The path to autonomy is becoming clear and companies can move wisely along it through a focus on data, design and people.

By Jason Urso, Chief Technology Officer, Honeywell

If you’re in a conversation about the future course of your business, inevitably a portion of that dialogue – if not most of it – will center around the potential for AI to radically impact how you operate. The conversations invariably describe it as an AI “revolution,” but, at least in the industrial space, this “revolution” is actually an “evolution” of automation technology which had used deterministic forms of AI.

In recent years, however, this evolution has brought us to a pivotal moment, an inflection point, leading to a range of new possibilities in the industrial space. It’s akin to the late 1960s, when ARPANET was established – linking research computers around the world – opening a whole new world of collaboration and ultimately leading to the modern internet.

The industrial world is on the cusp of a similar moment in history: our technological sophistication is at a point of critical mass and the potential of AI is limited only by our capacity to imagine it.

Recent Honeywell research shows decision makers in the industrial AI space are dealing with a combination of well-placed enthusiasm coupled with some degree of uncertainty. We interviewed 1,600 industrial AI leaders across 12 global markets, whose companies are currently using deterministic AI to automate industrial processes. Of those surveyed, fully 82% consider their companies to be pioneers or early adopters of AI.

Even though a little more than a third of our respondents (37%) expressed concern that their C-Suites do not fully understand AI, they and almost all their peers (94%) said their corporate leadership is all in.

The AI leaders reported that the top three benefits of AI implementations are:

Additionally, 39% of AI leaders report or anticipate improvements in worker safety.

For many companies, including those who see themselves as pioneers or early adopters, the journey to autonomy is still in its earliest stages. Just 17% of those we surveyed have fully launched their initial plans for AI, and many are still in the scaling (43%) or prototyping (12%) stages. The starting point for each business will be different. Some need to expand the use of sensors and more automated processes. Other more advanced facilities have comprehensive site-wide optimization and are looking to improve insights into assets or move to more remote operations. So, how do we accelerate the pace toward autonomous operations?

When considering the approach to achieving success with industrial AI, three key areas should anchor a company’s decision making: Data, Design, and People.

Every well-functioning, complex operation creates both the intended end-product and reams of data. The more complex the operating environment, the more diverse and detailed the data stream. This is a gift – and taking advantage of AI’s ability to digest, manage, and unlock that flood of data is one part of the path toward our industrial AI future.

Whether it’s a factory with autonomous components, an airplane cockpit designed so that the pilot has improved access to onboard AI support, or even an AI-enabled skyscraper, designing with this technology in mind is central to building muscle in companies around the world.

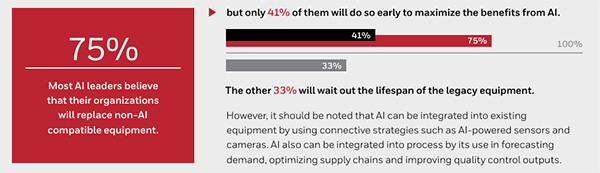

While AI’s importance seems clear, it can also be expensive if you’re working with an existing physical plant or technological backbone. Most AI leaders (75%) believe that their organizations will replace non-AI-compatible equipment, but only 41% of them will do so early to maximize the benefits from AI. The other 33% will wait out the lifespan of the legacy equipment. However, it should be noted that AI can be integrated into existing equipment by using connective strategies such as AI-powered sensors and cameras. AI also can be integrated into process by its use in forecasting demand, optimizing supply chains and improving quality control outputs.

Whether it’s enabling a human to take back the wheel when driving an autonomous vehicle, or to take back control of an automated industrial application, the human capability to respond to unforeseen external circumstances is essential to successful AI implementation. Indeed, when we consider the allocation of resources toward AI, one of the most crucial investments to make is not in the machines, but in the people who will oversee their operation.

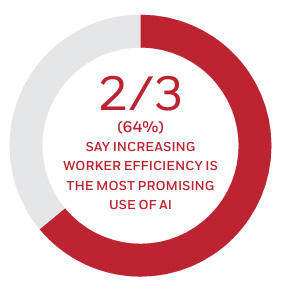

Nearly two-thirds (64%) of respondents to our research cited increasing worker efficiency and productivity as AI’s most promising use in their organizations. Others are focusing on increasing worker flexibility (49%), job satisfaction (45%), and creating more time for skills development (44%) – all valuable for retention. Indeed, bridging the skills gap that is growing wider and wider as the baby boomer generation moves to retirement is a need that AI seems uniquely positioned to meet. To that end, however, it is notable that 81% of our respondents said they underestimated the training resources they needed to introduce AI to the workforce.

While we are all likely to agree that AI is not a cure-all, in this pivotal moment, where every company is at a different place on the path to autonomy, leaders must focus on what the next steps mean for their organizations. It might be starting small with simple applications like streamlining shift scheduling, or diving into more complex applications like harnessing AI to capture and analyze real-time data on factory emissions.

By prioritizing data, design, and people, decisions remain, but that path can be both profitable and productive. Embrace the journey ahead and unlock the full potential of AI in your organization.

Jason Urso is Vice President R&D and Chief Technology Officer at Honeywell, responsible for the design, development and introduction of industrial automation and sensing offerings. Prior to his current role, he was Vice President and General Manager at Honeywell, where he led the global industrial Measurement and Control business within Honeywell Process Solutions. Jason’s two-decade career at Honeywell has grounded his technology expertise and strength in driving global teams of engineers, program managers and support staff to deliver business growth with new best-in-class solutions.

Scott Ellyson, CEO of East West Manufacturing, brings decades of global manufacturing and supply chain leadership to the conversation. In this episode, he shares practical insights on scaling operations, navigating complexity, and building resilient manufacturing networks in an increasingly connected world.