Why we need to treat waste as a valuable resource and not a design flaw.

We are living in a waste crisis where poorly managed waste systems directly contribute to climate change. The world generates around 2.01 billion tonnes of garbage (municipal solid waste) annually. At least a third of this waste isn’t managed in an environmentally safe manner and global waste is predicted to grow by 3.40 billion tonnes by 2050.

We’ve created linear waste systems where we dispose of products instead of considering how to reuse it as part of the circular economy. Globally, we’re missing a huge opportunity because much of the waste we generate can be turned into valuable by-products.

For generations, the treatment of garbage has been ignored, but increased regulation, education, and media attention towards the environmental impact of poor waste management and infrastructure makes it harder to avoid.

But how do you create a circular solution that can transform waste from a climate change liability into valuable resources? It starts with treating domestic sewage and industrial wastewater in a circular manner. Most of these liquid wastes are disposed of through incineration, which is CO2 intensive, expensive and does not recover transportable energy value or reusable products from the waste.

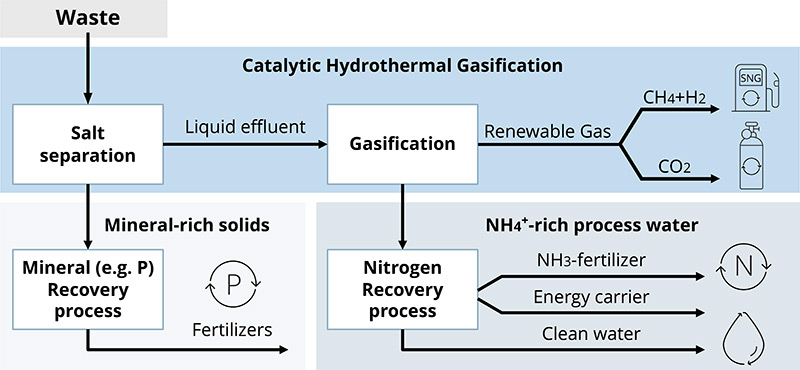

If we implemented sustainable treatment solutions, we would immediately reduce CO2 emissions and capture crucial by-products, including a constant supply of synthetic natural gas that can be injected into the grid network; a pure CO2 stream ready for carbon capture; fresh water for industrial and public use; and salts and minerals including phosphorous, nitrogen and potassium for fertiliser.

The incentives are clear, but we need a better solution. That’s what we’ve been developing at TreaTech, a Swiss based waste treatment company that can convert a range of liquid waste and waste derivative streams into by-products that can solve both economic and climate change issues.

In 2021, the European Union imported ~60% of the energy it consumed, and 40% of that came from Russia. Of the Russian imports, 41% was natural gas. The ongoing war in Ukraine has tightened the global gas market and Europe faces ongoing uncertainty around gas security as it searches for new supplies.

Using technology like TreaTech would enable countries to dispose of waste sustainably and produce local synthetic natural gas that can be re-used by industrial players or injected into the grid, providing a secure feedstock of biogas. If TreaTech treated all the industrial waste and liquid biomass produced in Switzerland each year it would generate 13 TWh of natural gas, equivalent to 83% of Switzerland’s annual imports from Russia. This not only enhances local gas supplies at a time of unprecedented supply crunches for both businesses and consumers, but also improves Europe’s resilience to the sudden spike in wholesale gas prices.

The waste sector is responsible for 10% of global GHG emissions. Of that, liquid waste treatment represents 2.8% of CO2 emissions, and most of this waste is disposed of through energy intensive incineration. In comparison, TreaTech’s circular technology can recycle 99% of the waste value while emitting 94% less CO2 emissions by using three times less treatment space. Plus, TreaTech is also a CO2 negative solution as up to 30% of the produced synthetic natural gas is pure CO2 that can be sequestered or used by multiple industries including agriculture and biofuel production.

Water scarcity affects 40% of the world’s population and climate change continues to accelerate water risks for governments, businesses, and communities. Most industrial and municipal sludge contains ~95% water and even after it’s been dehydrated for burning, the waste is still 70% water. However, any clean water or valuable nutrients are lost when burnt.

Instead of sending wastewater away for treatment, it would be economical for industrial plants to recover water for reuse as “process water” or sell it on for irrigation purposes. TreaTech’s modular technology treats waste onsite and captures clean water and valuable salts and minerals, including phosphorus, nitrogen and potassium, which can be used for fertilisers. Treating municipal sludge this way would allow Switzerland to capture 60% of the phosphorus currently used as fertiliser.

We need to change how we view waste, from being a burden to an opportunity that can address major climate and economic issues. Governments and businesses need to work together and invest in circular solutions that can be embedded into existing waste treatment processes. This is how we transform outdated waste treatment systems and mindsets, and we must start now. Get in touch if you’d like to know more about TreaTech or if we could help evolve your business’ waste treatment options.

About the Author:

Frédéric Juillard is a Life Sciences engineer and entrepreneur with more than 10 years of experience working in developing clean technology. Frédéric founded TreaTech in 2015, based in Switzerland the company harnesses the power of the circular economy, and its innovative product can convert discarded liquid waste into valuable resources in a sustainable and cost-efficient manner.

Frédéric has raised more than CHF 6.8 million in grants and institutional funding for TreaTech from Swiss and European institutions and has increased TreaTech’s headcount to a team of ten full time employees. Together they have created one of the few available solutions that is able to revalue 100% of the by-products of liquid waste – meaning no end products are left unused.

Scott Ellyson, CEO of East West Manufacturing, brings decades of global manufacturing and supply chain leadership to the conversation. In this episode, he shares practical insights on scaling operations, navigating complexity, and building resilient manufacturing networks in an increasingly connected world.