October 30, 2019

Just a few years ago, additive manufacturing, also known as 3D printing, was purely associated with rapid prototyping, research projects and advanced engineering teams. Now, with advancements in printers and materials, many organizations are looking to additive manufacturing (AM) as a timelier and cost-effective production solution. Depending on the application, AM can be used to produce lighter weight and stronger parts or to create timely tooling for casting and injection molding. Either way the industry’s perception of AM is starting to shift from recognizing its unique capabilities and geometries for specific applications to how it could be used in manufacturing capacities, as well as delivering a toolchain that could support design.

Advanced engineering simulation has traditionally been employed as virtual testing of a mature design. Typically, this is a task performed late in product development just before building a physical prototype. Mature digital transformation companies use simulation technology early in the design process as part of concept design. To enable this, simulation driven design software has been created using the same physics as established tools, yet it is developed specifically with a design audience in mind to ensure better and more efficient designs are maximized in AM.

The distinctive organic-looking parts that many consider a trademark of AM, are created through a process called topology optimization. Software delivering this technology uses finite element analysis (FEA) to create efficient geometries that meet design criteria for structural performance. During the concept stage of product development, topology optimization enables designers to explore possible design directions, and understand the effect of changing the loads on the part or the design space it can inhabit.

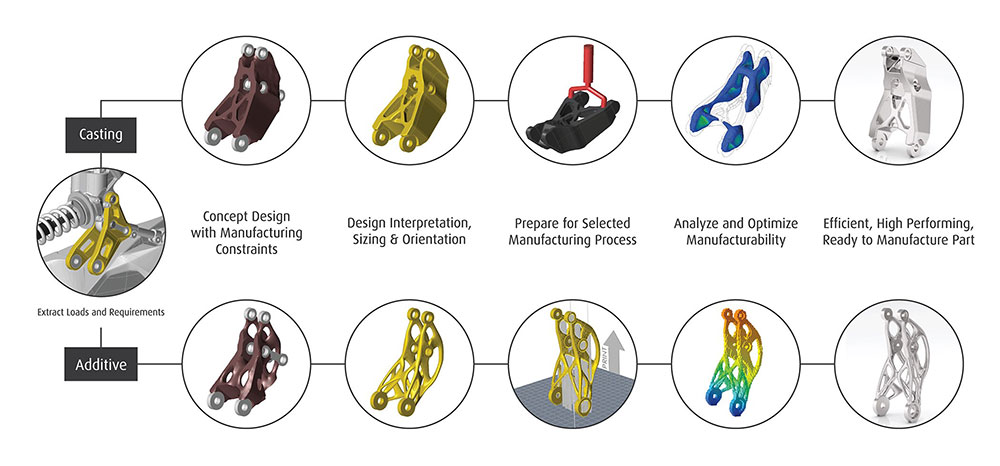

Design workflow to build the optimal part for any manufacturing process.

Additive manufacturing might be an element of the production process, but it’s not essential to the manufacturing method of every part enhanced by digital transformation. For instance, it may not be necessary for certain parts to be produced through AM for cost or volume reasons when it might be important for more timely tooling. Additive methods can be aggressively applied to the manufacture of cores, forms and molds, in addition to production jigs and fixtures.

Rapid tools for injection molding are a result of AM. The reduced fabrication time means that tooling lead times are shorter and the storage of physical tools is less important. Discarding and remaking a tool, or manufacturing more tools if volumes demand, is something AM enables. Similar advantages can be achieved with a hybrid casting process, where molds and cores are 3D printed with sand and a binder printer.

The creation of an effective, manufacturable design requires more than just a topology optimized design proposal, however. The design process also needs to be considered early on. There are two methods that high-performing companies are using to address this challenge. First, they use the manufacturing constraints provided by their topology optimization tool. This eliminates the majority of unproduceable geometry solutions. Second, they apply fast and easy-to-use manufacturing simulations to concept designs. Many teams use both.

To be a successful manufacturing simulation tool for injection molding, casting or extrusion must simplify the use of computational fluid dynamics (CFD) analysis to characterize the material flow and cooling for a design. For example, in the case of an AM injection mold tool, this will inform the use of conformal cooling, a technique that achieves a faster part cooling time. This results in higher productivity through reduced cycle times, in addition to reducing the thermal deviation in a mold, which means better component quality. Conformal cooling lines are hard to fabricate by conventional machining, but considerably easier to manufacture by additive means.

Significant weight reduction, improved stiffness and consolidation of parts are attractive opportunities offered by generative design. For prototypes and some custom single-unit parts, topology optimized geometries can often be interpreted into additive parts in a literal way. Often for parts or manufacturing fixtures, such as robot arm end effectors or check gages, the additional manufacturing constraints for AM must be observed. At volume, AM parts must maintain dimensional consistency, meet cost targets and achieve production schedules.

The geometry of the part and the support structure must be designed carefully. This requires simulation of the design and the manufacturing process. This has often required the use of multiple software tools, but recent developments are consolidating the decision making into a single environment. It is important to remember for most additive processes the material for a part is effectively being built at the same time as the part. New techniques allow efficient virtual testing of micro-scale material characteristics throughout the part. These fast and accurate simulations predict a variety of material behaviors with minimal test data.

As the volume of data relating to AM parts and processes accrues, companies will apply more machine learning to additive production decisions. This technique is already applied in traditional manufacturing businesses. Machine learning can be used to ensure the early design direction aligns with part yield, repeatability, cycle time, production planning goals and reduced costs.

Companies leading the digital transformation are exploiting the huge potential existing at the convergence of model-based simulation and data-driven simulation solutions for every stage of product development. Whether defining more effective design and engineering workflows, using data acquisition to improve operational efficiency or enabling the predictive maintenance of systems in the field, the true potential of combining advanced physics simulations and data science solutions throughout the product lifecycle are just beginning.

As part of their digital transformation, organizations are moving AM from an advanced capability to a production capacity technology. Across industries we’re seeing organizations utilize simulation software to optimize their designs for AM with early manufacturing analysis, including applying machine learning to production decisions, and to simulate material characteristics. It’s the integration of these robust and accessible simulation design tools combined with AM that will lead to more efficient manufacturing methods.

James Dagg, Chief Technology Officer, Design and Simulation Solutions for Altair.

Scott Ellyson, CEO of East West Manufacturing, brings decades of global manufacturing and supply chain leadership to the conversation. In this episode, he shares practical insights on scaling operations, navigating complexity, and building resilient manufacturing networks in an increasingly connected world.