This article outlines a structured approach to industrial equipment disposition, from asset assessment to compliant resale or recycling.

By Luke Crihfield

In asset-intensive industries, idle or outdated equipment isn’t just “old machinery”, it’s a hidden drain on capital, warehouse space, and operational efficiency. Organizations often underestimate the cost of letting surplus equipment sit unused, from increased storage fees to missed opportunities for redeployment or resale.

Without a structured approach, this equipment can turn into compliance risks, environmental liabilities, and productivity bottlenecks.

In this article, we’ll explore the key focus areas for equipment disposition and show how a proactive equipment disposition process safeguards operations while unlocking hidden value.

Equipment disposition is the strategic process of retiring, redeploying, reselling, or recycling operational and non-operational equipment once they reach the end of their productive lifecycle.

It ensures that businesses maximize value, reduce operational inefficiencies, and maintain compliance with safety and environmental regulations. Effective disposition turns excess and obsolete equipment into financial, operational, or sustainable benefits.

When handling operational equipment, a structured approach ensures maximum value recovery, regulatory compliance, and operational efficiency. Businesses must carefully evaluate each piece of equipment and plan disposition strategies to align with their financial, environmental, and operational objectives.

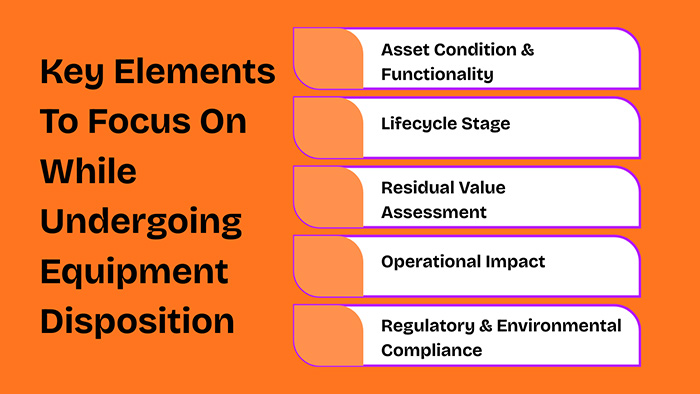

The five key elements to focus on during equipment disposition.

Assessing the current state of your equipment is the foundation of an effective disposition strategy. Determine whether equipment is fully operational, requires repairs, or is obsolete.

This evaluation helps decide the best course of action, ensuring capital is recovered efficiently and unnecessary storage costs are avoided.

Understanding an equipment’s lifecycle stage is a key component of machine asset management, allowing organizations to prioritize retirement or replacement effectively.

Equipment nearing the end of its productive life may demand higher maintenance costs or pose operational risks.

By tracking lifecycle status, companies can schedule replacements strategically, reduce downtime, and maintain smooth production processes without sudden interruptions or unplanned expenses.

Estimating the financial potential of each asset ensures maximum value recovery.

Accurate residual value assessment through proper appraisals and valuation enables data-driven disposition decisions, helping organizations recover capital, support sustainability goals, and make informed choices on disposition.

Every disposition decision has implications for day-to-day operations.

Assess how removing, relocating, or retiring equipment will affect workflows, production schedules, and inventory management.

Planning for minimal operational disruption ensures continuity, avoids downtime, and balances the need for efficiency to optimize asset utilization.

Compliance is non-negotiable when disposing of industrial equipment.

Knowing and adhering to legal, safety, and environmental regulations reduces risk and protects the organization from potential fines or liabilities.

Proper handling, certified recycling, and adherence to environmental standards ensure responsible disposal and align asset disposition strategies with sustainability and corporate governance objectives.

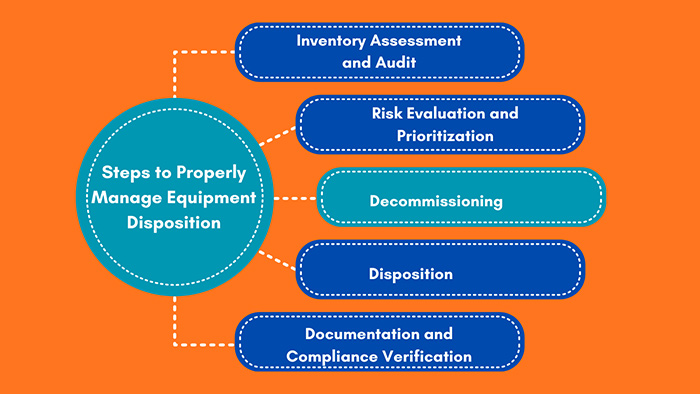

Successfully handling end-of-life or surplus equipment requires a structured approach. The following steps ensure organizations maximize value, maintain compliance, and optimize operational efficiency:

Conduct a comprehensive audit to identify all equipment, including idle, underutilized, or nearing end-of-life assets.

Accurate records of location, condition, and operational status provide the foundation for informed disposition decisions and prevent oversight.

Assess the potential risks associated with each equipment, including operational downtime, safety hazards, and financial exposure.

Prioritize critical assets for immediate attention while planning for less critical equipment, ensuring a risk-aware and cost-effective approach.

Decommissioning is the safe and structured removal of equipment from active operations.

For large capital assets, buyers often cover decommissioning costs and manage logistics themselves. To maximize sale value, keep machinery intact and in place until a deal is finalized. This approach simplifies the transaction and allows the buyer to handle removal on their terms.

Key actions include:

Note: Before moving to decommissioning, always evaluate opportunities for internal equipment redeployment. Repurposing assets across facilities or departments often delivers faster cost savings and avoids unnecessary replacement spend.

Disposition is the final step in converting decommissioned equipment into value. This includes selecting the most suitable channel based on asset condition and operational strategy:

Proper documentation is critical to track every step of the disposition process and maintain audit readiness. Key considerations include:

Industrial equipment disposition is a strategic process that offers organizations the opportunity to recover capital, enhance operational efficiency, and maintain regulatory compliance. By focusing on key elements such as asset condition, lifecycle stage, residual value, and operational impact, businesses can ensure that surplus or obsolete equipment is disposed of in a way that maximizes its value and minimizes risk. A well-executed disposition plan prevents unnecessary storage costs, mitigates environmental liabilities, and supports sustainability goals.

About the Author:

Luke Crihfield is Director of Demand Gen at Amplio, helping manufacturers turn surplus into opportunity through AI-driven growth.

Scott Ellyson, CEO of East West Manufacturing, brings decades of global manufacturing and supply chain leadership to the conversation. In this episode, he shares practical insights on scaling operations, navigating complexity, and building resilient manufacturing networks in an increasingly connected world.