Prescriptive analytics can optimize EV battery quality, throughput, and recycling of costly, strictly mandated import-dependent materials.

The beating heart of an electric vehicle is its battery system. The battery also currently comprises 35 – 40% of the vehicle’s total cost. Meanwhile, essential materials such as lithium, nickel, and cobalt have high import dependency ratios, are expensive, and will prove increasingly harder to come by. Simultaneously, EV battery production and lifecycle policy mandates raise the bar for compliance. Additionally, battery-cell manufacturing is a critical control point in the battery-electric vehicle (BEV) value chain.

These factors combined make technology for improving the battery-cell manufacturing process worth interrogating.

Prescriptive analytics is a cost-efficient solution for optimizing an EV battery line’s quality and throughput. It can also boost the recycling chain dimension of the EV battery-making process.

Electric vehicle OEMs and their Tier-I battery suppliers must scale up gigafactories that continually reduce EV battery production costs per kilowatt-hour while force-multiplying capacity.

However, environmental caveats geared toward net CO2 emissions pose next-level technical challenges. Solving for them means homing in on granular, targeted, and measurable EV battery process efficiency improvements with high relative impact.

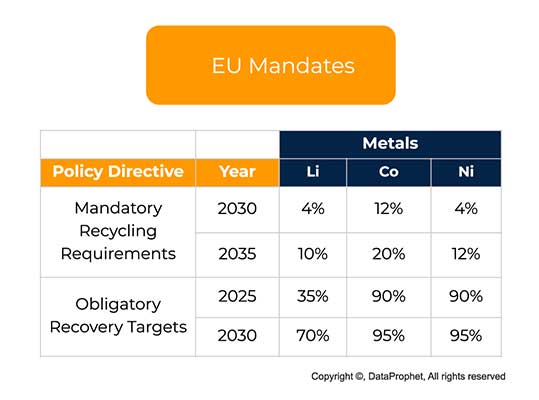

EV battery recycling and raw material recovery processes will be more important in the coming years. The European Parliamentary Research Service considers the lithium-ion (Li-ion) battery market in Europe as an example, stating that raw material recovery and recycling will be mandatory.

Note that in recycling nickel, EV battery manufacturers will need to reuse nearly 70% more of this critical metal in 2035 than they had to in 2030.

Lux Research highlights the related issue of recycling technology and infrastructure — compounded by the circular battery economy challenge of producing EV batteries with the scant availability of recyclable materials. Simply put, there are not enough end-of-life (EoL) batteries with which to work. GRS Batterien, for example, figures that in Europe, 8 million tonnes of EV batteries are produced annually while only 40,000 tonnes per annum are recycled.

The combination of new processes in a demanding market begs for a technological intervention that yields efficiency from complexity. Prescriptive analytics is well-suited to optimize EV battery production and recycling.

The highest-impact data-driven manufacturing solution is prescriptive analytics, served by deep learning discovery. It can ingest hundreds of millions of process data points in a single implementation. For the EV battery manufacturing and recycling process, it can translate the complex, cascading dynamics of the process into a user-configurable interface for operators, delivering 5 – 10 thousand features in a single view.

Why does this capacity matter for EV battery makers?

Leveraging big data allows for a fine-grained accounting of the thermodynamic, physical, metallurgic, and chemical parameters that circumscribe EV battery production. Data scientists can model an algorithm from a contiguous period (as little as 3 – 4 months) that generates prescriptive guidance for plant engineers. Operators then enact preemptive setpoint adjustments to non-critical tolerances.

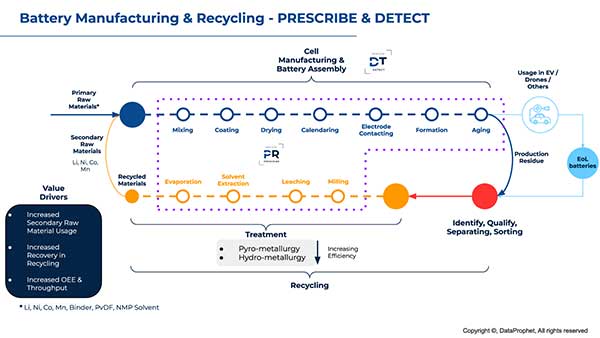

Data-driven optimization of EV battery electrode production factors in nested process variables. These include mixing (temperate, time, and atmosphere), coating (film thickness and coating speed), drying (temperature, speed, and foil pre-tensioning), slitting (tool wear), calendering (process settings), and vacuum drying (processing time).

A prescriptive analytics solution maps the historical performance to the key quality markers—mixing quality, coat accuracy, slitting edge quality, yield rate, and solvent recovery. Batch ID and timestamps ensure traceability to correlate actual production data with the historical optimal. This technique optimizes the yield ramp process with a stable target for achieving the line’s optimal operating region.

In a circular battery economy, EV battery makers utilize production residue maximally, along with the viable remaining materials in EoL batteries. Prescriptive analytics is ideally suited to leverage a mass of production data for this task. Working with manufacturing experts, data scientists can target critical parameters and supply missing ones from the Edge. Deep learning discovery then links previously hidden interdependencies to production outcomes. Prescriptions ensure the optimal grade and maximal recovery of secondary raw materials such as lithium, nickel, cobalt, and manganese in the EV battery production process.

Capitalizing on EV battery demand is a complex undertaking in an evolving supply chain: from mining to cathode-active-material (CAM) production to the most vital phase—making the battery cells. At this critical control point, a competitive advantage is there for the taking. Data utilization can render EV battery production lines more eco-efficient as capacity is ramped up and quality improved. Putting EV battery manufacturing operators behind the automating intelligence of AI-driven guidance means running a gigafactory at its most optimal region for minimum waste and optimal energy efficiency.

Prescriptive analytics is an adaptive, scalable, and non-disruptive technology for next-generation EV battery process control and optimization. Data-to-value solutions also present an opportunity for gigafactories to meet EV battery lifecycle policy mandates defining the next decade.

About the Authors:

Santhosh Shetty is Technical Sales Engineer at DataProphet.

Nicol Ritchie is Technical Writer at DataProphet.

Scott Ellyson, CEO of East West Manufacturing, brings decades of global manufacturing and supply chain leadership to the conversation. In this episode, he shares practical insights on scaling operations, navigating complexity, and building resilient manufacturing networks in an increasingly connected world.