another misunderstanding is that human-readable codes will disappear. This is also false. In regulated industries such as pharmaceuticals and medical devices, as well as for consumer usability, alphanumeric data will remain essential.

Finally, migration is often seen as a one-time switch. In reality, it will be a multi-year transition in which 1D and 2D codes coexist.

Traditional 1D barcodes have been in use since 1974, but their limitations are now evident. In today’s data-driven, digital world, products require far more information than the 13-character GTIN carried in an EAN barcode. A 2D code can store up to 7,000 numeric characters, including: net weight, expiration dates, serial and batch numbers. All of this data can be embedded in a single 2D symbol that is faster and easier to scan from any angle.

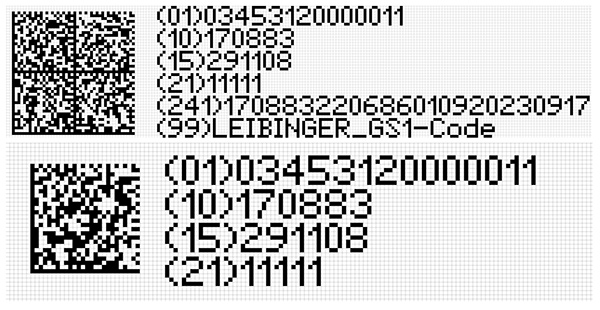

The two most widely used 2D code formats are: QR codes (GS1 Digital Link URI) and GS1 DataMatrix codes (square or rectangular). Both formats provide high data density in a small space while remaining as fast to scan as linear barcodes.

Another important 2D GS1 format is the DotCode, a symbology specifically designed for high-speed printing applications, widely used in industries such as tobacco. The preferred printing method for DotCode is Continuous Inkjet (CIJ), which allows extremely fast and reliable marking even on challenging surfaces.

There is no shortage of general information about GS1 Sunrise 2027. But to prepare effectively, industry leaders need clear, practical insights: What does the new system really mean? How will it affect production processes? Which printing technologies deliver the best results?

In the sections that follow, we take a closer look at the technical and commercial realities of 2D migration — and how to ensure a smooth transition.

In modern supply chains, all partners — from manufacturers to retailers — will rely on 2D codes for product identification. Retail systems are being upgraded, and point-of-sale (POS) equipment is adapting to the new standards. But if a simple scan of a 2D code at point of sale is going to do everything from price lookup functionality to sell by dates, we have to know how best to print them!

Yes — compared to linear barcodes, 2D codes are more complex. They contain much more data and are made up of dense arrays of small modules. While most printers can technically apply a 2D code, the real challenge is printing with maximum readability, at high speed, and at low cost.

In fast-paced industrial production, selecting the right technology — and the right solution partner — is essential.

2D barcodes are made up of a high-density arrangement of black squares, known as modules. Each module is 0.39 mm x 0.39 mm in size, and there is a big difference in how different printing technologies ‘fill in’ this area. For example, the fine points of a laser printer (approx 30 µm for UV laser printing) has to pass over it 13 times. A single drop of ink from a continuous inkjet (CIJ), however, fills the module completely.

This has a significant effect on production speed. LEIBINGER CIJ printers have the fastest drop generators on the market (up to 96,000 drops/second), which is why they are often preferred by ultra-fast extruded cable manufacturers, operating at 1,000m/min.

The latest LEIBINGER IQJET reliably prints 2D codes at speeds of up to 20,000 codes per hour and offers the market’s maximum printhead height — 15 mm. It prints GS1 QR versions up to 33×33 modules in line.

FACT: A UV laser printer requires 13 passes to print a single black square on a GS1 2D code: CIJ printers print the same barcode square with a single drop of ink.

If 2-dimensional codes are going to be easily read by the scanners used both within the supply chain and by customers in stores, there needs to be clear contrast between the white and the black modules.

The fine point size of laser systems is a drawback here too. Laser printers work by “scorching” the material, and the multiple passes required have a damaging effect on the substrate below. This can lead to discoloration of the white space alongside the black, reducing contrast and impairing readability.

Continuous inkjet, however, avoids such issues, by using high contrast inks. LEIBINGER printers offer an innovative heat management feature to ensure consistent viscosity and performance of these specialist inks in varied temperature environments.

Furthermore, the 48-drop resolution of the IQJET ensures sharp module edges, high contrast, and maximum readability.

Because the contrast between the modules is important to the readability of the code, pigmented inks can be very effective when printing against darker backgrounds. Pigmented opaque inks can be easily added to CIJ printers – but this convenient option is not available to users of laser printers and thermal inkjet printers.

In addition to the IQJET, LEIBINGER offers the powerful JET3up PI series — specially developed for printing with high-contrast inks on dark surfaces. Thanks to its outstanding speed, it is particularly popular in the beverage and cable industries.

The technology chosen to meet the demands of 2D codes will affect overall running costs.

For example, while laser printers cost significantly more to purchase than CIJ printers, it is often claimed that laser printing is cheaper in the long run because it doesn’t use ink. However, the opposite is true: the energy requirement for filtration systems and the frequent replacement of filters is a considerable hidden cost, and laser printers require much more electricity.

Add to this the lower purchase price of continuous inkjet technology and it has some compelling cost advantages. Bear in mind also that low energy consumption and frugal use of solvent makes our CIJ printers more sustainable – whereas laser printer users need to dispose of non-recyclable used filters every few months. You can have highly legible 2D codes whilst also reducing operating cost and CO2.

In fact, the IQJET delivers unbeatable TCO with the lowest cost per code on the market. Additional savings come from consistently high uptime, ensured by automatic nozzle sealing and 5 years of maintenance-free operation.

FACT: In a typical 4,000 hour operating cycle printing 2D codes,

laser energy costs are €1700, compared to just €50 for CIJ.*

*Comparison made with 35 W CO2 laser system with 1000 W exhaust

Yes, but there are limitations that you need to be aware of. TIJ is mostly limited to printing on flat surfaces because of the shorter throw distance and the lower velocity of its ink drops.

It also presents a high risk of nozzle clogging, which can lead to missing modules in QR codes, especially at high production speeds. LEIBINGER printers, by contrast, use a fully automatic nozzle sealing system that prevents clogging, removing the need for cleaning cycles that interrupt production cycles.

Due to the small size of nozzles in TIJ, the quantity of delivered ink is limited, increasing the risk of contrast and readability issues. Also, TIJ is unable to use specialist inks. Without pigmented inks to provide contrast on darker surfaces and without fast-drying inks to prevent smudging on non porous materials, 2D code legibility may suffer.

FACT: TIJ printers can’t use MEK fast-drying inks, essential for 2D barcode print at line speeds on non porous materials.

Furthermore, cartridges of the LEIBINGER IQJET printers can be replaced during ongoing production — without any pause or interruption of the printing process. In contrast, replacing a TIJ cartridge requires stopping the line, resulting in lost production time and unnecessary waste. Finally, TIJ inks are 5–10 times more expensive per liter, adding significant ongoing costs.

The seamless transition to 2D codes is an amazing opportunity for producers to streamline logistics and improve the customer experience. And there is no reason that these benefits should come at a cost. At LEIBINGER, we have looked into the technicalities of 2D barcode printing and we are confident that our CIJ printers offer an excellent way for you to make the most of the 2D barcode opportunity – and greet the 2D migration with confidence!

About Paul Leibinger GmbH & Co. KG (LEIBINGER)

LEIBINGER is a global specialist in coding & marking systems with its headquarters in Tuttlingen (Baden-Württemberg), Germany. This third-generation family-run company founded in 1948 employs a payroll staff of around 300 employees. Its primary focus is on the development and production of industrial inkjet printers and inks for use in the marking and coding of products. The solutions created by LEIBINGER are defined by their high quality standards and their innovative technologies. As the inventor of a ground-breaking nozzle sealing technology that makes ink-based marking and coding systems significantly less susceptible to contamination, now with tens of thousands of installations worldwide, LEIBINGER is able to assure higher productivity in the production of food and industrially manufactured products. Through its subsidiaries in the USA and China and its global network of around 150 distribution partners, LEIBINGER is able to maintain a close relationship with its customers right around the world.

Scott Ellyson, CEO of East West Manufacturing, brings decades of global manufacturing and supply chain leadership to the conversation. In this episode, he shares practical insights on scaling operations, navigating complexity, and building resilient manufacturing networks in an increasingly connected world.